aircraft cnc machining Precision machining in aerospace enables manufacturers to shape large pieces of material into more precise parts using computer numerical control (CNC) equipment. Parts are available from Stiles 24 hours a day, seven days a week, and are shipped from our Grand Rapids, Michigan fulfillment center. 24/7 Parts: 800-727-8780. Complete Our Contact Form

0 · what is aerospace cnc machining

1 · cnc machining aerospace parts

2 · cnc aircraft type

3 · cnc aerospace parts

4 · aerospace manufacturing cnc machining

5 · aerospace connector manufacturing machine

6 · aerospace cnc machining services

7 · aerospace cnc machine shop

Handcrafted and locally sourced right here in the U.S.A., we create luxury steel doors and partitions that stand the test of time. As an award-winning team of fabricators and engineers, we see every project as a unique opportunity to blend art and function.

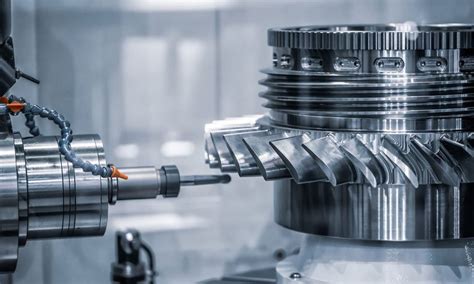

What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and . What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, .Precision machining in aerospace enables manufacturers to shape large pieces of material into more precise parts using computer numerical control (CNC) equipment.Aircraft CNC machining is used to create the internal structures for an airplane’s vertical and horizontal stabilizers, as well as aerodynamic surfaces that provide longitudinal (pitch) and/or .

what is aerospace cnc machining

cnc machining aerospace parts

Aerospace CNC machining is a subtractive manufacturing technique that involves creating and maintaining aircraft and space shuttle components with computer numerically controlled tools. This automated . In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface . The aerospace CNC machining process involves using computer-controlled machine tools to shape raw materials, such as metals or composites, into finished aerospace components. The process starts with a digital 3D .

In aircraft manufacturing, aerospace CNC machining is crucial for producing lightweight yet durable components that meet stringent safety and performance standards. From fuselage parts to avionics enclosures, CNC machines play a .

Today, every sector within the aerospace industry uses CNC machining. For producing screws and other long, thin parts that must meet specific tolerances, many shops use Swiss machining. For complex parts with . CNC machining for the aerospace industry has proven to be a valuable asset for manufacturers. But what does aerospace CNC machining entail? This in-depth guide looks at . What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and spacecraft.

junction box for exterior wall sconce

cnc aircraft type

junction box extension menards

What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry.Precision machining in aerospace enables manufacturers to shape large pieces of material into more precise parts using computer numerical control (CNC) equipment.Aircraft CNC machining is used to create the internal structures for an airplane’s vertical and horizontal stabilizers, as well as aerodynamic surfaces that provide longitudinal (pitch) and/or directional stability and control. Aerospace CNC machining is a subtractive manufacturing technique that involves creating and maintaining aircraft and space shuttle components with computer numerically controlled tools. This automated manufacturing process uses cutting tools controlled by pre-programmed code and software.

In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface treatments, and applications that make this technology so essential to the industry.

The aerospace CNC machining process involves using computer-controlled machine tools to shape raw materials, such as metals or composites, into finished aerospace components. The process starts with a digital 3D model .In aircraft manufacturing, aerospace CNC machining is crucial for producing lightweight yet durable components that meet stringent safety and performance standards. From fuselage parts to avionics enclosures, CNC machines play a vital role in creating the intricate pieces needed for modern aircraft. Today, every sector within the aerospace industry uses CNC machining. For producing screws and other long, thin parts that must meet specific tolerances, many shops use Swiss machining. For complex parts with odd geometries like the combustion components in modern turbines, many shops use multiaxis machining.

CNC machining for the aerospace industry has proven to be a valuable asset for manufacturers. But what does aerospace CNC machining entail? This in-depth guide looks at the details of aerospace CNC machining. Read on to discover the applications, materials used, and the most popular surface finishes for CNC machined parts in this industry. What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and spacecraft. What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry.

cnc aerospace parts

Precision machining in aerospace enables manufacturers to shape large pieces of material into more precise parts using computer numerical control (CNC) equipment.

Aircraft CNC machining is used to create the internal structures for an airplane’s vertical and horizontal stabilizers, as well as aerodynamic surfaces that provide longitudinal (pitch) and/or directional stability and control.

Aerospace CNC machining is a subtractive manufacturing technique that involves creating and maintaining aircraft and space shuttle components with computer numerically controlled tools. This automated manufacturing process uses cutting tools controlled by pre-programmed code and software.

In this comprehensive guide, we’ll take a deep dive into the world of aerospace CNC machining, exploring the materials, benefits, cutting tools and strategies, surface treatments, and applications that make this technology so essential to the industry. The aerospace CNC machining process involves using computer-controlled machine tools to shape raw materials, such as metals or composites, into finished aerospace components. The process starts with a digital 3D model .In aircraft manufacturing, aerospace CNC machining is crucial for producing lightweight yet durable components that meet stringent safety and performance standards. From fuselage parts to avionics enclosures, CNC machines play a vital role in creating the intricate pieces needed for modern aircraft.

Today, every sector within the aerospace industry uses CNC machining. For producing screws and other long, thin parts that must meet specific tolerances, many shops use Swiss machining. For complex parts with odd geometries like the combustion components in modern turbines, many shops use multiaxis machining.

junction box for brimar trailer

As a first step in designing an enclosure, you need to choose the type of metal you will use and its thickness. Protocase stocks all of the metals generally used to make enclosures, including aluminum, stainless steel, carbon steel (cold-rolled steel or galvanneal) and copper.

aircraft cnc machining|aerospace cnc machine shop