2 how do sheet metal forming processes differ from forging How does sheet-metal forming differ from rolling, forging, and extrusion? Punching is used to create holes or features in metal sheets and blanching is used to cut out the blanks or shapes . Our online parts superstore carries a wide variety of factory-certified, specialty and aftermarket parts. Find online Fleetwood RV owners’ manuals for your 1974-2022 Fleetwood RV .

0 · what is forming in metalworking

1 · sheet metal forming techniques

2 · sheet metal forming equipment

3 · sheet metal forming

4 · sheet metal bending process

5 · forging vs forming metal

A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one.

How does sheet-metal forming differ from rolling, forging, and extrusion? Sheet metal forming is usually done at room temperature. Instead of forcing the metal to flow into a new shape, as in rolling, forging, and extruding, sheet metal .Instead of forcing the metal to flow into a new shape, as in rolling, forging, and extruding, sheet metal forming involves causing plastic deformation in the overall material without much change .How does sheet-metal forming differ from rolling, forging, and extrusion? Punching is used to create holes or features in metal sheets and blanching is used to cut out the blanks or shapes ..describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects .

How Does the Simulation Process Differ Between Sheet Metal Forging and Sheet Metal Forming? With regards to simulation, forging and forming are quite different. Forging requires solid FEA elements, while sheet metal forming utilizes much .

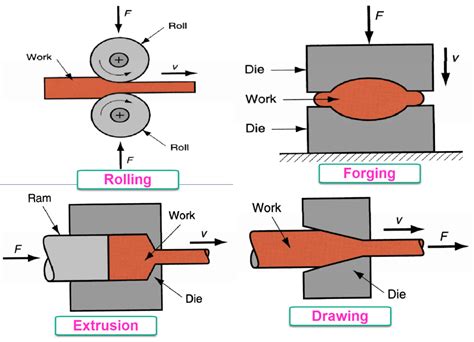

Forging and shaping are both used to change the size and shape of metal objects. The distinction between forging and forming is that forging uses pressured blows to shape metal workpieces, whereas forming uses . Metal punching, extrusion, press braking, rolling, forging and laser cutting are some of the more common forming processes. Here are more details on each technique: Common Types of Forming. The most common metal . Metal-forming process can be classified into bulk and sheet metal forming. The bulk metal forming includes forging, rolling, extrusion, and wire-drawing processes, while shearing, . #2. Sheet metal forming. Sheet metal forming involves the application of tensile and shears forces to fabricate sheets, plates, and strips to a desired possible shape using a set of tools. The punch and die are used as .

How does sheet-metal forming differ from rolling, forging, and extrusion? Sheet metal forming is usually done at room temperature. Instead of forcing the metal to flow into a new shape, as in rolling, forging, and extruding, sheet metal forming involves causing plastic deformation in the overall material without much change to its thickness or .Instead of forcing the metal to flow into a new shape, as in rolling, forging, and extruding, sheet metal forming involves causing plastic deformation in the overall material without much change to its thickness or grain structure. Sheet metal forming is usually done at room temperature. Both forging and forming are designed to manipulate the size and/or shape of metal workpieces. The difference between them is that forging involves the use of pressurized blows to deform metal workpieces, while forming involves the use of mechanical deformation.How does sheet-metal forming differ from rolling, forging, and extrusion? Punching is used to create holes or features in metal sheets and blanching is used to cut out the blanks or shapes from the metal sheets. Describe the characteristics of sheet metals that are important in sheet-forming operations. Explain why they are important.

can you use a junction box to extend power wire

.describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges ObjectivesHow Does the Simulation Process Differ Between Sheet Metal Forging and Sheet Metal Forming? With regards to simulation, forging and forming are quite different. Forging requires solid FEA elements, while sheet metal forming utilizes much more . Forging and shaping are both used to change the size and shape of metal objects. The distinction between forging and forming is that forging uses pressured blows to shape metal workpieces, whereas forming uses mechanical deformation .

Metal punching, extrusion, press braking, rolling, forging and laser cutting are some of the more common forming processes. Here are more details on each technique: Common Types of Forming. The most common metal . Metal-forming process can be classified into bulk and sheet metal forming. The bulk metal forming includes forging, rolling, extrusion, and wire-drawing processes, while shearing, punching, blanking, bending, and deep drawing techniques . #2. Sheet metal forming. Sheet metal forming involves the application of tensile and shears forces to fabricate sheets, plates, and strips to a desired possible shape using a set of tools. The punch and die are used as tools in the fabrication process.

How does sheet-metal forming differ from rolling, forging, and extrusion? Sheet metal forming is usually done at room temperature. Instead of forcing the metal to flow into a new shape, as in rolling, forging, and extruding, sheet metal forming involves causing plastic deformation in the overall material without much change to its thickness or .

Instead of forcing the metal to flow into a new shape, as in rolling, forging, and extruding, sheet metal forming involves causing plastic deformation in the overall material without much change to its thickness or grain structure. Sheet metal forming is usually done at room temperature. Both forging and forming are designed to manipulate the size and/or shape of metal workpieces. The difference between them is that forging involves the use of pressurized blows to deform metal workpieces, while forming involves the use of mechanical deformation.How does sheet-metal forming differ from rolling, forging, and extrusion? Punching is used to create holes or features in metal sheets and blanching is used to cut out the blanks or shapes from the metal sheets. Describe the characteristics of sheet metals that are important in sheet-forming operations. Explain why they are important..describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges Objectives

How Does the Simulation Process Differ Between Sheet Metal Forging and Sheet Metal Forming? With regards to simulation, forging and forming are quite different. Forging requires solid FEA elements, while sheet metal forming utilizes much more . Forging and shaping are both used to change the size and shape of metal objects. The distinction between forging and forming is that forging uses pressured blows to shape metal workpieces, whereas forming uses mechanical deformation . Metal punching, extrusion, press braking, rolling, forging and laser cutting are some of the more common forming processes. Here are more details on each technique: Common Types of Forming. The most common metal .

what is forming in metalworking

sheet metal forming techniques

Metal-forming process can be classified into bulk and sheet metal forming. The bulk metal forming includes forging, rolling, extrusion, and wire-drawing processes, while shearing, punching, blanking, bending, and deep drawing techniques .

can you wire electrical outlets just by using junction boxes

Use a metal electrical box when metal-sheathed cable (also called armored BX cable) or metal conduit is running in or out of the box. Metal cable and conduit depend on the contact from its metal sheathing to the metal box .

2 how do sheet metal forming processes differ from forging|sheet metal forming techniques