aerospace 5 axis cnc machining Why 5-Axis Machining for Aerospace? One of the biggest reasons 5-axis machining is so prevalent in the world of aerospace is machine setup. The parts often have complex geometries that don’t easily lend to 3- or 4-axis . There are various materials that can be used to produce sheet metal: Aluminum: Lightweight and resistant to corrosion, aluminum is commonly applied in the aerospace and automotive industries. Steel: Mild steel is a popular choice .

0 · what is 5 axis milling

1 · what does 5 axis mean

2 · small 5 axis cnc mill

3 · benefits of 5 axis machining

4 · 5 axis trunnion machining

5 · 5 axis machining explained

6 · 5 axis machining basics

7 · 5 axis cnc explained

Depending on how you count, there are as many as 150 (or more) types of stainless steel, each falling into a handful of general categories: Below, we’ll review a handful of the specific types (or grades) of stainless steel that readers are most likely to encounter in day to day life.

Why 5-Axis Machining for Aerospace? One of the biggest reasons 5-axis machining is so prevalent in the world of aerospace is machine setup. The parts often have complex geometries that don’t easily lend to 3- or 4-axis .With decades of experience in the aerospace industry, TARUS 5-axis CNC machines are in widespread use by manufacturers of aerospace tooling including layup molds, machining fixtures, assembly jigs and friction stir welding fixtures. With smaller work envelopes, 5-axis machines that aren’t made for one-off production are usually tool-room style machines typically used in . Discover the benefits of 5-axis CNC machining in precision manufacturing. From enhanced accuracy to faster production and optimized tooling, learn how 5-axis technology is .

what is 5 axis milling

what does 5 axis mean

Precision CNC machining is pivotal in making high-quality aerospace components. The aerospace sector has strict safety controls and high production standards for CNC machining aerospace parts. These parts require . 5-axis CNC machining is transforming aerospace manufacturing at Roberson Machine Company, offering unrivaled precision, efficiency, and flexibility. Some of the ways . 5-axis CNC milling machines are widely used in aerospace manufacturing due to their ability to move a tool or part along five different axes simultaneously. This capability allows for the creation of complex geometries .

The Takumi U800 is a 5-axis, high-speed, CNC machining center that produces outstanding surface finish and is great for aerospace and automotive industries.

Five-axis simultaneous machining offers a great solution for producing complex machined parts and meeting aerospace, defense, and space requirements. There are several ways to define and implement 5-axis machining. 5-axis machining is widely used in industries such as aerospace, automotive, medical, and die/mold manufacturing, where precision and complex shapes are required. . Why 5-Axis Machining for Aerospace? One of the biggest reasons 5-axis machining is so prevalent in the world of aerospace is machine setup. The parts often have complex geometries that don’t easily lend to 3- or 4-axis operations.

image of white metal box box file mobile pedestal

small 5 axis cnc mill

image of power distribution box on a 97 ford taurus

With decades of experience in the aerospace industry, TARUS 5-axis CNC machines are in widespread use by manufacturers of aerospace tooling including layup molds, machining fixtures, assembly jigs and friction stir welding fixtures. With smaller work envelopes, 5-axis machines that aren’t made for one-off production are usually tool-room style machines typically used in aerospace organizations’ research and development (R&D) centers, including Lockheed Martin’s SkunkWorks or Boeing’s Phantom Works. Discover the benefits of 5-axis CNC machining in precision manufacturing. From enhanced accuracy to faster production and optimized tooling, learn how 5-axis technology is transforming aerospace, medical, and automotive industries with complex geometries and high-quality finishes. Explore why investing in 5-axis machines could elevate your manufacturing . Precision CNC machining is pivotal in making high-quality aerospace components. The aerospace sector has strict safety controls and high production standards for CNC machining aerospace parts. These parts require the tightest and highest tolerances, dimensions, and performance for every component.

5-axis CNC machining is transforming aerospace manufacturing at Roberson Machine Company, offering unrivaled precision, efficiency, and flexibility. Some of the ways our solutions can help your company include:

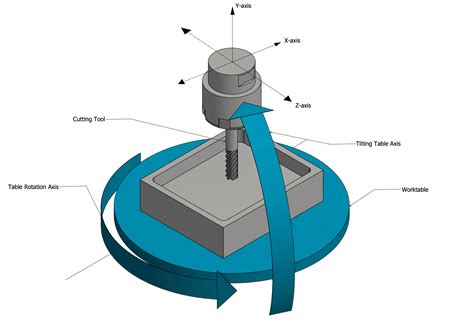

5-axis CNC milling machines are widely used in aerospace manufacturing due to their ability to move a tool or part along five different axes simultaneously. This capability allows for the creation of complex geometries and intricate parts in a single setup, reducing the need for multiple fixtures and improving overall efficiency.The Takumi U800 is a 5-axis, high-speed, CNC machining center that produces outstanding surface finish and is great for aerospace and automotive industries.Five-axis simultaneous machining offers a great solution for producing complex machined parts and meeting aerospace, defense, and space requirements. There are several ways to define and implement 5-axis machining.

5-axis machining is widely used in industries such as aerospace, automotive, medical, and die/mold manufacturing, where precision and complex shapes are required. However, it also comes with increased complexity in programming, setup, and tool path optimization compared to 3-axis machining. Why 5-Axis Machining for Aerospace? One of the biggest reasons 5-axis machining is so prevalent in the world of aerospace is machine setup. The parts often have complex geometries that don’t easily lend to 3- or 4-axis operations.With decades of experience in the aerospace industry, TARUS 5-axis CNC machines are in widespread use by manufacturers of aerospace tooling including layup molds, machining fixtures, assembly jigs and friction stir welding fixtures.

benefits of 5 axis machining

With smaller work envelopes, 5-axis machines that aren’t made for one-off production are usually tool-room style machines typically used in aerospace organizations’ research and development (R&D) centers, including Lockheed Martin’s SkunkWorks or Boeing’s Phantom Works.

Discover the benefits of 5-axis CNC machining in precision manufacturing. From enhanced accuracy to faster production and optimized tooling, learn how 5-axis technology is transforming aerospace, medical, and automotive industries with complex geometries and high-quality finishes. Explore why investing in 5-axis machines could elevate your manufacturing .

Precision CNC machining is pivotal in making high-quality aerospace components. The aerospace sector has strict safety controls and high production standards for CNC machining aerospace parts. These parts require the tightest and highest tolerances, dimensions, and performance for every component.

5-axis CNC machining is transforming aerospace manufacturing at Roberson Machine Company, offering unrivaled precision, efficiency, and flexibility. Some of the ways our solutions can help your company include: 5-axis CNC milling machines are widely used in aerospace manufacturing due to their ability to move a tool or part along five different axes simultaneously. This capability allows for the creation of complex geometries and intricate parts in a single setup, reducing the need for multiple fixtures and improving overall efficiency.The Takumi U800 is a 5-axis, high-speed, CNC machining center that produces outstanding surface finish and is great for aerospace and automotive industries.

Five-axis simultaneous machining offers a great solution for producing complex machined parts and meeting aerospace, defense, and space requirements. There are several ways to define and implement 5-axis machining.

in pool light deck junction box j-box

Whether you’re starting new construction or adding to existing wiring, understanding the different types of electrical boxes helps for a safe installation. We’ll break down the categories of electrical boxes and explain their uses.

aerospace 5 axis cnc machining|5 axis machining explained