how to extend junction boxes For instance, the best way to conceal such a junction box is to use a large, deep 4 . There are some tips you need to know in order to produce high-quality results while welding automotive sheet metal successfully. The first step to successful welding is to understand the metal you are working with. If you don’t, you will .

0 · wiring a junction box diagram

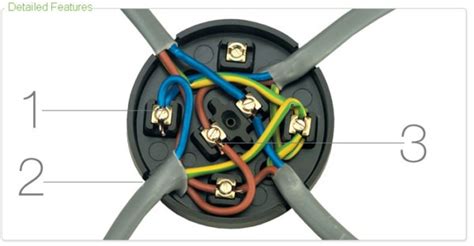

1 · terminal junction box wiring guide

2 · junction box wiring problems

3 · junction box wiring instructions

4 · electrical junction box instructions

5 · connecting wires in junction box

6 · 6 terminal junction box wiring

7 · 3 terminal junction box wiring

My little mig welder has left a few pin holes in my sheet metal repair. What is good to fill these in with before laying filler over it? I've heard bondo glass is good, and I've heard just seam sealer will work.

You will need to reroute these cables to a different junction box somewhere the wiring is able reach with the needed spare length inside the box. From there, you can run a /2 w/ground cable to this location, e.g. NM or MC.For instance, the best way to conceal such a junction box is to use a large, deep 4 .You can get extension boxes (that size box with an open back designed to stack on . For instance, the best way to conceal such a junction box is to use a large, deep 4-11/16" square metal box (which you need for the cubic inches), .

You can use a junction box to extend wiring. First, turn off your power at the main breaker. Next, cut openings and fit the wires through the box. Once the wires are connected, . You can get extension boxes (that size box with an open back designed to stack on an existing box). The deeper 4 x 4 x 2.125" box is 30 . Unlock the power of electrical box extenders with our step-by-step guide, showing you how to properly install and use them to bring your electrical outlets up to code and ensure . An electrical box extender. Box extenders are inexpensive, easy to install and — best of all — they bring your electrical installation up to code. Flush-mounted devices like receptacles and switches can only have a 1/4-inch gap .

If you must extend it, i would try to hide it from public view so someone doesn't disconnect it. There's nothing like going in after someone else's work to try and diagnose a problem only to find there's a junction box that someone was in there screwing . In addition, if you decide to splice some wires together, you have to make sure you have junction boxes available.These come in various shapes and sizes, so you have to think about completing the project. Then, you should . The most common colors are blue, gray and white, depending on the brand. Metal box extenders also exist, but if the box in your wall is plastic, which is likely in residential wiring, use a plastic (PVC) extender. Box extenders come in “single-gang,” which means the box holds one device only, as well as two-gang and multiple-gang. Some .

Installing a Tyco Electronics no junction box splice connector.https://www.grainger.com/category/electrical/electrical-supplies/wire-connectors/non-metallic-. Those outlets are likely much higher on the wall than you will want height wise in a finished space, extending the wire is not an option unless you leave accessible junction boxes. Supply-wise you can only really reside the outlet(if they didn’t use backstabs), but you need a different style box and plate. Junction boxes need to be accessible and not covered up with drywall etc. This is a reason I do not like the NM splice kits as they are buried in the wall. I still don't see how they got approved in the first place. . Extend the wires within the box with Ideal Splice line push- in wire connectors #30-1342S the wire as usual.

Proper box size ensures wires have room to dissipate heat. Keeping junction boxes from being overfilled is critical. 4. Mount the Box Securely. Install the box in the desired wall location, leaving at least 6" of free wire to make splices and connections. Secure the box to framing members according to manufacturer specifications. In this video I show you numerous ways to fix wires that are too short in an electrical box. This one of the most common mistakes when running electrical wi.Technically, by code, any connections have to be made inside an approved junction box--you can't just splice a piece of wire where you need it. And the wire you use depends on the size/type of wire that you're connecting to. . Use a tyco Romex splice kit to extend the wire and avoid adding a junction box. Reply reply SpiritedConfidence47 . http://www.VideoJoeKnows.com How to install an electrical extension box is easy.when you know how. Why would youneed to use an extension box for your ele.

