sheet metal deep drawn part Deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die. It allows for superior quality components, produced at high speeds, and often at lower costs than competing methods. . The deep drawn part starts as flat material which is cut into circular blanks from a strip of metal. The .

Discover the best glue for glass, fabric, ceramics, metal, organic materials, paper, plastic, Styrofoam, and wood. Print out this infographic as your helpful go-to next time you need to adhere two items together.

0 · sheet metal deep drawing calculations

1 · products made by deep drawing

2 · metal spinning vs deep drawing

3 · deep drawing vs stamping

4 · deep drawing process step by

5 · deep drawing calculation

6 · deep draw sheet metal forming

7 · deep draw blank size calculation

We do the unboxing of Apple iPhone XR! Click ''show more''.If you’re interested in finding out what the factory box of the iPhone XR brings us, we are here t.

sheet metal deep drawing calculations

Deep drawing, at its essence, is a sheet metal forming process where the metal sheet is radially drawn into a forming die by the mechanical action of a punch. The depth of the formed part can be greater than its .

Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains essentially the same from start to .

Step-1 : Part Alignment. Place the sheet metal blank inside the deep drawing die after sheet metal blanking operation. Step-2: Gripping. Shank holder grips the sheet metal blank in between the die and shank holder with the required . Deep Drawing involves pulling the metal sheet into a die to create a part with a significant depth compared to its width. It’s ideal for making hollow, cylindrical shapes like cans or automotive fuel tanks. The metal is drawn multiple times, hence the term “deep drawing,” to achieve deeper forms without breaking.

Welcome to this comprehensive guide on deep drawing, a process integral to the world of metal forming.At its core, deep drawn metal stamping is a method used to shape metal sheets into complex geometries. The deep draw stamping .Deep drawing is a type of metal forming process where parts are produced by punching sheet metal into a formed die. It allows for superior quality components, produced at high speeds, and often at lower costs than competing methods. . The deep drawn part starts as flat material which is cut into circular blanks from a strip of metal. The . Deep drawing produces a part from a flat blank via the action of a punch force onto the blank. That force pulls (draws) the blank into a die cavity, causing the flange to compress circumferentially. . The recommended punch and die radii as a function of sheet thickness are shown in Figs. 4 and 5, respectively. Fig. 4: . design parameters .Deep drawing is fundamentally a metal sheet-forming technique that turns a flat metal sheet into a three-dimensional product. . durability, and reliability are not just lovely but essential. Deep drawing is a vital part of the automotive industry, and we at Shengen are proud to be a part of it. . Deep-drawn metal cones are responsible for .

products made by deep drawing

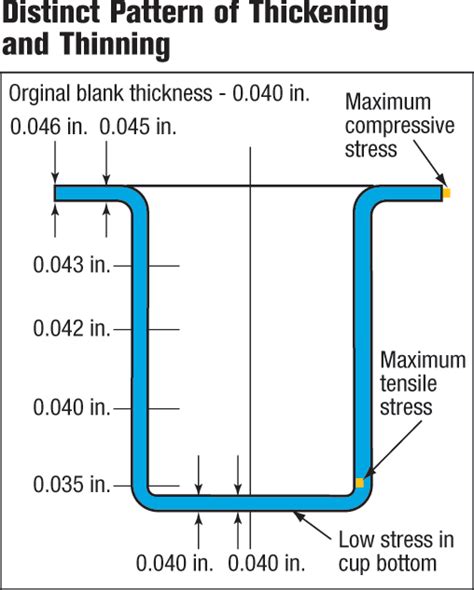

When designing a part for deep drawing, the designer must consider that the process is constrained by the sheet metal’s bending and stretching limitations. These limitations need to be considered when determining wall thickness, corner radii, and other features to ensure that the part can be successfully deep drawn.Brief Overview Of Deep-Drawn Metal Stamping. Deep-drawn metal stamping is a pivotal process in metal stamping part manufacturing, offering notable advantages in terms of precision and efficiency.Neway, a leading custom stamping parts manufacturer, leverages deep-drawn metal stamping as part of its comprehensive suite of manufacturing methods.. In this process, flat . Deep Drawing Forming of Sheet Metal. . Among them: e represents the minimum straight edge length, f represents the maximum size of the deep-drawn part, a represents the short axis length, and 6 represents the long axis length. 4.2 For cylindrical drawn parts with flanges, when drawing with a blank holder, the most suitable flange is in the .

Manufacturers will repeat the deep drawn method as needed until a part has taken the desired form. . We work with flat materials like sheet metal to create products such as deep drawn containers. Our team typically uses Aluminum Association alloys with government designations for deep drawn products. However, as many materials are compatible . seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains essentially the same from start to finish. A deep drawn part can be recognized by its depth Sheet metal deep drawn is a process of transforming a flat sheet of metal into a three-dimensional part through a series of steps. The process starts with a flat sheet of metal, which is then placed over a die (a tool with a desired shape). A punch is then used to push the sheet into the die cavity, causing the metal sheet to deform and take up .

