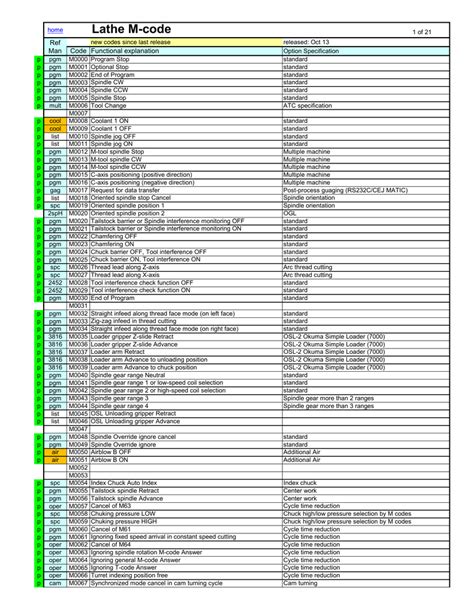

cnc machine language m-code list Dive into our M-Code Cheat Sheet to understand CNC machine functions. From spindle control to tool changes, explore common and manufacturer-specific M-Codes.

This innovative box spring is constructed with a strong metal frame that provides exceptional support and durability for your mattress. Not only is the ZINUS Smart Box Spring built to last, but it also features easy assembly, making set-up a breeze.

0 · printable m code list

1 · m codes cnc milling

2 · fanuc m code list pdf

3 · fanuc m code list

4 · fanuc cnc g code and m code list pdf

5 · complete list of m codes

6 · cnc m code list pdf

7 · cnc m code chart

If you're looking to achieve high-octane leads, searing trem-picked distortion, or in-your-face chunk, the Box of Metal Vexter will get you there and have your singer running for the hills.

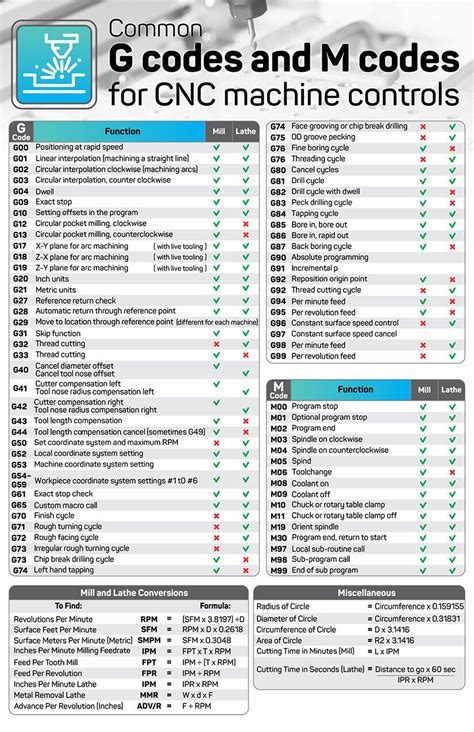

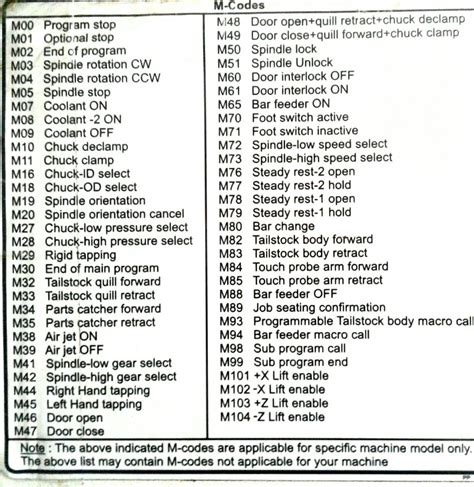

G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow. In this article, we will navigate through the complexities of CNC programming by offering a detailed G-Code and M-Code reference.

CNC G-codes & M Codes for milling and turning with explanations, . Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the .

I explore a complete of CNC M Codes and look at their function and how we use them on both CNC lathes and CNC milling machines. Dive into our M-Code Cheat Sheet to understand CNC machine functions. From spindle control to tool changes, explore common and manufacturer-specific M-Codes.Multi-chapter guide to M-Code describing: what is M-Code for CNC machining, M Code vs. G Code, Benefts of M Code, Commands, FAQ's, reference list, and more.Learn everything about G-code and M-code, essential languages for CNC machine operations. Our comprehensive guide covers basic structures, common commands, examples, and the role of AI in CNC programming.

G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow.

In CNC machining, M codes are used to control machine and miscellaneous functions. This includes turning off and on features such as the machine spindle as well as coolant functions. They also control how the CNC reads and flows through the program.

In this article, we will navigate through the complexities of CNC programming by offering a detailed G-Code and M-Code reference.CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide) To select the appropriate G-codes and M-codes for programming based on different CNC systems, a comprehensive approach considering system specifics, processing requirements, and industry best practices is essential. Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw .

I explore a complete of CNC M Codes and look at their function and how we use them on both CNC lathes and CNC milling machines. Dive into our M-Code Cheat Sheet to understand CNC machine functions. From spindle control to tool changes, explore common and manufacturer-specific M-Codes.Multi-chapter guide to M-Code describing: what is M-Code for CNC machining, M Code vs. G Code, Benefts of M Code, Commands, FAQ's, reference list, and more.

printable m code list

m codes cnc milling

fanuc m code list pdf

fanuc m code list

fanuc cnc g code and m code list pdf

A Dirichlet distribution of three dimensions draws thinks like [0.2,0.4,0.4], [0.3,0.3,0.4], etc. which can be used as Categorical distributions. This is why it is used to generate distributions over $V$ words (topics), and distributions over $T$ topics.

cnc machine language m-code list|cnc m code list pdf