cnc lathe machine programming pdf This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by . For example, 18-gauge sheet metal would be 0.040 inches thick if made from aluminum and 0.048 inches thick if made from stainless steel. That’s why it is important to ensure you use the right conversion chart for the given piece of sheet metal.

0 · haas lathe programming workbook PDF

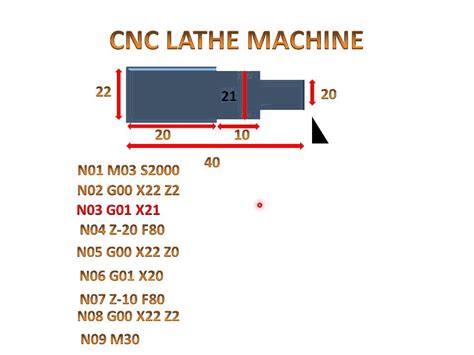

1 · cnc turning program examples PDF

2 · cnc turning machine programming PDF

3 · cnc turning cycle program PDF

4 · cnc programming manual PDF

5 · cnc programming examples PDF

6 · cnc lathe programming example PDF

7 · cnc lathe manual PDF

Our Junction Box Sizing Calculator is an invaluable tool for electricians, contractors, and DIY enthusiasts. It helps determine the appropriate size of a junction box needed to safely house electrical connections. This calculator is designed for use in various construction projects, whether residential, commercial, or industrial.Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.This course describes the basic knowledge of CNC Lathe machining program and how to use the common instructions to the CNC control. The goal of this course is to help you to be able to .

Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment.This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by .Welcome to Productivity, Inc., your local Haas Factory Outlet (H.F.O.) for the Haas Lathe Programming Class. This class is intended to give a basic understanding of the set-up and .

The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming .2-1-1 Program Reference Point and Coordinate Values For a CNC lathe, coordinate axes X and Z are set on the machine and their intersecting point is called a “program reference point”. The X .To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. .This file is the Adobe Acrobat version of Denford G and M Programming for CNC Lathes. File Optimisation: On-screen display and printing. Graphics: resampled to 600 dpi.

This programming workbook provides basic principles necessary to program the Haas lathe. It is not intended as an in-depth study of all ranges of the machine use. Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.

This course describes the basic knowledge of CNC Lathe machining program and how to use the common instructions to the CNC control. The goal of this course is to help you to be able to prepare the basic machining program with referring the .Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment.This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.

Welcome to Productivity, Inc., your local Haas Factory Outlet (H.F.O.) for the Haas Lathe Programming Class. This class is intended to give a basic understanding of the set-up and operation of a Haas Turning Center.The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming examples are used to explain the commands and statements, which are also defined according to DIN 66025. 2. Work preparation

2-1-1 Program Reference Point and Coordinate Values For a CNC lathe, coordinate axes X and Z are set on the machine and their intersecting point is called a “program reference point”. The X axis assumes a spindle center line to be a position of “XO”, and the Z axis assumes a workpiece finish end face on the tail stockTo machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. Programming with this type of coordinates implies the use of a "part zero" as a coordinate origin.This file is the Adobe Acrobat version of Denford G and M Programming for CNC Lathes. File Optimisation: On-screen display and printing. Graphics: resampled to 600 dpi.

haas lathe programming workbook PDF

This programming workbook provides basic principles necessary to program the Haas lathe. It is not intended as an in-depth study of all ranges of the machine use. Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.

metal shelf end brackets

This course describes the basic knowledge of CNC Lathe machining program and how to use the common instructions to the CNC control. The goal of this course is to help you to be able to prepare the basic machining program with referring the .Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment.

This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.Welcome to Productivity, Inc., your local Haas Factory Outlet (H.F.O.) for the Haas Lathe Programming Class. This class is intended to give a basic understanding of the set-up and operation of a Haas Turning Center.The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming examples are used to explain the commands and statements, which are also defined according to DIN 66025. 2. Work preparation2-1-1 Program Reference Point and Coordinate Values For a CNC lathe, coordinate axes X and Z are set on the machine and their intersecting point is called a “program reference point”. The X axis assumes a spindle center line to be a position of “XO”, and the Z axis assumes a workpiece finish end face on the tail stock

To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. Programming with this type of coordinates implies the use of a "part zero" as a coordinate origin.

cnc turning program examples PDF

cnc turning machine programming PDF

Electrical boxes, also known as junction boxes, are an essential component of any electrical system. They serve as a protective enclosure for electrical connections and devices, helping to prevent electrical fires and other .

cnc lathe machine programming pdf|cnc programming manual PDF