definition of cnc milling machine CNC milling is used to generate a flat surface using a milling machine. It requires a multi-point cutting tool or a milling-cutter. Unlike turning, the milling process relies on intermittent cutting and multiple machine steps.

A RDB Ferramentaria foi fundada em 2003, na cidade de Campinas, um dos mais importantes centros industriais e tecnológicos do Brasil. A empresa nasceu do desejo de aplicar a técnica e a tecnologia na usinagem de peças metálicas e não metálicas.

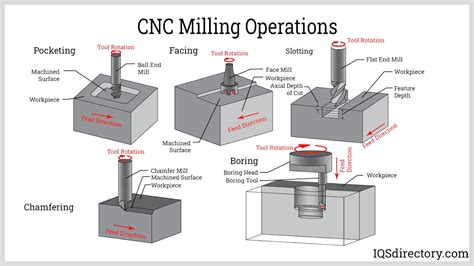

0 · types of cnc milling operations

1 · milling pros and cons

2 · milling process step by

3 · cnc milling machine uses

4 · cnc milling machine process

5 · cnc milling machine description

6 · cnc horizontal milling for dummies

7 · basics of the cnc mill

Get the best deals for Used Sheet Metal Roller at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

types of cnc milling operations

A CNC (Computer Numerical Control) milling machine or CNC mill is the computerized controlled machine features drilling and cutting tools for . A CNC milling machine is a sophisticated piece of equipment that automates the process of cutting and shaping materials, such as metal, plastic, or wood. Standing for Computer Numerical Control, CNC milling leverages .

CNC milling is the same milling machining process that we know and love, with the addition of computer control. Milling is the cutting of a material like metal, plastic, or wood, using a rotating tool. Every aspect, like cutter .

precision sheet metal products

CNC milling is a computer-controlled process and a specific type of CNC machining that involves cutting a block of material mounted on a machine bed with different rotating multi-point cutters to achieve the desired shape and . CNC milling is a machining process that uses computer numerical control to guide the movements of a cutting tool. This process can create highly precise parts with complex geometry. A three-dimensional model is first .CNC milling is used to generate a flat surface using a milling machine. It requires a multi-point cutting tool or a milling-cutter. Unlike turning, the milling process relies on intermittent cutting and multiple machine steps.CNC stands for Computer Numerical Control and refers to the automated control of machining tools, such as drills, lathes, mills, grinders, routers, and 3D printers, using a computer. The CNC machining process involves inputting coded .

CNC milling is a subtractive manufacturing process that combines traditional milling with computer numerical control (CNC) technology. It involves using a rotating cutting tool to remove material from a solid block of metal, plastic, wood, or other materials to create precise parts and products. A CNC (Computer Numerical Control) milling machine or CNC mill is the computerized controlled machine features drilling and cutting tools for completing the milling process.

A CNC milling machine is a sophisticated piece of equipment that automates the process of cutting and shaping materials, such as metal, plastic, or wood. Standing for Computer Numerical Control, CNC milling leverages computerized systems to control the movement and operation of the cutting tools with extreme precision. CNC milling is the same milling machining process that we know and love, with the addition of computer control. Milling is the cutting of a material like metal, plastic, or wood, using a rotating tool. Every aspect, like cutter toolpath, feed .

CNC milling is a computer-controlled process and a specific type of CNC machining that involves cutting a block of material mounted on a machine bed with different rotating multi-point cutters to achieve the desired shape and feature. CNC milling is a machining process that uses computer numerical control to guide the movements of a cutting tool. This process can create highly precise parts with complex geometry. A three-dimensional model is first created in computer-aided design (CAD) software to create complex parts.CNC milling is used to generate a flat surface using a milling machine. It requires a multi-point cutting tool or a milling-cutter. Unlike turning, the milling process relies on intermittent cutting and multiple machine steps.CNC stands for Computer Numerical Control and refers to the automated control of machining tools, such as drills, lathes, mills, grinders, routers, and 3D printers, using a computer. The CNC machining process involves inputting coded instructions into a computer, which translates the code into precise movements for the cutting tools.

CNC milling is a subset of CNC machining services, a broadly defined manufacturing process that includes CNC turning, CNC routing, and CNC drilling. CNC machining describes technologies that utilise computer-controlled tools to carve out portions of a block of material to create a part.CNC milling is a manufacturing process that uses computer-controlled machines to remove material from a workpiece. The process involves a cutting tool that rotates at high speeds and removes material from the workpiece to create a desired shape or design.

CNC milling is a subtractive manufacturing process that combines traditional milling with computer numerical control (CNC) technology. It involves using a rotating cutting tool to remove material from a solid block of metal, plastic, wood, or other materials to create precise parts and products.

A CNC (Computer Numerical Control) milling machine or CNC mill is the computerized controlled machine features drilling and cutting tools for completing the milling process.

A CNC milling machine is a sophisticated piece of equipment that automates the process of cutting and shaping materials, such as metal, plastic, or wood. Standing for Computer Numerical Control, CNC milling leverages computerized systems to control the movement and operation of the cutting tools with extreme precision. CNC milling is the same milling machining process that we know and love, with the addition of computer control. Milling is the cutting of a material like metal, plastic, or wood, using a rotating tool. Every aspect, like cutter toolpath, feed . CNC milling is a computer-controlled process and a specific type of CNC machining that involves cutting a block of material mounted on a machine bed with different rotating multi-point cutters to achieve the desired shape and feature. CNC milling is a machining process that uses computer numerical control to guide the movements of a cutting tool. This process can create highly precise parts with complex geometry. A three-dimensional model is first created in computer-aided design (CAD) software to create complex parts.

CNC milling is used to generate a flat surface using a milling machine. It requires a multi-point cutting tool or a milling-cutter. Unlike turning, the milling process relies on intermittent cutting and multiple machine steps.CNC stands for Computer Numerical Control and refers to the automated control of machining tools, such as drills, lathes, mills, grinders, routers, and 3D printers, using a computer. The CNC machining process involves inputting coded instructions into a computer, which translates the code into precise movements for the cutting tools.CNC milling is a subset of CNC machining services, a broadly defined manufacturing process that includes CNC turning, CNC routing, and CNC drilling. CNC machining describes technologies that utilise computer-controlled tools to carve out portions of a block of material to create a part.

prep-n-cook stainless steel 21.5 qt. canner 2 piece box

$162.26

definition of cnc milling machine|types of cnc milling operations