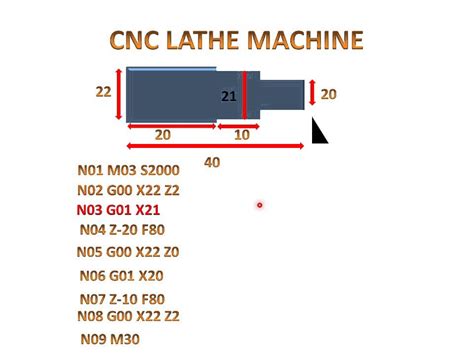

cnc lathe part programming examples A typical CNC program has (3) parts: 1) Preparation: This portion of the program selects the work and tool offsets, selects the cutting tool, turns on the coolant, sets spindle speed, and selects absolute or incremental positioning for axis . Consider using a polyurethane adhesive for bonding metal to fabric, as it provides resilience and flexibility to withstand movement and stress. When bonding metal to fabric, it's crucial to use fabric-friendly bonding .

0 · sample cnc program for turning

1 · cnc turning program examples pdf

2 · cnc programming examples with drawing

3 · cnc programming examples pdf

4 · cnc lathe sample program

5 · cnc lathe programming pdf

6 · cnc lathe programming manual

7 · cnc lathe programming for beginners

My metal detector goes crazy when I put it over this circular concrete slab and there's more concrete underneath. In the third picture the corner sticking out underneath the piece with the holes in it is another rectangular slab going under the rest of the concrete. Can anyone help me identify this? Thanks.

A typical CNC program has (3) parts: 1) Preparation: This portion of the program selects the work and tool offsets, selects the cutting tool, turns on the coolant, sets spindle speed, and selects absolute or incremental positioning for axis .This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by .

CNC Lathe Programming for Turning. CNCCookbook’s G-Code Tutorial: Learning g code the easy way. CNC Lathe Axes; Diameter Versus .

limpieza de brackets metalicos

This C-Axis Lathe Programming Example controls the main spindle with C-Axis commands, but the same program example which uses Spindle Orientation .Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment. How to program CNC machine? Here we bring CNC lathe programming examples, cycle programs, and tips for CNC turning programming.Part Programming Methods [RETURN TO T.O.C.] There are three ways to program CNC machines: CAM (computer aided manufacturing), conversational (subroutine library), or manually hand writing G&M (geometry and .

This programming workbook provides basic principles necessary to program the Haas lathe. It is not intended as an in-depth study of all ranges of the machine use. More training and information are necessary before attempting to program the machine.

sample cnc program for turning

A typical CNC program has (3) parts: 1) Preparation: This portion of the program selects the work and tool offsets, selects the cutting tool, turns on the coolant, sets spindle speed, and selects absolute or incremental positioning for axis motion.This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.

CNC Lathe Programming for Turning. CNCCookbook’s G-Code Tutorial: Learning g code the easy way. CNC Lathe Axes; Diameter Versus Radius Mode; Basic G01 and G02/03 Moves: Lines and Arcs Part Zero on CNC Turning Programs; Tool Changes and Tool Selection on the CNC Lathe; Automatic Chamfer and Corner Rounding with G01. See Also. Speed and .This C-Axis Lathe Programming Example controls the main spindle with C-Axis commands, but the same program example which uses Spindle Orientation M19 can be found here also.

Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment.

How to program CNC machine? Here we bring CNC lathe programming examples, cycle programs, and tips for CNC turning programming.Part Programming Methods [RETURN TO T.O.C.] There are three ways to program CNC machines: CAM (computer aided manufacturing), conversational (subroutine library), or manually hand writing G&M (geometry and miscellaneous) code.

From simple components to complex designs, CNC turning lathe programming has revolutionized the manufacturing process. In this blog post, we will provide a comprehensive guide on CNC turning lathe programming, complete with a practical programming example. Section 1: Understanding CNC Turning Lathe Programming

With written program examples to make learning to program easy. In this course we will be learning the basics of programming a 2-Axis CNC Lathe. We will be covering topics such as: Canned Cycles: I will explain in detail about each cycle breaking down every part of the program.This programming workbook provides basic principles necessary to program the Haas lathe. It is not intended as an in-depth study of all ranges of the machine use. More training and information are necessary before attempting to program the machine.A typical CNC program has (3) parts: 1) Preparation: This portion of the program selects the work and tool offsets, selects the cutting tool, turns on the coolant, sets spindle speed, and selects absolute or incremental positioning for axis motion.

This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability. CNC Lathe Programming for Turning. CNCCookbook’s G-Code Tutorial: Learning g code the easy way. CNC Lathe Axes; Diameter Versus Radius Mode; Basic G01 and G02/03 Moves: Lines and Arcs Part Zero on CNC Turning Programs; Tool Changes and Tool Selection on the CNC Lathe; Automatic Chamfer and Corner Rounding with G01. See Also. Speed and .

light without junction box

This C-Axis Lathe Programming Example controls the main spindle with C-Axis commands, but the same program example which uses Spindle Orientation M19 can be found here also.Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment. How to program CNC machine? Here we bring CNC lathe programming examples, cycle programs, and tips for CNC turning programming.Part Programming Methods [RETURN TO T.O.C.] There are three ways to program CNC machines: CAM (computer aided manufacturing), conversational (subroutine library), or manually hand writing G&M (geometry and miscellaneous) code.

From simple components to complex designs, CNC turning lathe programming has revolutionized the manufacturing process. In this blog post, we will provide a comprehensive guide on CNC turning lathe programming, complete with a practical programming example. Section 1: Understanding CNC Turning Lathe Programming

cnc turning program examples pdf

cnc programming examples with drawing

lightweight sheet metal

cnc programming examples pdf

Your home’s main electrical service panel was once called a fuse box because it contained all the main fuses for different electrical circuits throughout the house. Today, however, a service panel is often called a “breaker box” because it’s full of circuit breakers, which are safer and more convenient than fuses.

cnc lathe part programming examples|cnc programming examples pdf