cnc machine for drill shelving holes Drilling shelf pin holes, especially using the 32mm system, is a straightforward process that can be done manually with a drill and jig or more efficiently with a CNC router. The choice between these methods depends on the scale of . $899.00

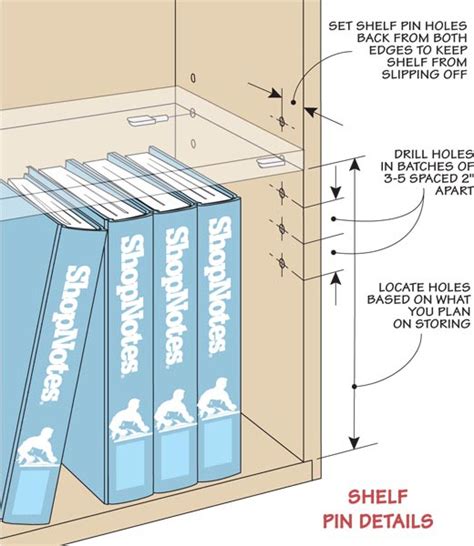

0 · shelf pin holes diagram

1 · shelf pin holes

2 · onefinity cabinet drilling holes

3 · drilling shelf pin holes

$51.64

shelf pin holes diagram

sheet metal fabrication in vancouver

Drilling gables with the Onefinity CNC is a game changer. It works great! You can drill whatever pattern suits your needs best. By setting up so shelves can be mounted verticaly at the front, you can drill dowel holes. The .Subscribe chanel: https://goo.gl/bghvVP______Reference machine list______👉 WOOD BARKING MACHINE: https://www.youtube.com/watch?v=z1zqcf4q_10👉 Full Optione . Drilling shelf pin holes, especially using the 32mm system, is a straightforward process that can be done manually with a drill and jig or more efficiently with a CNC router. The choice between these methods depends on the scale of . Drilling gables with the Onefinity CNC is a game changer. It works great! You can drill whatever pattern suits your needs best. By setting up so shelves can be mounted verticaly at the front, you can drill dowel holes. The matchup between the gables and shelves is perfect.

Subscribe chanel: https://goo.gl/bghvVP______Reference machine list______👉 WOOD BARKING MACHINE: https://www.youtube.com/watch?v=z1zqcf4q_10👉 Full Optione .

CNC drilling machine is a precise and efficient processing technology that can automatically drill holes in fixed workpieces (wood, metal, plastic or composite materials). CNC drilling machine uses computer programs to control the movement of the drill with high precision. Most drill bits aren’t rated for even the slowest speed on the Makita, but some are: Drills – IDC Woodcraft. One option is to use a downcut bit of a smaller diameter than the hole, and use a boring toolpath the helix into the holes.This video teaches you how to drill holes on a CNC router using peck drilling and spiral drilling. Plunge drilling on a CNC router is not recommended unless .Blue Elephant provides a range of side drilling machine, including single heads, double heads, double heads with saws, and a six-sided drilling centers. These machines are good at drilling, grooving, and punching vertical and side holes, as well as crafting grooves on wooden boards.

I bought a few brad point 5mm drill bits with a 1/4 shank for shelf pin holes in ply and melamine. I drill them in one go, maybe 11mm deep. I don't get tearout or chipping. rpm 12K, z feed 150ipm.

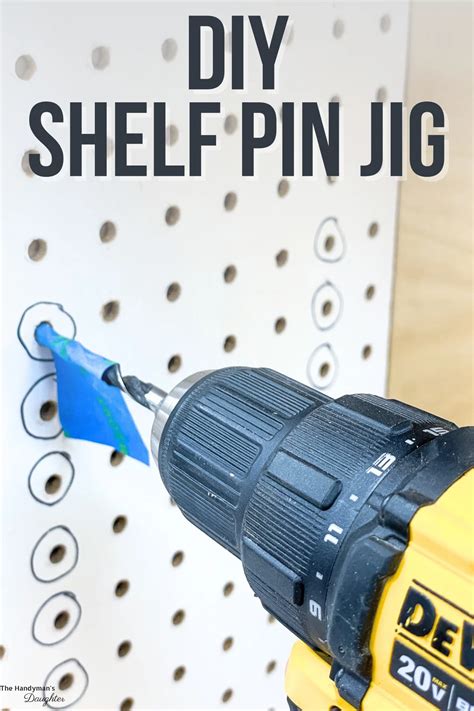

I wanted adjustable shelving, and was dreading the idea of drilling shelf bracket holes manually, when it occurred to me that the PowerRoute would have no problem cranking this out with accuracy well above what I could do with a custom jig. It took about 3 minutes each, for 8 different shelf 'sides' to create the holes.Before we got a CNC we did all of our Rafix drilling on the Ritter. Set a flip stop so that you can use the end bits on both heads to drill for the fittings. Drill all of your verticals, then switch to Rafix. Drilling shelf pin holes, especially using the 32mm system, is a straightforward process that can be done manually with a drill and jig or more efficiently with a CNC router. The choice between these methods depends on the scale of .

shelf pin holes

Drilling gables with the Onefinity CNC is a game changer. It works great! You can drill whatever pattern suits your needs best. By setting up so shelves can be mounted verticaly at the front, you can drill dowel holes. The matchup between the gables and shelves is perfect.Subscribe chanel: https://goo.gl/bghvVP______Reference machine list______👉 WOOD BARKING MACHINE: https://www.youtube.com/watch?v=z1zqcf4q_10👉 Full Optione . CNC drilling machine is a precise and efficient processing technology that can automatically drill holes in fixed workpieces (wood, metal, plastic or composite materials). CNC drilling machine uses computer programs to control the movement of the drill with high precision. Most drill bits aren’t rated for even the slowest speed on the Makita, but some are: Drills – IDC Woodcraft. One option is to use a downcut bit of a smaller diameter than the hole, and use a boring toolpath the helix into the holes.

This video teaches you how to drill holes on a CNC router using peck drilling and spiral drilling. Plunge drilling on a CNC router is not recommended unless .

Blue Elephant provides a range of side drilling machine, including single heads, double heads, double heads with saws, and a six-sided drilling centers. These machines are good at drilling, grooving, and punching vertical and side holes, as well as crafting grooves on wooden boards. I bought a few brad point 5mm drill bits with a 1/4 shank for shelf pin holes in ply and melamine. I drill them in one go, maybe 11mm deep. I don't get tearout or chipping. rpm 12K, z feed 150ipm.

I wanted adjustable shelving, and was dreading the idea of drilling shelf bracket holes manually, when it occurred to me that the PowerRoute would have no problem cranking this out with accuracy well above what I could do with a custom jig. It took about 3 minutes each, for 8 different shelf 'sides' to create the holes.

Here are some options, advantages, disadvantages, and project examples for white metal roofing. White Color Options Available From Sheffield Metals. Before we get into the benefits and drawbacks of choosing white for your metal roof or wall system, let’s take a look at the variety of white color options available at Sheffield Metals.

cnc machine for drill shelving holes|shelf pin holes