metal sheet vs plate The difference between a metal sheet and metal plate can be defined by thickness. If the thickness of the metal is ¼” (6mm) or more, then it is considered a plate. Plate thickness is typically measured in inches. Metal fabricators use tools to shape, cut, and assemble metal structures. It’s like how a painter needs brushes and rollers to paint. In the shop, each project requires a variety of strong, reliable tools.

0 · steel sheet vs plate

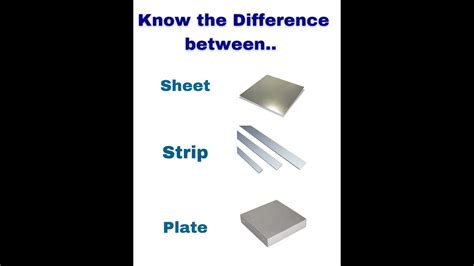

1 · sheet metal vs steel plate

2 · plates sheets and strip

3 · plate vs sheet strip

4 · foil vs sheet plate

5 · flat bar vs plate steel

6 · difference between sheet and strip

7 · aluminum plate vs sheet

4 axis machining implies that a workpiece is processed in the same way it would be with a 3 axis machine, but has an additional rotary movement around the X axis, which is named the A axis. This rotation allows the workpiece to be cut around the B axis.

The primary difference between steel sheet and steel plate lies in their thickness and the specific applications they are designed for. Steel sheets are thinner, typically ranging from 0.5 mm to less than 6 mm in thickness, and . The difference between a metal sheet and metal plate can be defined by thickness. If the thickness of the metal is ¼” (6mm) or more, then it is considered a plate. Plate thickness is typically measured in inches.

While some people outside of the industry may think of “sheets” and “plates” as interchangeable, it’s important to understand that these words refer to two different metal products. Sheets may be more commonly used for .

bhw sheet metal company

When deciding between a steel sheet and a steel plate, consider thickness as the main difference. Steel Sheets: Typically thinner, from 0.5 mm . For Structural Applications: If strength, rigidity, and load-bearing capacity are paramount, steel plates are the preferred choice. For Precision and Appearance: When a smooth finish, precise dimensions, and formability are . Metal sheet reflects any metal from 0.5mm up to 6mm. Metal foil with the thinnest options. Metal foil is categorized by sheet metal with a thickness less than 0.2mm. US-based .Generally speaking, a sheet is a thinner item of metal that has been cut from a continuously rolled coil. As such, it can be less than 1mm, or up to 25mm, in thickness. A plate is a thicker item of .

Get all the information you need about sheet vs plate steel, including metal thickness comparison and the different types of steel products.

steel sheet vs plate

Measurement. Steel Plate: Steel with a thickness of 3/16′′ or more and a width of more than 10′′. Steel Sheet: Metal with a thickness of less than 3/16′′ and a width of 24′′ or .A plate is a thicker item of metal that has been produced (rolled) as a single item. Thickness can be up to 150mm or more, but also as low as 2mm from certain producers. Therefore, it’s quite possible that certain thickness items could be produced via either process and described differently, although both are in the hot rolled condition.

Stainless Steel Vs. Aluminum Sheet Metal & Plate. Material Options. Different properties of stainless steel and aluminum, which are used in sheet metal and plate applications respectively. The alloys differ in .Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, Delivered Anywhere! Select Size; 1 .

One of the main differences between Aluminum Plate and sheets is that sheet metal is under .249” thick, while plate metal is .250” and above.. Another difference between Aluminum Plate and sheets has to do with the distinct applications for which they are used. Sheets. Sheet is the form of aluminum that is used the most often.

Sheet metal vs plate steel is a kind of metal material, which is widely used in industrial production and manufacturing. Characteristics of Sheet VS Plate Steel. The plate has a larger area and thickness, higher hardness and strength, and greater weight and strength.sheet vs plate. sheet vs plate is a shiny smooth plate used in a variety of applications. Our sheet vs plate range in thickness from 0.6mm to 6mm. You are able to buy less than full-sized sheets and we can to guillotine these to your size . sheet vs plate are sold as mill finish and clear anodised finish is available in 1.6 and 3mm thickness.

Stainless Steel Metal Sheet vs Plate While stainless sheets and plates sound like the same product, they differ in thickness and durability. The difference between stainless steel sheet and plate can quickly be determined by checking the stainless steel sheet gauge; the higher gauge stainless steel thickness, the thinner the metal.

The primary difference between sheet metal and plate rolling is the thickness of the metal used. Sheet metal is typically thinner than 6 mm (0.25 inches), while plate is thicker than 6 mm (0.25 inches). This difference in thickness affects the type of equipment and techniques used for rolling. EquipmentThere are many hundreds of types and sizes of plate and sheet vs plate in aluminummetals’s stock range. For non-stock sizes, through our reserved allocation, lead times can be scheduled to meet your requirements. aluminummetals’s stock range of aluminium plate and sheet vs plate contains numerous sizes, alloys, and tempers. It includes: The metal you use will fully depend on your needs. To help you better understand this, here is a quick run-through of the applications of metal sheets, plates, and foils. Metal Plates: Stainless steel plates are commonly used for industrial applications like construction or applications that require hygienic properties. This is why plate metal .

