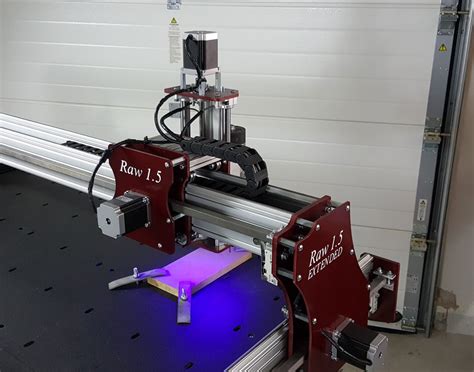

cnc machine belt drive What are the advantages/disadvantages of belts versus direct drive systems, especially for long travels like an 8' on CNC routers? It seems that it would be relatively easy . 8 Pcs 4 Hole U-Shape Bracket for 3/4" Panels, Stamped 304 Stainless Steel Partition U Bracket, Installation Fasteners, Thickness 2.8mm

0 · rack and pinion for cnc

1 · rack and pinion drive cnc

2 · machine rack and pinion

3 · helical rack and pinion cnc

4 · cnc router rack and pinion

5 · cnc belt vs lead screw

6 · cnc belt drive kit

7 · belt driven cnc machine

The specific UL standards that apply to electrical enclosures are UL50 and UL50E, which are approximately equivalent to the NEMA 250 standards discussed above. The same numbering scheme is used for UL type ratings as NEMA or CSA standards, and all three are generally equivalent to each other with some minor differences.

Compare rack and pinion, belt drive, and ballscrew systems for CNC machining. Learn about the pros and cons of each option for your . Both the 4040 Reno and 4040-PRO are fantastic machines, but the key difference lies in how they move the cutting tool: belts versus lead screws. Understanding these two drive .The belt drive seems like it would be easier to set up overall. I wonder what precision each method can allow and what they are best suited for. Also, is . What are the advantages/disadvantages of belts versus direct drive systems, especially for long travels like an 8' on CNC routers? It seems that it would be relatively easy .

rack and pinion for cnc

rack and pinion drive cnc

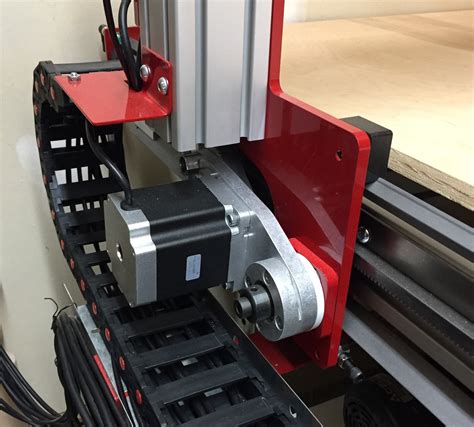

I'm assuming you mean a timing belt set-up which directly drives the axis via a pulley. PROS: - Very efficient - Can have long runs with minimal impact on design (no whip) - . Research notes on a cnc belt drive milling spindle for small hobby CNC mills. Lots of good info on spindle bearings too. 1) Central belt between two sprockets, with a belt mated plate attaching belt to the gantry along it's line of travel, probably under the gantry on the bottom of the machine. 2) Two .

Belts should have no play, but are usually directly driven. Leadscrews are mechanically set up to provide a gear reduction, so will increase positioning resolution. Rack and pinion also have a .

Everman belt drive system The Everman belt drive system (aka “ Positioner utilizing engaged toothed gear belts, one static and one dynamic”) is a simple modification that reduces the stretch or flex of a timing belt over long . Compare rack and pinion, belt drive, and ballscrew systems for CNC machining. Learn about the pros and cons of each option for your application. Explore now!There is a big difference between taking a simple length of belt and measuring the stretch under load, compared to the same length of belt in a CNC machine when preloaded. Both the preload in the belt and the flex in the teeth as they are meshed into the pulley, will act to counteract externally applied force.

fresa diamante cnc

machine rack and pinion

fresca mirror medicine cabinet top mounting bracket

Both the 4040 Reno and 4040-PRO are fantastic machines, but the key difference lies in how they move the cutting tool: belts versus lead screws. Understanding these two drive systems will help you get the most out of your new desktop CNC machine. The belt drive seems like it would be easier to set up overall. I wonder what precision each method can allow and what they are best suited for. Also, is using a double belt any good? What are the advantages/disadvantages of belts versus direct drive systems, especially for long travels like an 8' on CNC routers? It seems that it would be relatively easy to calculate the innaccuracies of a direct driven system, but not so easy for a belt-driven one. I'm assuming you mean a timing belt set-up which directly drives the axis via a pulley. PROS: - Very efficient - Can have long runs with minimal impact on design (no whip) - Very fast rapids achievable (useful with laser cutters, plasma, etc. .

Research notes on a cnc belt drive milling spindle for small hobby CNC mills. Lots of good info on spindle bearings too.

1) Central belt between two sprockets, with a belt mated plate attaching belt to the gantry along it's line of travel, probably under the gantry on the bottom of the machine. 2) Two belts between two sprockets each with belt fixed to gantry along both sides. Belts should have no play, but are usually directly driven. Leadscrews are mechanically set up to provide a gear reduction, so will increase positioning resolution. Rack and pinion also have a gear reduction. Belts are faster due to being more directly driven by the motor. Everman belt drive system The Everman belt drive system (aka “ Positioner utilizing engaged toothed gear belts, one static and one dynamic”) is a simple modification that reduces the stretch or flex of a timing belt over long drive systems.

Compare rack and pinion, belt drive, and ballscrew systems for CNC machining. Learn about the pros and cons of each option for your application. Explore now!There is a big difference between taking a simple length of belt and measuring the stretch under load, compared to the same length of belt in a CNC machine when preloaded. Both the preload in the belt and the flex in the teeth as they are meshed into the pulley, will act to counteract externally applied force. Both the 4040 Reno and 4040-PRO are fantastic machines, but the key difference lies in how they move the cutting tool: belts versus lead screws. Understanding these two drive systems will help you get the most out of your new desktop CNC machine.

helical rack and pinion cnc

The belt drive seems like it would be easier to set up overall. I wonder what precision each method can allow and what they are best suited for. Also, is using a double belt any good?

What are the advantages/disadvantages of belts versus direct drive systems, especially for long travels like an 8' on CNC routers? It seems that it would be relatively easy to calculate the innaccuracies of a direct driven system, but not so easy for a belt-driven one.

I'm assuming you mean a timing belt set-up which directly drives the axis via a pulley. PROS: - Very efficient - Can have long runs with minimal impact on design (no whip) - Very fast rapids achievable (useful with laser cutters, plasma, etc. .

Research notes on a cnc belt drive milling spindle for small hobby CNC mills. Lots of good info on spindle bearings too. 1) Central belt between two sprockets, with a belt mated plate attaching belt to the gantry along it's line of travel, probably under the gantry on the bottom of the machine. 2) Two belts between two sprockets each with belt fixed to gantry along both sides. Belts should have no play, but are usually directly driven. Leadscrews are mechanically set up to provide a gear reduction, so will increase positioning resolution. Rack and pinion also have a gear reduction. Belts are faster due to being more directly driven by the motor.

frese speciali cnc

Ultra Pro - Satin Tower 100+ Card Deck Box (Glitter Black) - Protect Your Gaming Cards, Sports Cards or Collectible Cards In Stylish Glitter Deck Box, Perfect for Safe Traveling

cnc machine belt drive|cnc belt drive kit