efficient metal enclosure fabrication In this comprehensive guide, we will explore the world of custom enclosures, including their benefits, types, materials, design considerations, fabrication techniques, finishing options, manufacturers, cost considerations, . $23.91

0 · sheet metal enclosures

1 · sheet metal enclosure fabrication

2 · sheet metal enclosure design

3 · sheet metal cabinet design

4 · sheet metal box design guide

5 · metal enclosure box sizes

6 · metal enclosure box for electronics

7 · metal box for electronics projects

Noteworthy farmhouse design elements include: White Siding; Multicolor Dark Grey Roof; Covered Porch; Rich Brown Garage Doors Doors #6) Light & Bright White Farmhouse Exterior. Source: Nikki’s Plate. This stunning .

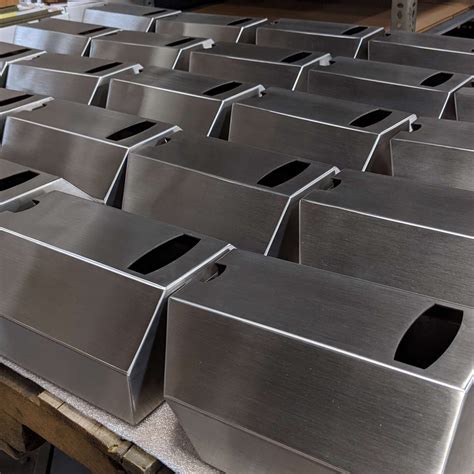

Our equipment utilizes a superior and more efficient air bending technique for seamless pieces. . is committed to using the highest quality materials and advanced fabrication techniques to produce durable and reliable metal . Crafting top-quality enclosures calls on our full range of capabilities: laser cutting, punching, forming, welding, hardware installation, . In this comprehensive guide, we will explore the world of custom enclosures, including their benefits, types, materials, design considerations, fabrication techniques, finishing options, manufacturers, cost considerations, . Fabrication of custom enclosures entails a series of intricate processes, including laser cutting, CNC punching, bending, welding, and powder coating. These techniques are employed to shape and assemble enclosure .

Custom enclosures are meticulously crafted through precision sheet metal fabrication, a process that involves cutting, bending, and assembling sheet metal to create the desired enclosure structure. This method allows for . The fabrication process of sheet metal enclosures involves several key steps, from initial concept to the final product. Understanding each phase can help ensure that the finished . Designing and fabricating metal enclosures involves careful sheet metal material selection, precise measurements, mastering bending and forming techniques, and implementing effective quality control.Approved Sheet Metal (ASM) will fabricate a single expedited prototype enclosure all the way to low-volume production sheet metal quantities in the thousands. Our rapid sheet metal services utilize state-of-the-art software, seasoned .

Boyd uses sheet metal to fabricate thermally conductive enclosures and chassis, heat sinks, and liquid system components. We manufacture single stamped metal thermal . Sheet metal fabrication offers an inexpensive and efficient method of producing electronic enclosures. Normally, these metal enclosures have considerably reduced material expenses in comparison to CNC-machined types.Our equipment utilizes a superior and more efficient air bending technique for seamless pieces. . is committed to using the highest quality materials and advanced fabrication techniques to produce durable and reliable metal enclosures. Our fabrication process ensures that each enclosure meets the highest standards of quality and performance .

Crafting top-quality enclosures calls on our full range of capabilities: laser cutting, punching, forming, welding, hardware installation, assembly, finishing, color anodizing, and more. In this comprehensive guide, we will explore the world of custom enclosures, including their benefits, types, materials, design considerations, fabrication techniques, finishing options, manufacturers, cost considerations, and future trends. Fabrication of custom enclosures entails a series of intricate processes, including laser cutting, CNC punching, bending, welding, and powder coating. These techniques are employed to shape and assemble enclosure components with utmost accuracy, maintaining structural integrity and aesthetic appeal throughout the fabrication process.

Custom enclosures are meticulously crafted through precision sheet metal fabrication, a process that involves cutting, bending, and assembling sheet metal to create the desired enclosure structure. This method allows for the creation of intricate and customized designs to meet specific requirements. The fabrication process of sheet metal enclosures involves several key steps, from initial concept to the final product. Understanding each phase can help ensure that the finished enclosure meets all technical specifications and quality standards. Designing and fabricating metal enclosures involves careful sheet metal material selection, precise measurements, mastering bending and forming techniques, and implementing effective quality control.Approved Sheet Metal (ASM) will fabricate a single expedited prototype enclosure all the way to low-volume production sheet metal quantities in the thousands. Our rapid sheet metal services utilize state-of-the-art software, seasoned employees, and top-of-the-line equipment to get parts out the door fast and right the first time.

sheet metal enclosures

Boyd uses sheet metal to fabricate thermally conductive enclosures and chassis, heat sinks, and liquid system components. We manufacture single stamped metal thermal conductors, bent metal thermally conductive components, and complex sheet metal assemblies with integrated advanced liquid or air cooling technologies . Sheet metal fabrication offers an inexpensive and efficient method of producing electronic enclosures. Normally, these metal enclosures have considerably reduced material expenses in comparison to CNC-machined types.Our equipment utilizes a superior and more efficient air bending technique for seamless pieces. . is committed to using the highest quality materials and advanced fabrication techniques to produce durable and reliable metal enclosures. Our fabrication process ensures that each enclosure meets the highest standards of quality and performance . Crafting top-quality enclosures calls on our full range of capabilities: laser cutting, punching, forming, welding, hardware installation, assembly, finishing, color anodizing, and more.

In this comprehensive guide, we will explore the world of custom enclosures, including their benefits, types, materials, design considerations, fabrication techniques, finishing options, manufacturers, cost considerations, and future trends.

Fabrication of custom enclosures entails a series of intricate processes, including laser cutting, CNC punching, bending, welding, and powder coating. These techniques are employed to shape and assemble enclosure components with utmost accuracy, maintaining structural integrity and aesthetic appeal throughout the fabrication process.

Custom enclosures are meticulously crafted through precision sheet metal fabrication, a process that involves cutting, bending, and assembling sheet metal to create the desired enclosure structure. This method allows for the creation of intricate and customized designs to meet specific requirements. The fabrication process of sheet metal enclosures involves several key steps, from initial concept to the final product. Understanding each phase can help ensure that the finished enclosure meets all technical specifications and quality standards.

Designing and fabricating metal enclosures involves careful sheet metal material selection, precise measurements, mastering bending and forming techniques, and implementing effective quality control.Approved Sheet Metal (ASM) will fabricate a single expedited prototype enclosure all the way to low-volume production sheet metal quantities in the thousands. Our rapid sheet metal services utilize state-of-the-art software, seasoned employees, and top-of-the-line equipment to get parts out the door fast and right the first time.

metal grill for window side panel at house

sheet metal enclosure fabrication

Detract from the heavy look of oak cabinets by opting for lighter tones in other areas of your kitchen. To brighten a space, use white or light-colored walls, flooring, and countertops. Shiny surfaces, including glass tile and stainless-steel appliances, can also reflect light and give the room a

efficient metal enclosure fabrication|metal box for electronics projects