Sheet is among the most common metal products, normally defined as any aluminum or stainless steel that is less than a quarter of an inch thick. Anything below one thousandth of an inch is considered foil, while anything .25” and greater is considered a plate product. Steel plate metal is the thickest designation. Any sheet metal thicker than 6mm is known as plate metal. Steel plate is durable but heavy. It’s used in applications where strength is more important than saving weight. Applications. Metal foil, sheet metal, and plate metal are designated by their thickness, not by their chemical and physical .

bhw sheet metal company jonesboro ga

III. Frequently Seen Japanese Grades in General and Mechanical Structural Steel Plates. 1. The designation of Japanese steel (JIS series) in general structural steel is mainly composed of three parts: the first part indicates the material, such as: S (Steel) represents steel, F (Ferrum) represents iron; the second part represents different shapes, types, uses, such as P .Metal Sheets, Bars, & Rods / Metal Sheets Sort by. Most Popular. Pickup & Delivery Brand Price Gauge Finish All filters. 74 items in Metal Sheets. Save 10%. When you Buy Online Pickup In Store . Hillman SteelWorks 12 in. x 24 in. #16 Weldable Solid Steel Sheet. 5 (6) | Item # 350590299. Pickup Today. FREE. Same Day Delivery. Standard Delivery .The plate is a piece of metal which has a thickness of more than 3 mm. It may be of any type of metal like steel, aluminum, etc. Difference Between Plate and Sheet Metal. Plate and sheet are words which we use to describe the .Hot Rolled Steel. This is the most common and simple finish and the first step to making steel plates and sheets. A steel slab is heated, typically to 1,700 degrees F, and passed through a series of rollers - .

Burbank metal supply is another supplier who has remnants and drops. The owner is a lot more friendly and service-oriented than IMS. I forget the spot, but there is a place in the Long Beach area that does huge amounts of nice clean sheet/plate - they sort and stockpile it, and also list it on eBay. Their prices are reasonable.Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. The equivalent thicknesses differ for each gauge size standard, which were developed based on the weight of the sheet for a given material. The Manufacturers' Standard Gage provides the thicknesses for .

sheet metal vs steel plate

plates sheets and strip

Plate metal is any 6 mm thick or larger piece of metal. Plate metal is used in systems where reliability is of greater value than weight savings. This is used in cars where it needs longevity to undergo crash inspection. The Difference. Plate and sheet are terms that are used to define the metal type according to its thickness. While sheet . Usable sheets or plates require reduced thickness. Hot or cold rolling is used to reduce and standardizethickness for the full length of a product. Measuring Plates. If the product has a thickness of 3/16 inch or more after the rolling process, the product is considered a metal plate. Because metal plates tend to be structural, thickness is .Sheet Metal: Sheet metal is any metal with a thickness of 0.5-6 mm. It is thicker than a foil but thinner than a plate. It is thicker than a foil but thinner than a plate. Sheet metals are used in building structures that do not require durability and are often corrugated or diamonded for additional strength without increasing weight.So, whether you’re working on a high-tech automotive project or a massive industrial fabrication, the choice between sheet metal and plate metal is a critical one that can make all the difference in the world. The Verdict: Choose Wisely, My Friends. Alright, so there you have it – the epic battle of sheet metal vs. plate metal.

big bear sheet metal

When comparing aluminum sheets and plates, the critical distinction lies in their thickness: Aluminum Sheet: Characteristically thinner, with a thickness range from 0.008 inches (0.2 mm) to 0.25 inches (6.35 mm). Aluminum Plate: Notably thicker, typically commencing at 0.25 inches (6.35 mm) and extending up to 6 inches (150 mm) or beyond. Sheet metal and gauge size, changes to what the industry calls plate metal after crossing over 7GA (.188). After that, metal is measured and called out by decimal equivalents. A ¼”-thick metal is called out, you guessed it, by .250. Sheet metal fabrication and plate metal fabrication are very often different niches. A metal sheet is like your favorite slice of pizza—thin and flexible. Plate metal, on the other hand, is like a thick, hearty slab of meatloaf. It’s substantial and robust. The difference in thickness dictates their strength and flexibility and guides their use in various applications. When To Use Sheet Metal vs. Plate Metal. Choosing .

2. Sheet Metalworking Defined Cutting and forming operations performed on relatively thin sheets of metal Thickness of sheet metal = 0.4 mm (1/64 in) to 6 mm (1/4 in) Thickness of plate stock > 6 mm Operations usually performed as cold working ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/e I have things listed like 3/16", 1/4", 1/2" and 3/8" plate listed as Plate, where as I have another category for sheet metal like: 24 gauge to 7 gauge sheet metal. This means that when ever a search is done for a part number you have to look in another place besides sheet to find the material listed as plate.

plate vs sheet strip

What is a Junction box? What is the importance of the junction box in an instrument control system? What are the major parts of the junction block? How field instruments are wired to the junction box? What are the .

metal sheet vs plate|aluminum plate vs sheet