asbestos electrical box Asbestos wire insulation was extremely resistant to moisture and chemicals, preventing corrosion and damage in tough environments, like industrial buildings or extreme outdoor climates. It . Get instant online quote for your metal or plastic CNC machined parts, from rapid prototyping to production. Tolerance down to 0.001 inches. Choose from 100+ materials, 60+ surface finishes. ISO 9001:2015, ISO 13485, ISO14001:2015, IATF 16949:2016 certified. Experience lead times as short as 1 day. Start a New CNC Project!

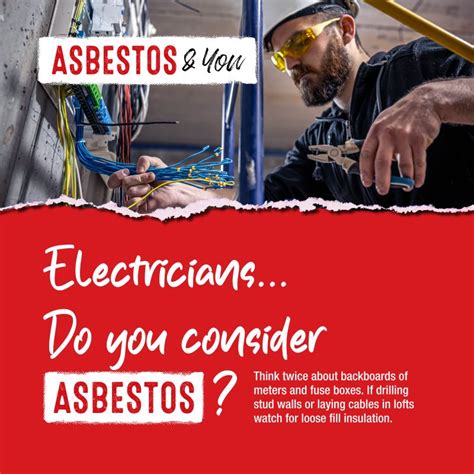

0 · asbestos protection for electricians

1 · asbestos in electrical systems

2 · asbestos in electrical industry

3 · asbestos in electrical equipment

4 · asbestos in electrical boxes

5 · asbestos for electrical wiring

6 · asbestos exposure to electrical equipment

7 · asbestos electrical panels

We offer instant online quotes, payment and ordering for high-quality, high-precision, custom metal parts – straight from our factory. Get exact pricing in 30 seconds! Upload your 3D drawings to our secure platform in STP, STEP, or SLDPRT formats. Choose your desired material, surface finishes and tolerance requirements.

Employers must identify the presence of asbestos before any electrical or other work is carried out that is liable to disturb asbestos (CAR 2012, Regulation 5). This ‘work’ includes access or .Asbestos wire insulation was extremely resistant to moisture and chemicals, preventing corrosion and damage in tough environments, like industrial buildings or extreme outdoor climates. It . Asbestos was once commonly used in electrical wiring, electrical panels, cable wrap, and other products electricians handled regularly. Electricians working with wiring in older buildings are at risk of asbestos exposure and .

Asbestos was believed to be a safe way to keep electric wires well-insulated and protect them from corrosion. However, manufacturers of asbestos-containing electrical wiring .

Electrician asbestos exposure can involve removing felted asbestos insulation around old wiring or inside breaker boxes. A 2021 study reported that older arc chutes contained roughly 36% chrysotile asbestos .Fire resistance: Asbestos is highly resistant to heat and flames, making it an excellent choice for insulating electrical components and equipment. In case of a short circuit or electrical fault, the presence of asbestos could help contain or .

Heaters – Heat can cause asbestos-containing electrical wire to degrade over time. This makes it much easier for asbestos fibers to be released into the air. Electrical paper – This is also known as a flash guard, which was .

Up until the late 1970s the very materials that electricians installed, removed and maintained contained asbestos. Normal use of these items do not pose a hazard, but when these items are installed, drilled, filed, or removed, asbestos fibers . Electricians may have been exposed to asbestos in electrical and construction products. Asbestos exposure can lead to the development of diseases such as mesothelioma and asbestosis. Electricians are responsible . Asbestos protected building tenants from fire and electrocution but also exposed electricians and other workers to severe health risks. The electricity for a building is received and distributed through a device called an electrical panel or distribution box.

Employers must identify the presence of asbestos before any electrical or other work is carried out that is liable to disturb asbestos (CAR 2012, Regulation 5). This ‘work’ includes access or preparatory work, etc. around electrical equipment.Asbestos wire insulation was extremely resistant to moisture and chemicals, preventing corrosion and damage in tough environments, like industrial buildings or extreme outdoor climates. It was also heat-resistant, helping reduce the risk of fires due to sparks from electrical shortages. Asbestos was once commonly used in electrical wiring, electrical panels, cable wrap, and other products electricians handled regularly. Electricians working with wiring in older buildings are at risk of asbestos exposure and developing mesothelioma or other illnesses associated with asbestos.

Asbestos was believed to be a safe way to keep electric wires well-insulated and protect them from corrosion. However, manufacturers of asbestos-containing electrical wiring hid a deadly truth: Exposure could lead to mesothelioma and . Electrician asbestos exposure can involve removing felted asbestos insulation around old wiring or inside breaker boxes. A 2021 study reported that older arc chutes contained roughly 36% chrysotile asbestos within the plastic molding used .Fire resistance: Asbestos is highly resistant to heat and flames, making it an excellent choice for insulating electrical components and equipment. In case of a short circuit or electrical fault, the presence of asbestos could help contain or prevent fires from spreading.

Heaters – Heat can cause asbestos-containing electrical wire to degrade over time. This makes it much easier for asbestos fibers to be released into the air. Electrical paper – This is also known as a flash guard, which was put into electrical boxes to help prevent fires.Up until the late 1970s the very materials that electricians installed, removed and maintained contained asbestos. Normal use of these items do not pose a hazard, but when these items are installed, drilled, filed, or removed, asbestos fibers can become airborne.

Electricians may have been exposed to asbestos in electrical and construction products. Asbestos exposure can lead to the development of diseases such as mesothelioma and asbestosis. Electricians are responsible for assisting with . Asbestos protected building tenants from fire and electrocution but also exposed electricians and other workers to severe health risks. The electricity for a building is received and distributed through a device called an electrical panel or distribution box.Employers must identify the presence of asbestos before any electrical or other work is carried out that is liable to disturb asbestos (CAR 2012, Regulation 5). This ‘work’ includes access or preparatory work, etc. around electrical equipment.Asbestos wire insulation was extremely resistant to moisture and chemicals, preventing corrosion and damage in tough environments, like industrial buildings or extreme outdoor climates. It was also heat-resistant, helping reduce the risk of fires due to sparks from electrical shortages.

Asbestos was once commonly used in electrical wiring, electrical panels, cable wrap, and other products electricians handled regularly. Electricians working with wiring in older buildings are at risk of asbestos exposure and developing mesothelioma or other illnesses associated with asbestos. Asbestos was believed to be a safe way to keep electric wires well-insulated and protect them from corrosion. However, manufacturers of asbestos-containing electrical wiring hid a deadly truth: Exposure could lead to mesothelioma and . Electrician asbestos exposure can involve removing felted asbestos insulation around old wiring or inside breaker boxes. A 2021 study reported that older arc chutes contained roughly 36% chrysotile asbestos within the plastic molding used .

Fire resistance: Asbestos is highly resistant to heat and flames, making it an excellent choice for insulating electrical components and equipment. In case of a short circuit or electrical fault, the presence of asbestos could help contain or prevent fires from spreading. Heaters – Heat can cause asbestos-containing electrical wire to degrade over time. This makes it much easier for asbestos fibers to be released into the air. Electrical paper – This is also known as a flash guard, which was put into electrical boxes to help prevent fires.Up until the late 1970s the very materials that electricians installed, removed and maintained contained asbestos. Normal use of these items do not pose a hazard, but when these items are installed, drilled, filed, or removed, asbestos fibers can become airborne.

asbestos protection for electricians

asbestos in electrical systems

asbestos in electrical industry

From precision CNC machining to complete fabrication, Pierce Aluminum delivers your project on spec, on time, and on budget. Our one-stop shops can handle any task from simple parts to final assembly of any size project.

asbestos electrical box|asbestos in electrical equipment