cnc machine shop labor rates There’s a few different ranges of numbers, and as a general rule, you get what you pay for. $40-55/hour is considered cheap in the manufacturing industry, and while you may be . Great sleeveless sweater for under a light jacket at work or an evening out Metallic thread woven into the cable knit Figure flattering design Small

0 · machinery cost per hour calculator

1 · machine shop hourly rate calculator

2 · machine rigging cost per hour

3 · cnc router cost per hour

4 · cnc milling cost per hour

5 · cnc machine hourly rate calculator

6 · cnc machine cost per hour

7 · calculating machine cost per hour

Make your mark with Ore Metals’ precious metal sheets, available in a variety of types and sizes for infinite design scope. Our lustrous sterling silver and yellow gold sheeting are the ideal base for your jewellery making designs. It’s no surprise they’re a runaway bestseller!

Anyone have experience quoting machining work, specifically large parts that are 12ft long and weigh several thousand pounds? Through some seridipitous . The CNC Machine Hourly Rate Calculator is an essential tool for accurately estimating costs in CNC machining. By inputting relevant data, shops can determine the total cost of ownership and the final hourly cost with labor.

In this article, we calculate hourly rate by summing all our monthly costs and dividing by the number of machinist hours worked. I’ve chosen a shop of 9 staff consisting of 5 machinists and 4 support staff. I’ve estimated costs as best I . There’s a few different ranges of numbers, and as a general rule, you get what you pay for. -55/hour is considered cheap in the manufacturing industry, and while you may be .

What you need to do is combine the Hourly Rate on a per machine basis with your estimate of how many hours will actually be needed from each machine. G-Wizard Estimator helps you build a simple spreadsheet to do this. Shop rate should be adjusted to each piece of equipment and their production rate and what not. If you had to buy a brand new 0-500K horizontal today, /hr for 40hr/week .

Since many shops will utilize an hourly rate as a basis for charging for machining time, this post is dedicated to some helpful guidelines on how to calculate that machining hourly rate. Below are some points we consider important when .Anyone have experience quoting machining work, specifically large parts that are 12ft long and weigh several thousand pounds? Through some seridipitous events I may have to figure out how much I should charge for my labor to run a one-off at my shop that would be "on the side."

The CNC Machine Hourly Rate Calculator is an essential tool for accurately estimating costs in CNC machining. By inputting relevant data, shops can determine the total cost of ownership and the final hourly cost with labor.

In this article, we calculate hourly rate by summing all our monthly costs and dividing by the number of machinist hours worked. I’ve chosen a shop of 9 staff consisting of 5 machinists and 4 support staff. I’ve estimated costs as best I could. Some values could be argued as too low or too high, but the idea is the same. The plan is as follows: If you added your labor up and came in with a total of 15hrs at a rate of 30hr so a total of 0 in labor. Materials/cost of goods came in around 5. Making a total of 5 dollars in labor and cost of goods. There’s a few different ranges of numbers, and as a general rule, you get what you pay for. -55/hour is considered cheap in the manufacturing industry, and while you may be able to find a local shop that has a rate that low, their work will probably reflect. What you need to do is combine the Hourly Rate on a per machine basis with your estimate of how many hours will actually be needed from each machine. G-Wizard Estimator helps you build a simple spreadsheet to do this.

Shop rate should be adjusted to each piece of equipment and their production rate and what not. If you had to buy a brand new 0-500K horizontal today, /hr for 40hr/week would not pay the term and tooling.

cheapest make custom metal parts

machinery cost per hour calculator

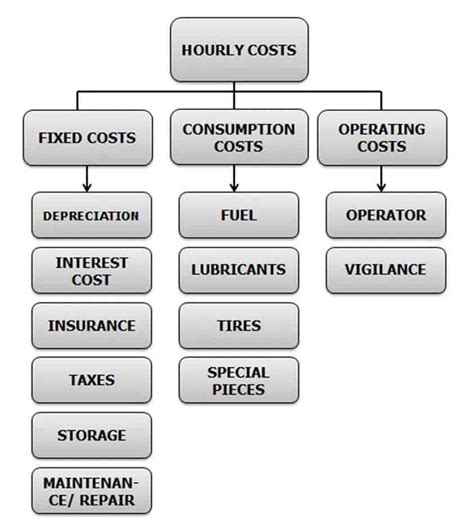

Since many shops will utilize an hourly rate as a basis for charging for machining time, this post is dedicated to some helpful guidelines on how to calculate that machining hourly rate. Below are some points we consider important when calculating the hourly rate for a particular machine. To calculate CNC machining cost per hour effectively, consider several key factors: machine depreciation, operator wages, overhead expenses, tooling costs, and material expenses. Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours.

According to a recent survey by Practical Machinist, the average hourly rate for a CNC machine is around . However, rates can range from to per hour, depending on the factors above.Anyone have experience quoting machining work, specifically large parts that are 12ft long and weigh several thousand pounds? Through some seridipitous events I may have to figure out how much I should charge for my labor to run a one-off at my shop that would be "on the side." The CNC Machine Hourly Rate Calculator is an essential tool for accurately estimating costs in CNC machining. By inputting relevant data, shops can determine the total cost of ownership and the final hourly cost with labor.

In this article, we calculate hourly rate by summing all our monthly costs and dividing by the number of machinist hours worked. I’ve chosen a shop of 9 staff consisting of 5 machinists and 4 support staff. I’ve estimated costs as best I could. Some values could be argued as too low or too high, but the idea is the same. The plan is as follows:

If you added your labor up and came in with a total of 15hrs at a rate of 30hr so a total of 0 in labor. Materials/cost of goods came in around 5. Making a total of 5 dollars in labor and cost of goods. There’s a few different ranges of numbers, and as a general rule, you get what you pay for. -55/hour is considered cheap in the manufacturing industry, and while you may be able to find a local shop that has a rate that low, their work will probably reflect. What you need to do is combine the Hourly Rate on a per machine basis with your estimate of how many hours will actually be needed from each machine. G-Wizard Estimator helps you build a simple spreadsheet to do this.

Shop rate should be adjusted to each piece of equipment and their production rate and what not. If you had to buy a brand new 0-500K horizontal today, /hr for 40hr/week would not pay the term and tooling.Since many shops will utilize an hourly rate as a basis for charging for machining time, this post is dedicated to some helpful guidelines on how to calculate that machining hourly rate. Below are some points we consider important when calculating the hourly rate for a particular machine.

To calculate CNC machining cost per hour effectively, consider several key factors: machine depreciation, operator wages, overhead expenses, tooling costs, and material expenses. Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours.

machine shop hourly rate calculator

chemical resistant junction box

Shop Women's White House Black Market Black Gold Size XS Sweaters at a discounted price at Poshmark. Description: WHBM Sparkly Metallic Stripe Print Sweater Features Colors in Black, .

cnc machine shop labor rates|cnc machine cost per hour