sheet metal vs plate metal Sheet metal, thin and formable, is perfect for intricate designs and lightweight applications. Plate metal, thick and strong, excels in heavy-duty, load-bearing structures. Consider thickness, strength, and purpose when making . The 175 is a great machine. I welded mostly small diameter, thin wall tube. 1 inch and under. It works great especialy at very low settings for sheetmetal work. It is also powerful enough to weld almost anything that you need. I doesn't have a water cooled tip so if you are welding in the 170 amp range you have to watch the duty cycle.

0 · steel sheet vs plate

1 · sheet metal vs steel plate

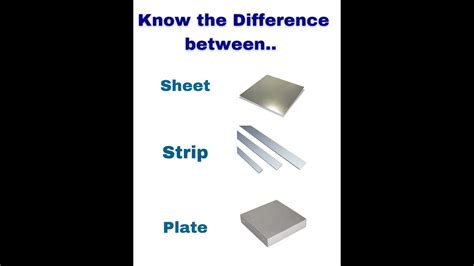

2 · plates sheets and strip

3 · plate vs sheet strip

4 · foil vs sheet plate

5 · flat bar vs plate steel

6 · difference between sheet and strip

7 · aluminum plate vs sheet

My first time TIG Welding mild steel. I've done a little aluminum. I have also gas welded, but that was 18 years ago. Still getting the hang of it.

The primary difference between steel sheet and steel plate lies in their thickness and the specific applications they are designed for. Steel sheets are thinner, typically ranging from 0.5 mm to less than 6 mm in thickness, and . The difference between a metal sheet and metal plate can be defined by thickness. If the thickness of the metal is ¼” (6mm) or more, then it is considered a plate. Plate thickness is typically measured in inches. Steel Sheet: Lighter, making it easier to handle in projects where weight is a concern. Steel Plate: Heavier, providing more stability and . Sheet metal, thin and formable, is perfect for intricate designs and lightweight applications. Plate metal, thick and strong, excels in heavy-duty, load-bearing structures. Consider thickness, strength, and purpose when making .

For Structural Applications: If strength, rigidity, and load-bearing capacity are paramount, steel plates are the preferred choice. For Precision and Appearance: When a smooth finish, precise dimensions, and formability are .

The Difference. The only difference between sheet and plate steel is the gauge (thickness) of the metal. They both have very different uses, depending on the varying .Plate is a flat, rectangular piece of metal with a thickness greater than 6mm. It is typically produced through a hot rolling process, where the metal is heated and passed through a series of rollers to achieve the desired thickness. On the .Generally speaking, a sheet is a thinner item of metal that has been cut from a continuously rolled coil. As such, it can be less than 1mm, or up to 25mm, in thickness. A plate is a thicker item of .

The primary difference between sheet metal and plate rolling is the thickness of the metal used. Sheet metal is typically thinner than 6 mm (0.25 inches), while plate is thicker than 6 mm (0.25 inches). This difference in thickness affects the type of equipment and techniques used for rolling. Equipment

A metal sheet is like your favorite slice of pizza—thin and flexible. Plate metal, on the other hand, is like a thick, hearty slab of meatloaf. It’s substantial and robust. The difference in thickness dictates their strength and . In the world of sheet metal fabrication, buying in bulk often means purchasing material in coil form. On average, rolled carbon steel is 5 to 15 percent cheaper than its sheet metal counterpart. As attractive as 15 percent savings . When working with metal, the type of metal and the thickness of the metal will determine the best bending tool for your project. Sheet metal is typically thinner than 1/4 inch, while plate metal is thicker than 1/4 inch. The thinner the metal, the easier it is to bend. However, thicker metal requires more force to bend. ThicknessOne of the main differences between Aluminum Plate and sheets is that sheet metal is under .249” thick, while plate metal is .250” and above.. Another difference between Aluminum Plate and sheets has to do with the distinct applications for which they are used. Sheets. Sheet is the form of aluminum that is used the most often.

Burbank metal supply is another supplier who has remnants and drops. The owner is a lot more friendly and service-oriented than IMS. I forget the spot, but there is a place in the Long Beach area that does huge amounts of nice clean sheet/plate - they sort and stockpile it, and also list it on eBay. Their prices are reasonable. The thickness of the metal being formed is a critical factor in determining the suitability of sheet metal bending or plate rolling. Sheet metal bending is ideal for thin sheets of metal, typically ranging from 0.01 inches to 0.125 inches. Plate rolling, on the other hand, is used for thicker materials, ranging from 0.25 inches to several inches.So, whether you’re working on a high-tech automotive project or a massive industrial fabrication, the choice between sheet metal and plate metal is a critical one that can make all the difference in the world. The Verdict: Choose Wisely, My Friends. Alright, so there you have it – the epic battle of sheet metal vs. plate metal.Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. The equivalent thicknesses differ for each gauge size standard, which were developed based on the weight of the sheet for a given material. The Manufacturers' Standard Gage provides the thicknesses for .