wiring a junction box diagram

In this video, I show you an electrical box extender installation. A PVC outlet box extenders are very simple to use. My Favorite Tools And Supplies 👉 https. Yes of course. All the usual rules for junctions and splices are in play. The box needs to be of an adequate size and type, the box must be readily accessible, the type of splice must be correct and of the correct sized wire and type, etc etc. But there is nothing in particular that is wrong with having a junction box for a 30A 240V circuit. The common 99 cent 4x4x1.5" box is 21 cubic inches per the rules. You can get extension boxes (that size box with an open back designed to stack on an existing box). The deeper 4 x 4 x 2.125" box is 30 cubic inches. The larger 4-11/16" (120mm) square box is 42 cubic inches* They also make 6x6 boxes that are enormous, obviously. However, the existing Romex is too short to comfortably be threaded through a hole in the stud/shim and into the fan box on the other side. I was going to leave the old box in place, using it as a pure junction box (no fixture/switch/outlet) and running a short length of Romex from this box, through the stud/shim, to the fan box on the other side.

Extend the conduit and pull new longer wires from the closest upstream junction box. Add a junction box at the end of the conduit and extend with additional conduit and new wires from that box. Note that any junction .

In case you want two switches or two outlets in place of a single-gang switch or outlet, this is how to you install a dual gang box in place of a single gang.

NM-B 14/2 Wiring Connections in Wiremold Junction Box. Fold the wires and install the Wiremold BW35 junction box with the two included screws. The junction box will be closed with a standard blank wall plate cover to .I've seen them on the side of surface-mount breaker boxes. Mine used to be affixed to the side of the junction box for the light in my mechanical room. Reply reply more reply. more reply . That failing, pig tail with the exact same type wire to extend it. (LVT) Watch a YouTube video for a visual but basically get a good 12” of length for .

the screws allow you to adjust the box, even after you mount it. ![Screw on "smart box" style][1] To remove the existing box just cut the nails off with a hacksaw blade. Slide the old box off and replace with the above box. As Niall said for what you want an old work box, also called a cut in box or tiger grip box can easily be used. Wire that short can't be spliced or extended. The wire must be able to come out beyond the surface of the box at least 3". You will need to reroute these cables to a different junction box somewhere the wiring is able reach with the needed spare length inside the box. From there, you can run a /2 w/ground cable to this location, e.g. NM or MC.

Bob Schmidt shows you how to use an electrical box extension with standard plastic electrical boxes, during remodeling. When adding drywall, tile, wood over.

How to wire an electrical junction box. A junction box is used to add a spur or to extend circuits and direct power to lights and additional sockets. Advice on wiring electrical junction box with easy to follow junction box wiring diagrams, including information on 20 and 30 amp junction boxes. . Step 4 – Fix and Close Junction Box: Once .

The cable sheathing (outer jacket) should extend 1/4 to 1/2 inch into the box beyond the clamp, and the individual conducting wires should extend about 6 inches into the box. If necessary, trim the wires as needed and strip 3/4 inch of insulation from the end of each wire, using wire strippers. It has always been my understanding that only 1-extension box or ring can be added to an existing box to increase it's volume. However in Art.314 I can not seem to locate anything on this. Recently I've come across some newer installations that have 2 rings or more added onto a preexisting 4x4x1.5" work box. And mark the position of where to put the junction box. What you’re going to do is, push the tape in both left and right. Then mark the place where it hits a dead end. You’ll find two spaces, one for the spur and the other to place the box. Trace And Cut Spaces For Junction Box And Spur . Now, put the junction box on the marked spot on the .

The wall where it was on before has been removed. I am looking to install now the baseboard heater on an adjacent wall. Originally, it's a separate cable run to sustain the necessary power for this heater . Can i use a junction box and extend that cable to another wall? Really would appreciate an answer on this. Thanks EdLogically I can use 2, 3 terminal junction boxes, or a single 6 terminal junction box to extend a ring main (inserting a loop to the new socket(s) I am installing). However are there any practical issues with a 6 terminal junction box – e.g. space for the cables? What would anyone inspecting the wiring expect to see?

desktop cnc metal engraving machine

terminal junction box wiring guide

In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and weld it in. I demonstrated this.We are going to show you how to weld sheet metal that is rusted out and in bad shape. This is very common in the welding restoration of old cars and tractors. Today's weld project is a.

how to extend junction boxes|connecting wires in junction box