cnc turning machine axis If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping. FS Device Box, 1-Gang, FS Type, Malleable Iron Ridge Top, Cast Box. Hub Size 3/4 Inch. Box Depth 2 Inch Includes: Internal Ground Screw. For use with Threaded Rigid Metal Conduit

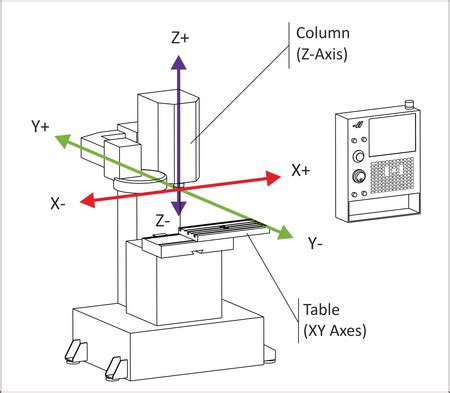

0 · milling machine axis diagram

1 · cnc mill axis diagram

2 · cnc machine axis locations diagram

3 · cnc machine axis direction

4 · cnc lathe axis explained

5 · cnc lathe axis diagram

6 · cnc axis chart

7 · axis identification in cnc machine

Arlington's non-metallic enclosure boxes now MEET NEMA 3R requirements for outdoor use. They're the perfect solution to protecting and securing power backups, security devices and other valuable equipment indoors or outside.

We will discuss the role of the Y-axis in various CNC machining operations, including drilling, contouring, and pocketing. Furthermore, we will highlight the factors that influence the . The CNC Turning Center is one of the critical devices in today’s machining environment, as it allows the manufacture of complex parts with high levels of accuracy and .If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping. Turning is a subtractive machining process that uses a cutting tool to remove material for creating cylindrical parts. The tool itself moves along the axis of the machined part while the part is rotating, creating a helical toolpath.

There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool .

Whereas a CNC Machining Center performs a rotating spindle operation, a CNC Turning Center performs a turning type operation. What are the Machine Axes in a CNC Turning Center? There are up to five axes that a CNC . A CNC (Computer Numerical Control) lathe is a sophisticated machine tool that utilizes computer-programmed instructions to perform high-precision turning operations around various axes. The number and .

3-Axis vs. 5-Axis: Pros and Cons. The main difference between these two types of CNC machines is the number of ways they can move their tool: one has three, and one has five. This seemingly small factor, however, makes .Find here CNC Turning Machine, CNC Turning Machinery manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying CNC Turning Machine, CNC Turning Machinery, .With over 150 years of experience in turning, DMG MORI offers comprehensive technological expertise, reflected in around 20 different series of CNC lathes: As a machine tool manufacturer, we cover a wide range of applications, from .Hyundai Wia has a complete line of linear and box way multi-axis CNC turning Centers. Their line-up boasts the robust HD and L series of multi-axis lathes ranging from 8" chuck models to the massive KL8000LY with a 32" chuck. .

milling machine axis diagram

This machine is also incredibly versatile – as well as turning, it offers milling, Y-axis and second spindle capability. This is thanks to the C-axis indexing in 0.001-degree increments, along with rotary tools mounted on the turret. . CNC lathe machines are used in a variety of industries such as aerospace, automotive, medicine, and .CNC turning machine also can process some complex rotary surface, such as hyperboloid. Multiple axis can be added according to the demand: c axis lathe, 3 axis lathe, 2 axis lathe, 5 axis CNC lathe, 4 axis CNC lathe. It describes turning as a machining process using a lathe where the tool moves parallel to the workpiece axis to remove material. CNC lathes are replacing older lathes. Milling involves using rotating cutting tools to produce flat and helical surfaces. Machining centers are classified as vertical, horizontal, or universal depending on the .

A CNC (Computer Numerical Control) lathe is a sophisticated machine tool that utilizes computer-programmed instructions to perform high-precision turning operations around various axes. The number and configuration of axes are crucial components of a CNC lathe’s capabilities, with different combinations available for various machining .CNC turning machine. B400 . Diameter: 315 mm Spindle speed: 4,000 rpm . BC3751-H is a high-performance and multifunctional turning center. Machine tool has C-axis and milling functions, which can finish most or all of the processing of complex parts in .The numbers of axes determine what type of movement a CNC machine can conduct. Axes Movements. X axis – left to right; Y axis – front to back; Z axis – up and down; A axis – 180° rotation around the X axis; B axis – 180° rotation around the Y axis; C axis - 180° rotation around the Z axis; Types of CNC Machines. 3 Axis – X, Y . CNC mills are usually 3 axis machines and lathes are 2 axis. Both types of machines can have more axes but let’s keep things simple. Less axes are usually easier to understand so let’s start with 2 axis coordinates. With two .

