bracket sheet metal design But how do you go about creating a sheet metal bracket? 3ERP has years of expertise in sheet metal prototyping, and this guide explains the basics of sheet metal brackets, including common bracket types, bracket . Indeed, a range is another name for a freestanding electric oven/cooktop combination. As to your tripping problem -- random trips on different circuits with no sign of an overload is a sign that the breaker panel busbars are on their way out, and trying to burn your house down in the process.

0 · sheet metal rib design guidelines

1 · sheet metal fabrication design guide

2 · sheet metal design guidelines pdf

3 · sheet metal design calculations pdf

4 · sheet metal bracket design guidelines

5 · sheet metal basic design guidelines

6 · existing designs for brackets

7 · basics of sheet metal design

How important is 3D nesting Our operations (both on CNC and laser systems) are all 2D paths. The value in parts identification is negligible, since the CNC operations will include a marking job to label parts, but could be beneficial for auditing or cataloguing parts.

In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore different bracket types, . Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending. When it comes to sheet-metal brackets, there are several standard styles and shapes. Each sheet metal bracket style serves a specific requirement for mounting a component, or being compatible with a particular surface shape.

But how do you go about creating a sheet metal bracket? 3ERP has years of expertise in sheet metal prototyping, and this guide explains the basics of sheet metal brackets, including common bracket types, bracket .

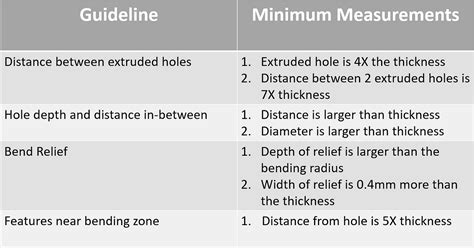

Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.Creating a hem in sheet metal requires special tooling and machinery, often involving press brakes or other sheet metal forming equipment. Proper design and execution of hems is essential to ensure they don't split or deform during .

In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore different bracket types, and share tips to help you design the ideal custom brackets for your applications.

Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending.So you decided to design your own sheet metal part. Use the following simple guidelines to formulate and design the type of sheet metal bracket you will need to successfully meet your requirements. The starting point is determining what loading . When it comes to sheet-metal brackets, there are several standard styles and shapes. Each sheet metal bracket style serves a specific requirement for mounting a component, or being compatible with a particular surface shape.

But how do you go about creating a sheet metal bracket? 3ERP has years of expertise in sheet metal prototyping, and this guide explains the basics of sheet metal brackets, including common bracket types, bracket design tips, and the best sheet metal bracket materials.Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.Creating a hem in sheet metal requires special tooling and machinery, often involving press brakes or other sheet metal forming equipment. Proper design and execution of hems is essential to ensure they don't split or deform during the bending process.

The use of sheet metal in crafting brackets offers excellent durability, versatility, and cost-effectiveness, ensuring robustness in various application scenarios, from mounting heavy equipment to supporting shelves.Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed . Design considerations and question to ask in sheet metal bracket design. What material to choose for the sheet metal part? Steel? Aluminum alloy? Or any other metal? If chosen then which grade? Whether the steel selected is formable / bendable easily. Whether the grade and thickness is available?

In this guide, we share some background on the processes we use to manufacture custom sheet metal brackets, explore different bracket types, and share tips to help you design the ideal custom brackets for your applications. Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending.

So you decided to design your own sheet metal part. Use the following simple guidelines to formulate and design the type of sheet metal bracket you will need to successfully meet your requirements. The starting point is determining what loading . When it comes to sheet-metal brackets, there are several standard styles and shapes. Each sheet metal bracket style serves a specific requirement for mounting a component, or being compatible with a particular surface shape. But how do you go about creating a sheet metal bracket? 3ERP has years of expertise in sheet metal prototyping, and this guide explains the basics of sheet metal brackets, including common bracket types, bracket design tips, and the best sheet metal bracket materials.Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.

Creating a hem in sheet metal requires special tooling and machinery, often involving press brakes or other sheet metal forming equipment. Proper design and execution of hems is essential to ensure they don't split or deform during the bending process. The use of sheet metal in crafting brackets offers excellent durability, versatility, and cost-effectiveness, ensuring robustness in various application scenarios, from mounting heavy equipment to supporting shelves.Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .

sheet metal rib design guidelines

sheet metal fabrication design guide

sheet metal design guidelines pdf

Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, showcasing a blend of technical skills and creativity.

bracket sheet metal design|sheet metal rib design guidelines