cnc machine axis direction Typically, a CNC lathe can have anywhere between two to seven axes. Each axis represents a direction in which the machine can move the cutting tool or the workpiece. The most common axes found in CNC lathes are the X, .

$100K+

0 · what is 5 axis machining

1 · cnc mill axis diagram

2 · cnc machine axis identification

3 · cnc axis explained

4 · 4 axis cnc milling machine

5 · 4 axis cnc mill

6 · 3 axis cnc milling machine

7 · 12 axis cnc machine

Search for used cnc parts. Find Okuma, Mori Seiki, Haas, Fuji, Citizen, and Hwacheon for sale on Machinio.

Place your hand in front of your CNC machine, aligned with the machine’s spindle, and you’ll see the axes line up perfectly. The thumb is the X-axis. The index finger is the Y-axis.The X-axis is arguably the most crucial component of any CNC machine. It represents the horizontal movement of the cutting tool along the workpiece, defining the machine's primary .CNC Milling Machine Ways provide a low friction precision sliding surface. Their job is to guide the motion so it is properly aligned to the axis and keep things moving freely and precisely. So here is the CNC axes directions convention: The spindle is ALWAYS the Z axis. The right hand rule is used to determine the linear axes and their direction. The middle finger .

Nearly all CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. This system allows a machine to move in a specific direction along a specific plane. Reduce the Cartesian system to its basics, .

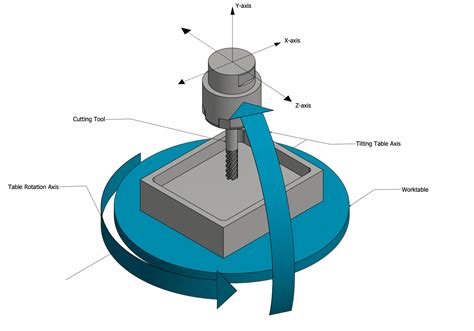

Typically, a CNC lathe can have anywhere between two to seven axes. Each axis represents a direction in which the machine can move the cutting tool or the workpiece. The most common axes found in CNC lathes are the X, .The most basic type is the 3-axis CNC milling machine, which allows for linear movement in the X, Y, and Z directions. On the other hand, the 4-axis CNC milling machine adds a rotational axis (A axis) to the X, Y, and Z movements, .CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).

CNC machines are typically categorized by the number of axes they can control. These axes represent the direction the machine’s tool or workpiece can move. Traditional CNC machines operate on three axes: X-axis: Horizontal .

Place your hand in front of your CNC machine, aligned with the machine’s spindle, and you’ll see the axes line up perfectly. The thumb is the X-axis. The index finger is the Y-axis. In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.The X-axis is arguably the most crucial component of any CNC machine. It represents the horizontal movement of the cutting tool along the workpiece, defining the machine's primary direction of motion.CNC Milling Machine Ways provide a low friction precision sliding surface. Their job is to guide the motion so it is properly aligned to the axis and keep things moving freely and precisely.

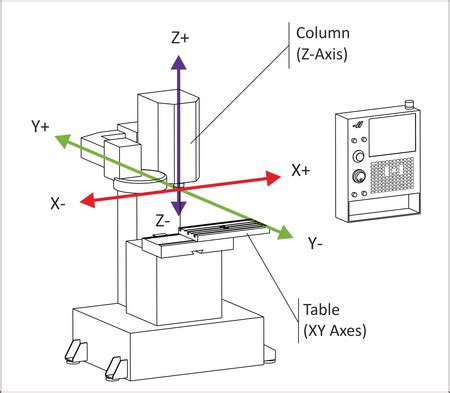

So here is the CNC axes directions convention: The spindle is ALWAYS the Z axis. The right hand rule is used to determine the linear axes and their direction. The middle finger is the Z axis, the thumb the X axis, and index finger the Y . Nearly all CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. This system allows a machine to move in a specific direction along a specific plane. Reduce the Cartesian system to its basics, and you have a familiar number line. Typically, a CNC lathe can have anywhere between two to seven axes. Each axis represents a direction in which the machine can move the cutting tool or the workpiece. The most common axes found in CNC lathes are the X, Z, and C axes.The most basic type is the 3-axis CNC milling machine, which allows for linear movement in the X, Y, and Z directions. On the other hand, the 4-axis CNC milling machine adds a rotational axis (A axis) to the X, Y, and Z movements, enabling machining on four sides of a .

CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).

what is 5 axis machining

cnc mill axis diagram

CNC machines are typically categorized by the number of axes they can control. These axes represent the direction the machine’s tool or workpiece can move. Traditional CNC machines operate on three axes: X-axis: Horizontal movement (left to right). Y-axis: Horizontal movement (front to back). Z-axis: Vertical movement (up and down).

Place your hand in front of your CNC machine, aligned with the machine’s spindle, and you’ll see the axes line up perfectly. The thumb is the X-axis. The index finger is the Y-axis.

In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

The X-axis is arguably the most crucial component of any CNC machine. It represents the horizontal movement of the cutting tool along the workpiece, defining the machine's primary direction of motion.

CNC Milling Machine Ways provide a low friction precision sliding surface. Their job is to guide the motion so it is properly aligned to the axis and keep things moving freely and precisely. So here is the CNC axes directions convention: The spindle is ALWAYS the Z axis. The right hand rule is used to determine the linear axes and their direction. The middle finger is the Z axis, the thumb the X axis, and index finger the Y . Nearly all CNC machine uses a Cartesian coordinate system based on an X, Y, and Z-axis. This system allows a machine to move in a specific direction along a specific plane. Reduce the Cartesian system to its basics, and you have a familiar number line. Typically, a CNC lathe can have anywhere between two to seven axes. Each axis represents a direction in which the machine can move the cutting tool or the workpiece. The most common axes found in CNC lathes are the X, Z, and C axes.

The most basic type is the 3-axis CNC milling machine, which allows for linear movement in the X, Y, and Z directions. On the other hand, the 4-axis CNC milling machine adds a rotational axis (A axis) to the X, Y, and Z movements, enabling machining on four sides of a .CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).

cnc machine axis identification

cnc axis explained

$3,995.00

cnc machine axis direction|12 axis cnc machine