The plate is a piece of metal which has a thickness of more than 3 mm. It may be of any type of metal like steel, aluminum, etc. Difference Between Plate and Sheet Metal. Plate and sheet are words which we use to describe the classification of metals depending upon their thickness. In addition, plates are typically thicker than a sheet.

steel sheet vs plate

sheet metal vs steel plate

The metal you use will fully depend on your needs. To help you better understand this, here is a quick run-through of the applications of metal sheets, plates, and foils. Metal Plates: Stainless steel plates are commonly used for industrial applications like construction or applications that require hygienic properties. This is why plate metal .

5.3 Thick plates are difficult to source 6 Galvanized vs. Galvannealed Steel - Need Help Selecting the Right Material? 7 Recommended Default Sheet Metal Tolerances; 8 Galvanized vs. Galvannealed Steel FAQ. 8.0.1 What is the main difference between galvanized and galvannealed steel?

A plate is a thicker item of metal that has been produced (rolled) as a single item. Thickness can be up to 150mm or more, but also as low as 2mm from certain producers. Therefore, it’s quite possible that certain thickness items could be produced via either process and described differently, although both are in the hot rolled condition.

Get precision sheet metal fabrication and turnkey contract manufacturing services. Contact us for CNC laser cutting, forming, welding, and more. 262-891-3888 [email protected] Apply Now. Facebook; LinkedIn; Capabilities. Laser Cutting; Punching and Stamping; Press Brake Forming; Weld/Grind/Polish; Shearing .

Many companies have found that aluminum extrusion is the way to go and have decided to move beyond using sheet metal to create their machined products. If your business is looking to gain an advantage while still creating . I have things listed like 3/16", 1/4", 1/2" and 3/8" plate listed as Plate, where as I have another category for sheet metal like: 24 gauge to 7 gauge sheet metal. This means that when ever a search is done for a part number you have to look in another place besides sheet to find the material listed as plate. Sheet metal vs plate steel is a kind of metal material, which is widely used in industrial production and manufacturing. Characteristics of Sheet VS Plate Steel. The plate has a larger area and thickness, higher hardness . If you are looking for a metal product that will allow ventilation, drainage, or perhaps add a decorative touch, your three main choices are Perforated Sheet Metal, Expanded Sheet Metal, or Welded/Woven Wire Mesh.

The difference between sheet metal and plate metal. Sheet metal is thinner and more malleable than plate metal, making it ideal for jobs that require precision, flexibility, and intricate detailing. It’s very popular in industries such as automotive, aerospace, and construction, as there’s a demand for lightweight and easily shaped materials.Types of Metal Plates. Here are some specific types of metal plates, along with their features and applications: Mild Steel Plates. These plates consist of low-carbon steel, making them malleable and easy to weld. Commonly, they are applied in construction, fabrication, and manufacturing due to their strength and affordability. Checkered Plates

2. Sheet Metalworking Defined Cutting and forming operations performed on relatively thin sheets of metal Thickness of sheet metal = 0.4 mm (1/64 in) to 6 mm (1/4 in) Thickness of plate stock > 6 mm Operations usually performed as cold working ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e Steel plate metal is the thickest designation. Any sheet metal thicker than 6mm is known as plate metal. Steel plate is durable but heavy. It’s used in applications where strength is more important than saving weight. Applications. Metal foil, sheet metal, and plate metal are designated by their thickness, not by their chemical and physical . A perforated metal sheet has a structural strength that is superior to many building materials. According to the Industrial Perforators Association, round holes arranged in a standard 60 degree triangular pattern ranging from .020” to .75” account for more than 50% of perforated metal production. This standard 60-degree staggered pattern is .

Marlin Steel Wire Products . 2648 Merchant Drive Baltimore, MD 21230-3307. Phone (410) 644-7456 Fax (410) 630-7797Uniformity Our American-made metal switch plates have been produced for over 50 years.They won't change color over time so you can be confident any later additions will match. Most cheap plastic plates discolor over time, so even buying the same brand and style will not guarantee a . Learn more about us by visiting one of our websites below. Joseph Smith & Sons, Capitol Heights, MD www.josephsmithsons.comDenton Scrap, Denton, MD www.de.

When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. . Even when the non-ferrous metal plate and the steel plate are the same Ga., the thickness is actually different. You can find the gauge to mm / inch conversion for sheet metal by the chart below. Sheet Metal Gauge to .

plates sheets and strip

plate vs sheet strip

DeeZee Specialty Series Wheel Well Tool Box with Drawers - Steel - 1.9 Cu Ft - Black

sheet metal vs plate metal|steel sheet vs plate