how small can a cnc machine cut Let’s do a quick recap of all the factors that go into how deep you can cut with your CNC Router. Machine size and gantry height are some of the most important measurements needed before determining cutting capabilities. $59.98

0 · how deep can a cnc cut

1 · depth of cnc router cutting

Turck JBBS-57-E812 Junction Box,DeviceNet Hub,8 M12 Connector Ports, 1Male and 1Female Minifastport Mfr. Part #: JBBS-57-E812 / RS Stock #: 70035464

how deep can a cnc cut

Though, how deep a CNC router cuts depends on many factors, including the Z-axis, the flute length, vibrations, tool diameter, material, spindle power, feed rate (or chip load), and radial depth of cut. I’ll explain them all in .The size of the cut that a CNC machine can achieve is influenced by several factors, including the machine's design, the cutting tool's dimensions, the material being cut, and the limitations of .

depth of cnc router cutting

For example, CNC machines can carve wood, cut metals, and even engrave surfaces—all controlled through computer software. What Even Is a CNC Machine? . Onefinity CNC .

The wooden frame has to be about ½” thick that means I have to find a very tiny end mill about 1mm or 0.5mm but with a long reach maybe something like ¼” so it can cut it half .

Let’s do a quick recap of all the factors that go into how deep you can cut with your CNC Router. Machine size and gantry height are some of the most important measurements needed before determining cutting capabilities.

Just curious if anyone does a depth of cut deeper than the diameter of the bit. Yes, but not with a 1/8" bit. Why don't you just cut faster. You can probably cut close to 300ipm with .

So cutting completely through 1-1⁄2"-thick material requires Z-axis travel of 3-1⁄4" or more. And if a machine doesn't come with a spoilboard, remember that adding one reduces the stated Z-axis travel by that board's .These compact, versatile machines are designed for precision metal cutting and are a game-changer for anyone needing a reliable mini CNC mill. Investing in a small CNC milling machine is a wise decision that can significantly enhance .

-Credit: TAIG. If you’re looking for a benchtop CNC Mill that can machine hard metals and is affordable to a hobbyist, then this guide will walk you through all the best options .

,799.99,487.50,999.99,399.99

,593.13,875.46,999.99

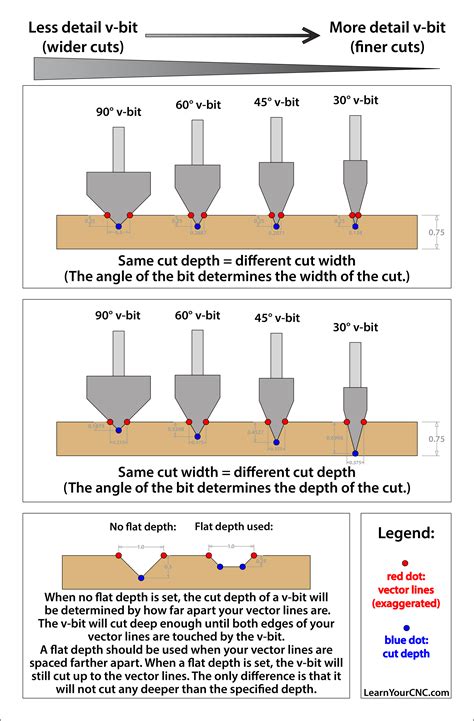

Whether you are buying a CNC machine under ,000 or ,000, it doesn’t matter; you need to make the right decision for yourself or your business. How to Buy a CNC Mill – The Smart Way. Having your CNC .I've been looking into laser cutters for cutting acrylic but I came to realize a desktop milling machine might be a better alternative. I'm very very new to this Looking to cut acrylic sheets maybe 5-7mm thickness. Something with a decent work surface, I've seen smaller machines on ebay, but it looks like the surface area is only maybe 7 by 7 .Looking for recommendations for a desktop CNC mill to cut 0.1 - 1.0mm sheet brass or aluminum to make various watch parts such as dials and hands. Some precision is required due to the small nature of the parts (I'd be making stuff like 28mm circles with 5x2mm rectangle cutouts, or like, a small 4mmx4mm airplane shape to stick onto a seconds hand). Model of CNC Machine: CRP4896 Location: San Francisco Bay Area. How do I cut a 45 degree angle on a flat plane? . A small 90 degree V-Bit could cut the 45 degree edge if set up as a V-Carve "area". Then again if you have a miter box and hand saw, or compound miter saw, or table saw with miter gauge, or radial arm saw you could cut your 45 .

In this article, we’ll discuss two main types of machines: CNC routers (which can cut soft metals like aluminum) and CNC metal mills (designed to handle harder metals like steel, stainless steel, brass, titanium, magnesium, and more.) I’ll step you through my hands-on experience with each machine (comparing key features like power, work area, and ease of .Even proper machine shops tend to avoid Carbon fiber. And when they do cut it, they ussualy submerge the whole thing into water(?) to avoid the flying dust of doom. I did it once but i live in a farm an just took the machine outside and then cleaned it with a damp cloth.

