minimum hole distance from edge sheet metal K Factor in sheet metal bending is a constant used to calculate sheet metal . The deep wavy corrugations provide a bold aesthetic and shadow like effect. Corrugated metal sheeting is affordable and it’s easy to install. It’s perfect for both commercial and residential metal roofing and siding projects.

0 · sheet metal rib design guidelines

1 · sheet metal minimum flange length

2 · sheet metal gusset design guidelines

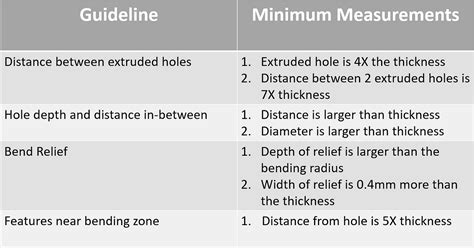

3 · sheet metal extruded hole design

4 · sheet metal design guideline pdf

5 · sheet metal corner relief chart

6 · sheet metal bending design guidelines

7 · maximum thickness sheet metal bending

WBW offer stainless steel metal fabrication and a great range of services and premium products across Victoria from Ballarat.

metal bracket for led lights

Learn how to design good sheet metal parts with minimum hole distance from bend edge and other guidelines. The recommended minimum distance is three times the sheet thickness plus bend radius.K Factor in sheet metal bending is a constant used to calculate sheet metal .

Sheet Metal gauge chart converts sheet thickness from gauge to mm or inch. . 3. The minimum distance between the hole or slot and the edge of the sheet should be three times of sheet thickness. Min. Edge-to-hole distance= 3 x thickness. 4. If the custom . Outlined below are the minimum distances to be maintained between a gusset and other features like edges and holes in sheet metal components. These guidelines are calculated considering the material .If a material is 0.036 in. (0.914mm) or thinner, the hole should be 0.062 in. (1.574mm) from the material edge; if the material is thicker than 0.036 in. (0.914mm), the hole should be at least .

metal bracket feet for coffee table

Calculating Minimum Edge Distance and Bend Distance. Selecting a hole position too close to a part’s edge or bend radius can significantly impact the performance of the final product. Fortunately, calculating a better hole . To avoid workpiece failure, DFM guidelines recommend a minimum distance (D1) from hole to the sheet edge equal to at least the plate thickness (T); we recommend a safe design zone of 1.5 to 2T. Also, when piercing multiple . When the number of holes in the two rows is not equal, two requirements must be met: 1. The hole pitch is larger, the edge distance of the two holes is greater than 2t (t is the material thickness); 2. The total number of .Certain distance should be maintained between two extruded holes in sheet metal designs. If extruded holes are too close it can lead to metal deformation. It is recommended that the minimum distance between two extruded holes should .

The distance between punched holes and the bending edge or forming features of a sheet metal part should be at least 1.5 times the thickness of the sheet metal plus the bend or forming .PEM® REF/ C/L TO EDGE APRIL 2019 SUBJECT: MINIMUM DISTANCE HOLE C/L TO EDGE The term “minimum distance hole-centerline-to-edge” is defined as the minimum distance the mounting hole centerline may be to one edge of a panel to still allow the proper clinching of a fastener into the sheet. When a fastener is close to more than one edge, the .

Welcome to Kreatorzone! On this sheet metal design series you will find the recommended Minimum Distance from Extruded Hole to Part Edge.DISCLAIMER:Do not us.Hardware to edge/hole +/- 0.010 in. +/- 0.254mm: Hardware to hardware +/- 0.015 in. +/- 0.381mm: Bend to edge +/- 0.010 in. +/- 0.254mm: . Minimum flange length on sheet metal parts must be at least 4 times the material thickness. It . Therefore, only the formulas for the minimum distances with pilot hole in accordance with DIN EN 1995-1-1: 2010-12 need to be taken into account. However, the extensive tables and representations of DIN EN 1995-1-1: 2010-12 quickly make it clear that the necessary edge distance cannot be determined without special knowledge in relation to the . 2.1 The minimum distance between two counterbore holes should be eight times the thickness of the metal sheet. 2.2 The minimum distance between a counterbore to an edge should be four times the thickness of the metal sheet. 2.3 The minimum distance between a counterbore to a bend should four times the thickness of the metal sheet + bend radius. 3.

How Far From the Edge Cut Features Should Be In Sheet Metal Parts. . Tapped hole diameter/2 + the minimum tap hole-to-edge distance for the chosen material. The minimum hole-to-edge distance for each material can be found on our Materials Page under the “Design Considerations” heading. If holes must be near the edge, they should still be at least the distance equal to the sheet thickness (T) from the edge and preferably between 1.5T and 2T from the edge.

Few simple yet integral tips which need to be taken into consideration while designing a sheet metal part are-Minimum Hole Diameter. Holes are a commonly used feature in a sheet metal part. Small holes in sheet metal can be punched or can be laser cut, depending on the equipment used for punching. . L= Bend Edge to Relief Edge Distance. Hole .

