2024 sheet metal bend radius RECOMMENDED MINIMUM BEND RADII FOR 90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in . Typical metals used for roofing include steel, aluminum, copper, and zinc. The cost of metal roofing also varies on the specific material you use. Steel is the most popular and typically least expensive metal roofing option. It’s known for its strength and durability, often lasting for 30–50 years or more.

0 · sheet metal bend radius guide

1 · sheet metal bend radius formula

2 · sheet metal bend radius calculator

3 · sheet metal bend deduction chart

4 · maximum thickness sheet metal bending

5 · how to calculate bend radius

6 · bend radius sheet metal chart

7 · bend radius definition sheet metal

This article provides a comprehensive look at the types of CNC machine tool coolants available, their uses across industries, the importance of selecting the right coolant, .

RECOMMENDED MINIMUM BEND RADII FOR 90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in .

Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material .

sheet metal bend radius guide

sheet metal bend radius formula

The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for .For this layout example, use the minimum radius chart in Figure 2 to choose the correct bend radius for the alloy, temper, and the metal thickness. For 0.040, 2024-T3 the minimum . The bend radii listed are standard minimum for manufacturing for aerospace and space applications. Commercial sheet metal radius are created with less concern for stresses . Use Xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects

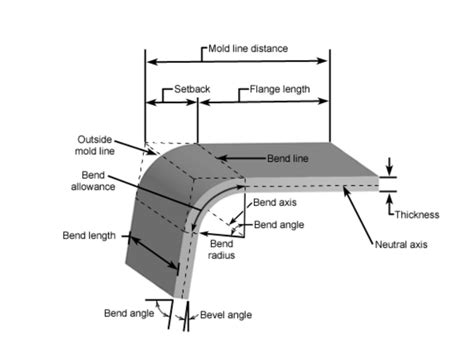

The bend tolerance is basically the allowable radius you can form aircraft sheet before it starts to crack. In most cases if you are unable to form in the original temper you will have to . The bend radius refers to the inner radius of curvature in a bent metal part, where ‘t’ represents the material thickness. This parameter is crucial in sheet metal fabrication and structural design. The default bend radius in SOLIDWORKS is 0.100”, a specification that requires specialty tooling to achieve. We recommend changing the bend radius to 0.030”, the industry standard for sheet metal with a thickness of up to .RECOMMENDED MINIMUM BEND RADII FOR 90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in a standard press brake with air bend dies. Other types of bending operations may require larger radii or permit smaller radii.

Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material thicknesses up to 0.125" (⅛") and increase the bend radius for thicker materials.Consider what minimum bend size you require (Only consider lines that meet your minimum bend requirement). You may choose any bend radius on this line(s). If you have multiple options, optimize your choice.The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation, the radius can be near zero for thin sheet metal.

For this layout example, use the minimum radius chart in Figure 2 to choose the correct bend radius for the alloy, temper, and the metal thickness. For 0.040, 2024-T3 the minimum allowable radius is 0.16-inch or 5⁄32-inch.The bend radii listed are standard minimum for manufacturing for aerospace and space applications. Commercial sheet metal radius are created with less concern for stresses created during forming and radii can approach zero (sharp internal corner) for . Use Xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects

The bend tolerance is basically the allowable radius you can form aircraft sheet before it starts to crack. In most cases if you are unable to form in the original temper you will have to anneal to the O temper, form your parts then re-heat treat. The bend radius refers to the inner radius of curvature in a bent metal part, where ‘t’ represents the material thickness. This parameter is crucial in sheet metal fabrication and structural design. The default bend radius in SOLIDWORKS is 0.100”, a specification that requires specialty tooling to achieve. We recommend changing the bend radius to 0.030”, the industry standard for sheet metal with a thickness of up to 0.125”. For thicker metals, we can help you determine the appropriate bend radius. To set a bend radius in SOLIDWORKS:RECOMMENDED MINIMUM BEND RADII FOR 90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in a standard press brake with air bend dies. Other types of bending operations may require larger radii or permit smaller radii.

sheet metal bend radius calculator

Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material thicknesses up to 0.125" (⅛") and increase the bend radius for thicker materials.Consider what minimum bend size you require (Only consider lines that meet your minimum bend requirement). You may choose any bend radius on this line(s). If you have multiple options, optimize your choice.The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation, the radius can be near zero for thin sheet metal.For this layout example, use the minimum radius chart in Figure 2 to choose the correct bend radius for the alloy, temper, and the metal thickness. For 0.040, 2024-T3 the minimum allowable radius is 0.16-inch or 5⁄32-inch.

The bend radii listed are standard minimum for manufacturing for aerospace and space applications. Commercial sheet metal radius are created with less concern for stresses created during forming and radii can approach zero (sharp internal corner) for . Use Xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects

The bend tolerance is basically the allowable radius you can form aircraft sheet before it starts to crack. In most cases if you are unable to form in the original temper you will have to anneal to the O temper, form your parts then re-heat treat.

The bend radius refers to the inner radius of curvature in a bent metal part, where ‘t’ represents the material thickness. This parameter is crucial in sheet metal fabrication and structural design.

sheet metal bend deduction chart

maximum thickness sheet metal bending

how to calculate bend radius

bend radius sheet metal chart

With its unique design, the corrugated metal sheet offers a balance of strength, functionality, and aesthetic appeal. In this comprehensive guide, we will explore the world of corrugated metal sheets, delving into the different types, materials, and their numerous applications.

2024 sheet metal bend radius|maximum thickness sheet metal bending