1. Carbide 3D Shapeoko 4: Best Wood CNC Carving Machine for DIYers; 2. BobsCNC Evo 4: Best CNC Wood Router for the Money; 3. Axiom Iconic Series: User-Friendly Wood Carving Machine; 4. BobsCNC KL744: Best Large CNC Machine for Woodworking; 5. ZMorph Fab: Most Versatile Wood CNC MachineI have seen a few small desktop CNC machines on here and YouTube etc. I built a large CNC machine a couple of years ago and I have been trying to stiffen it up but it’s proving nearly impossible. I’d like to just buy a small machine at this point that is capable of cutting aluminium with a reasonably high degree of accuracy. Can some please look at my attached files and tell me if it’s possible to do such a delicate and intricate cut on the Taig or similar small CNC machine. The wooden frame has to be about ½” thick that means I have to find a very tiny end mill about 1mm or 0.5mm but with a long reach maybe something like ¼” so it can cut it half way and .Laser engravers (certainly the ones available to mere mortals) won’t engrave metal in the way you think - it won’t give a nice, deep, 3D surface, but they can mark it . For small size, precise work like you’re describing, you probably want to look for a desktop CNC milking machine, or (if you can find one!) a dental milking machine would .

e & j metal fabricators limited

When I tried cutting 2" x 2" square when I built the machine it cut it square and to size. Similar Threads: Need Help!-Chinese Laser not cutting to correct scale; News Large-Scale Waterjet Cutting System Installed by WARDJet; Just IN-big scale ---laser cutting machine; Cnc that work for small scale jewelry and medium size wood cutting - what to buy

CNC routers can indeed cut steel, but their capabilities depend on several factors including the machine’s power, rigidity, and the specific type of steel being cut. Most standard CNC routers are designed for softer materials like wood, plastics, and aluminum, making them less suitable for cutting harder metals like steel.Half of people say you can't cut steel on a CNC router, and then other people post videos of them doing it. . finding that small sweet spot of slower speeds and big enough chips is possible on a hobby machine, but only at very shallow depths, which means your going to use the bottom 1/16 of an inch of the endmill only, which wears out the .

I used Solid Works cam 2022 and created my own tool library with all the tools we use on the CNC machine. I am certain that the tools were set correctly and all the diameters were correct. So now with the same tool in the CNC machine and two differently generated g-codes, the result comes out different. And I can't figure it out why this is .

A non-woven porous material with a special coating enables vacuum chucks and tables to hold sheets of metal and other materials more effectively on CNC routing machines. The material, called Vilmill, is used as a .This article will demonstrate a simple way to cut aluminum spur gears on a small desktop cnc hobby mill. I also made a short video of my Taig mill cutting the gear, you can see this later in the article. Gear cutting on a vertical milling machine. .

Carving a larger aluminum block for a belt buckle so need bigger bits that can remove more material. I know I'll be limited to pretty slow speed based on the power of the machine but I at least want to get bits that won't snap or dull immediately. Thanks for any recommendations/advice!I’ve been dabbling for a few years in being a prototype shop and small job shop. I would like my cnc machine to be paid off in 3 years. So 3 x 40 x 52 = 6240 hours. Cost of my machine divided by that, plus my monthly maintenance, plus my tooling costs, plus energy costs, plus my regular shop supplies rate that includes things like insurance . In wood you might never reach the spindles rated horsepower output so your depth of cut "can" be deeper. . to use 1/8 cutters and if that is the case you will likely be better off going fast with relatively shallow depths of cut. The small diameter means deflection will be very real and chip clearance could be a problem too. . All CNCzone .It can cut that small. For Christmas last year I've cutted a lot of snowflakes with sizes between 1 and 2 cm without a problem. Cut slow and weed even slower. But a lot depends on the quality of the vinyl. Htv usually won't give problems. Make sure you cut on slow speed and it if isn't working out, try another brand of vinyl.

Small CNC milling machines are a game-changer for hobbyists and small businesses alike. These compact machines offer a range of advantages, including precise and efficient metal cutting, cost-effectiveness, and space-saving design. With a small CNC milling machine, you can take on intricate projects with ease and confidence. Yes, a CNC router can cut brass, which is a non-ferrous metal that is softer and more easily machinable than harder metals like steel. . We also have a large network of UK clients who have our range of CNC machines. We can facilitate live demos in Ireland, the UK & EU directly, when mobile, or via our existing client base. If you would like . In this video, Ryan shows you how to cut materials larger than your CNC Machine - this technique is going to help you get the most out of your WorkBee CNC Ma. The shrinking size and price of CNC machines have fueled a boom in CNC-crafted goods, flooding online markets like Etsy, Amazon, and Facebook Marketplace, and featuring in local craft fairs. CNC routers can cut any shape from a variety of materials. There’s an extensive list of products you can create with a CNC machine. What makes a great .

Hi! Would love to hear if anyone else has experience with Xometry and how good it can be to grow a business on. Thank you so much for your thoughts. I just started a small machine shop in my garage with a Haas CM1. My goal is to make a bit of extra money and maybe even get to the point that I can have a business and quit my day job.I need a very small CNC that is reasonably priced and can machine. 316 stainless steel, we will be doing very fine cuts - maximum of .5mm, this is surfacing products that simply need machining for fitting of parts etc. all of the pieces are 45x45x12 mm max dimension.

Twin/Full angle steel bed side rails are designed to fit either Twin or Full-Size Beds. To use these rails, the pins inside the slot of your headboard and footboard should be 2 inches apart. Opens in a new tab

how small can a cnc machine cut|depth of cnc router cutting