Deep drawing is a metal forming process used to produce complex, high-quality components from sheet metals. It is widely employed in industries to create parts like automotive components, kitchen sinks, and beverage cans. The deep draw process is crucial for producing components by transforming flat metal sheets into hollow, cylindrical, or box-shaped parts through the use of a .

Our hydraulic sheet metal forming processes accommodate part diameters that fit within a 96” x 120” press envelope. . and pierce operations between 2 or 3 presses to create one piece flow whenever practical. Allowing for deep-drawn part production runs with high volumes and the benefit of cost-saving operations. From small to large deep .Deep Drawing, on the other hand, is a specialized form of stamping that draws the metal sheet into a die by a mechanical action, creating a part whose depth can exceed its diameter. This process is ideal for manufacturing components .Metal Stamping Parts Supplier, Stamped Deep Drawn Part, Stamping Sheet Metal Parts Manufacturers/ Suppliers - Hengshui Kanghe Medical Equipment Trading Co., Ltd.

In deep drawing, a piece of sheet metal is placed onto a die cavity and then forcing the metal into the cavity using a punch; the sheet metal is radially drawn into the die cavity by the mechanical action of the punch (see Fig. 12.2).In order to perform a deep drawing operation, first the sheet metal is put onto the die, and then a blank-holder (cushion pad) is introduced on the .In this process, a metal sheet or part is clamped at its edges and then stretched over a die or form block, utilizing the tensile strength of the material. . Besides creating diverse deep-drawn metal stampings down to 0.01 inches; they additionally make specialties such as short-run coin enclosures and even eyelet ferrules within plus or .

The deep drawn stamping process is an efficient metal-forming method that creates complex shapes efficiently and precisely. This process involves drawing a blank metal sheet into a forming tool and transforming it into intricate designs. This method produces high-quality components at lower costs, particularly for large production runs.Sheet metal stamping is used to transform flat metal sheets into specific shapes in precison. Stamping of sheet metal is a process based on permanent deformation by cold forming to produce a variety of complex three-dimensional shapes. Tensile forces with a high ratio of surface area carry out the process to thickness.

The study presented in this paper addresses the inspection of deep drawn parts using rectangular cups as an example. For this purpose, a corresponding deep drawing tool was mounted in the servo mechanical press (Aida NST-S2-6300(D)-305-150-SERVO) of the Institute for Metal Forming Technology in Stuttgart and 30 cup parts were manufactured.

metal spinning vs deep drawing

Deep Drawing Sheet Metal: Hydraulic deep drawing presses are an essential piece of equipment in the manufacturing industry, utilized for forming sheet metal. . a punch. The process transforms the flat sheet into a hollow, cylindrical, or box-shaped part, where the depth of the drawn part is often greater than its diameter. This method . During the process of deep drawing, sheet metal blanks are pushed into a die cavity by a punch. This produces a part that is contoured. If a part’s depth is half its diameter or more, it qualifies as deep drawn. The term “general stamping” describes parts that do not meet these criteria. The process of deep drawn stamping is used .How to Collaborate with a Wholesale Sheet Metal Deep Drawn Part Factory. 1. Define Your Requirements: Clearly communicate your specifications, including material, dimensions, tolerances, and quantity. 2. Request Samples: Ask the wholesale factory to provide samples of their deep drawn parts so you can assess the quality and suitability for your . Deep drawing is a metal forming process where a flat sheet of metal is formed into a three-dimensional shape by being drawn into a die cavity. The success of deep drawing operations is influenced by factors such as the height-to-diameter ratio of the drawn part, the presence of excessive edge wrinkling, and the drawing ratio (DR) which is .

Deep Draw Components, Sheet Metal Components & Deep Drawn Shell Manufacturer offered by Krishna Industries from Ahmedabad, Gujarat, India. Krishna Industries. Odhav, Ahmedabad, Gujarat. GST No.-24AFHPS8583C1Z6. Call 08048609465. 84% Response rate. Send Email. Products & Services.Deep draw tooling includes all the hard tooling components used to shape flat sheet metal into a deep-drawn part: Dies; Punches; Blank holders; Knockout cylinders; Dies and punches are made of tool steel, while blank holders and knockout cylinders are typically made of alloy steel. The rims of the punch and drawing ring are rounded so the sheet .

deep drawing vs stamping

metal roof on brick house with white doors and windows

At the time, you might have glanced at the token and thought it was just a simple decoration, but the symbol can actually have an important meaning behind it. In December 2020, Niagara community newspaper The .

sheet metal deep drawn part|deep drawing vs stamping