Minimum bend radius. . such as louvers or extruded holes, you will need to increase the distance relative to bends and edges in order to prevent malformed features and sheet deformation. . Sheet metal hems are features where the edge of a sheet metal part is folded back onto itself. In addition to increasing material stiffness locally, they .B = Minimum distance from a burring hole edge and the part edge t = Sheet metal thickness . . D = Minimum distance from a burring hole edge and cutout edge t = Sheet metal thickness . A DEFINITIVE GUIDE TO DESIGN FOR MANUFACTURING SUCCESS 11 Burring Hole Spacing Sufficient, space should be mentioned between the two adjacent burring holes to . We’d need to calculate 0.209”/2 + 0.063” to find the minimum distance from the center of the tapped holes to the nearest cut feature.. The minimum distance for a 1/4-20 tap in 0.125” 5052 aluminum is 0.167”.. Then, measure the distance from the center of the hole to be tapped to the nearest cut edge.The minimum hole-to-edge distance is measured from the edge of the tapped hole to the nearest cut feature, and the specification can be found on each individual material info page by stock thickness. Below is a chart of SendCutSend’s available tap sizes. Each tap size is paired with the required through-hole size that will be needed in your .

When the number of holes in the two rows is not equal, two requirements must be met: 1. The hole pitch is larger, the edge distance of the two holes is greater than 2t (t is the material thickness); 2. The total number of rows should be evenly arranged. , .Minimum recommended hole edge from bend face = 2.5T + R; Minimum recommended slot edge from bend face = 4T + R . 2. Holes and slots positioned too close to edge. Holes and slots located too near a part edge can result in a ‘bulging’ effect. Therefore, a good rule of thumb is to leave a minimum space of at least 2 times the thickness of the .what drill bit is used to cut holes for 1/8 diameter rivet. 3. The general rule for transverse pitch in unlimited overlap is? 4. What is the minimum bend radius of a sheet metal? Don't know? Terms in this set (51) The limits for pitch in three rows or more are? . What are the limits for edge distance with a MS20426AD4-5 rivet?

Study with Quizlet and memorize flashcards containing terms like What is the name given to the perpendicular distance between rivet rows?, What is the name given to the distance between the centers of the adjacent rivets in the same row?, Wha are the rules for minimum and maximum edge distance? and more. How close to the edge can you get in aluminum before a clearance hole starts to tear through the side? The hole will be around #27 or 0.144. How close to the edge can you get in stainless for a threaded hole? I only have .

The following formula calculates the minimum distance from the bend at which you can punch or cut a hole, Distance (D) = Sheet Metal Thickness (t) + Bend Radius (ir) + Diameter of The Hole. So, from the formula, it is clear that the distance is proportional to the sheet metal thickness, bend radius and diameter of the hole. Minimum distance between the hole and the oblong hole. . it is crucial to ensure that the distance between the hole edge and the bend line is greater than the minimum hole margin specified in Table 1-14. Additionally, the bend radius can be found in Table 1-9. . This article demystifies the crucial role of fabrication holes in sheet metal . Fig.: Bending specs for 0.040” 5052 Aluminum. Bend Length. The bend length, or width of the flange, is dependent on, wait for it, the material properties: For the 304 Stainless in the previous example, the maximum length is 36” while a thinner, more ductile material like the the 5052 aluminum can easily be bent all the way up to the max part size of 44”.

Hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. For tear drop hems, the inside diameter should be equal to the material thickness. . For holes, the minimum distance between the hole’s edge is 2 times the material thickness plus the hem’s radius. For bends, the minimum distance . The minimum distance that holes should be placed from a bend is a function of the material thickness, bend radius, and the hole’s diameter. Holes should be at least 2.5 times the material .

sheet metal rib design guidelines

L Bending. 1) Factors determining the minimum L bending. As the middle of the press brake V groove is hollow, when forming, the edge fold must be longer than the hollow section and the specific landing edge size varies in the production of different companies (the lower section of V groove is under use for a long time, the R angle increases, which makes the .The distance will be a function of the load applied by whatever is secured by that thread. If the load is effectively negligible, then the positioning can be as close as possible without the cut threads breaking through the wall.For open hems, minimum inside diameter is equal to the . Hole-to-edge distance Slot-to-bend distance Slot-to-edge distance SHEET METAL GUIDE V2.2 — TOLERANCES. Notches & Tabs DIMENSIONS The minimum thickness a notch must maintain is at least 0.04” (1mm) or the material’s thickness, whichever .

Welcome to Kreatorzone! On this sheet metal design series you will find the recommended Minimum Distance between Extruded HolesHit that like button and share.When punch holes are not parallel to each other or the edge, the spacing between holes or the distance from the hole to the edge should be at least equal to the sheet metal thickness, i.e., B ≥ T, as shown in Figure 2. If the holes are parallel, the spacing should be at least 1.5 times the thickness, i.e., C ≥ 1.5T.

sheet metal minimum flange length

sheet metal gusset design guidelines

House Call is a quest in We Happy Few. It takes place in the Parade District and is unlocked upon reaching the only open checkpoint to the Wellington Health Institute on The Gravel Walk.

minimum hole distance from edge sheet metal|sheet metal bending design guidelines