Due to the ability of a 7-axis CNC machine to mill while turning the part within the frame, you can produce extraordinarily complex shapes and features. A 7-axis CNC machine is especially useful in the aerospace and military industries. 9-Axis CNC Machining. The 9-axis CNC combines a 4-axis lathe and 5-axis milling machine.

Our LU35II CNC turning center is the latest evolution of our large 4-axis turning centers. Two turrets offer dramatic improvements in process flexibility and cycle time when compared to 2-axis machines.

CNC systems, multi-tasking machines, CNC turning centers, horizontal machining centers, vertical machining centers, CNC laser machines, FMS (Flexible Manufacturing System), and CAD/CAM software system. . It not only has the turning, milling and 5-axis machining capabilities of composite machining equipment, but also integrates the .Utilizing a unique 3-axis movement of the sub-spindle, machine physical size is minimized by the sub-spindle’s ability to move in the X-axis above and below the center line out of the way of the B-axis milling spindle. This high production CNC turning center is cast from Meehanite iron.

flower box brackets on metal railing

Adding a third axis, the Y-axis, allows for more complex machining tasks. 3-axis CNC turning centers can perform operations that are perpendicular to the X and Z axes. Y-axis: Enables off-center milling and drilling. These machines often use ball screw actuators for precise movements and can handle more complex parts. The tools are arranged on . The Z-axis allows for turning operations such as taper turning, threading, and grooving. By adjusting the Z-axis, the cutting tool can move closer or farther from the top surface of the workpiece, enabling precise control over . A CNC turning center is a type of computer-controlled machine tool that is used to perform various machining operations on metal workpieces. The operations that can be performed on a CNC turning center include .

flower box metal

What is CNC Turning? CNC turning, also known as computer numerical control turning, is a machining process that utilizes computerized controls to rotate a workpiece while cutting tools remove material to achieve the desired shape.It is a highly precise and efficient method of manufacturing components with complex geometries, such as cylinders, cones, and .FNL-220Y/ LY/ LSY/ LS/ LSMC CNC Turn Mill Machine. FNL-220 series CNC Turn Mill Center Machine is designed with dual 30-degree slant bed and roller linear ways structure that delivers low-friction, high-rigidity and high-loading capacity, it .Cutter Innovations is a Colorado-based AS9100 certified machine shop & manufacturing company specializing in the precision machining of exotic metals and product development. At our state-of-the-art precision CNC machine shop, our talented staff has over 50 combined years of experience and is capable of delivering tight tolerances in exotic materials, on time, and to your .

Product Description. The LL20T L5 turning center is designed for high-efficiency turning to meet market demands. It has 8’’ chuck, turning diameter of up to 320 mm and a turning length of up to 500 mm This machine offers versatility for a wide range of turning applications for industries like pumps, valves, oil and gas, industrial machinery, general engineering, etc.The TMA8F is a 6-Axis Turn/Mill equipped with a 60 tool magazine and the ability to perform full 5-Axis simultaneous machining to machine complex parts complete in a compact, flexible machine tool. You can take the most complex part and perform a full range of operations: CNC milling, drilling, tapping, compound angle work, turning, boring, and .Study with Quizlet and memorize flashcards containing terms like Name the two primary machine axes on most CNC turning machines., Explain the difference between a turning center and a CNC lathe., List the three common types of live toolholders. and more.Turning was traditionally done by hand, but nowadays it is mostly carried out by Computer Numerical Controlled (CNC) machines or lathes which include 4-axis turning machines. CNC machines produce parts that are cut precisely to match the design by entering a code that controls the tool path, the speed of the spindle and depth of cut.

The NTK CUTTING TOOLS official website introduces products of CNC automatic lathe cutting tools, heat-resistant alloy machining cutting tools, high-hardness material machining cutting tools, and cast iron ductile cast iron machining cutting tools. We will provide permanent stability to the manufacturing site and new value that will lead to the next generation of manufacturing.This machine is our standard machine with the smallest footprint. The MTC 250 is based on a T-shaped natural granite bed. X- and Z-axis slides, as well as the housing of the main spindle are made of granite too. Both slides and the optional B-axis use hydrostatic (oil) bearings. The main spindle features an air bearing and is mounted to the X .

cnc mill axis diagram

CNC lathes come in multiple configurations and can match any requirement, from pure OD and ID turning to combinations of turning, off-axis drilling, and even milling all in one machine. This results in the capability to run ‘done-in-one’ operations with ease.

cnc machine axis locations diagram

$17.98

cnc turning machine axis|axis identification in cnc machine