building your own cnc machine worth it There’s no such thing as a free lunch in CNC, that being said there are some pretty good options. I’m sure you have come across MPCNC. It’s cheap and probably fits your criteria best. They . 2014 NEC allows weep holes in the box as long as the hole is ¼ in. or smaller. There is no limit on the number of holes or location where they are drilled but the holes must be “approved”. According to Article 100, “approved” means acceptable to .

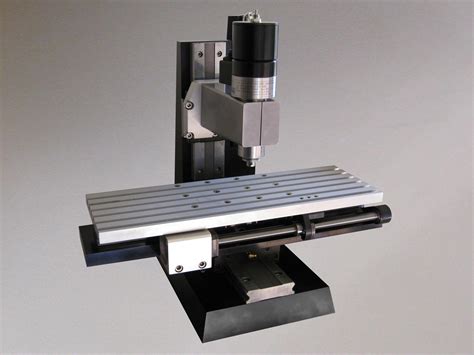

0 · make your own cnc mill

1 · homemade cnc router machine

2 · homemade cnc milling machine

3 · homemade cnc machine plans

4 · diy cnc machine for woodworking

5 · build your own cnc table

6 · build your own cnc mill

7 · build it yourself cnc router

For outlet boxes or outlet box systems designed to support ceiling-suspended (paddle) fans that weigh more than 16 kg (35 lb), the required marking shall include the maximum weight to be supported. If it's not labeled, the box is still required to support at least 50 lbs.

So biased as I may be in favor of diy, I'd say yes building your own cnc machine will teach you a lot, be patient stablish some reasonable expectations and check some existing open software /hardware projects such as FluidNC, GRBL, PrintNC, CindyMill.You’d definitely spend less on materials to build one than buying one. But consider the cost of your time in designing, building, adjusting, and tuning. From a business perspective, you’re .

There’s no such thing as a free lunch in CNC, that being said there are some pretty good options. I’m sure you have come across MPCNC. It’s cheap and probably fits your criteria best. They . The figure I heard from someone who ran a large engineering concern was that you needed a contract worth a minimum of seven times the cost of the CNC machine. Seven .While purchasing a commercially available CNC machine can be quite expensive, building your own DIY CNC machine is a cost-effective alternative that allows you to customize the design . But it remains true—building a CNC machine gives you the ability to manufacture your own amazing products. Whether you want to launch your own business, replace hard-to-find parts, or simply create custom products .

make your own cnc mill

Building a CNC machine requires careful planning and design. In this section, we will discuss the essential components you'll need, such as stepper motors, controller boards, power supplies, .

china sheet metal stamping part supplier

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY . So biased as I may be in favor of diy, I'd say yes building your own cnc machine will teach you a lot, be patient stablish some reasonable expectations and check some existing open software /hardware projects such as FluidNC, GRBL, PrintNC, CindyMill.

You’d definitely spend less on materials to build one than buying one. But consider the cost of your time in designing, building, adjusting, and tuning. From a business perspective, you’re probably better off buying. But if you also want to learn, building may be worth it. There’s no such thing as a free lunch in CNC, that being said there are some pretty good options. I’m sure you have come across MPCNC. It’s cheap and probably fits your criteria best. They are good machines and teach you a lot about building. Personally, I . The figure I heard from someone who ran a large engineering concern was that you needed a contract worth a minimum of seven times the cost of the CNC machine. Seven time was the absolute minimum if you were good at controlling the cost of consumable items, like getting cutters resharpened.

While purchasing a commercially available CNC machine can be quite expensive, building your own DIY CNC machine is a cost-effective alternative that allows you to customize the design and functionality to suit your specific needs. In this blog post, we will guide you through the step-by-step process of building your own CNC machine. But it remains true—building a CNC machine gives you the ability to manufacture your own amazing products. Whether you want to launch your own business, replace hard-to-find parts, or simply create custom products that aren’t available anywhere else, you .Building a CNC machine requires careful planning and design. In this section, we will discuss the essential components you'll need, such as stepper motors, controller boards, power supplies, and more. Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine. What is a CNC Machine?

Computer Numerical Control machines have revolutionized the manufacturing and hobbyist world. They offer precision, consistency, and automation to tasks that were previously manual and time-consuming. If you’re interested in crafting your very own CNC machine, you’ve come to the right place!Make Your Own DIY CNC: This instructable outlines the assembly process of my 2nd generation CNC machine which I designed to be simple to build and quiet enough to be apartment friendly. I have included example projects that I have made in the first two weeks of using the . So biased as I may be in favor of diy, I'd say yes building your own cnc machine will teach you a lot, be patient stablish some reasonable expectations and check some existing open software /hardware projects such as FluidNC, GRBL, PrintNC, CindyMill.

You’d definitely spend less on materials to build one than buying one. But consider the cost of your time in designing, building, adjusting, and tuning. From a business perspective, you’re probably better off buying. But if you also want to learn, building may be worth it. There’s no such thing as a free lunch in CNC, that being said there are some pretty good options. I’m sure you have come across MPCNC. It’s cheap and probably fits your criteria best. They are good machines and teach you a lot about building. Personally, I .

The figure I heard from someone who ran a large engineering concern was that you needed a contract worth a minimum of seven times the cost of the CNC machine. Seven time was the absolute minimum if you were good at controlling the cost of consumable items, like getting cutters resharpened.While purchasing a commercially available CNC machine can be quite expensive, building your own DIY CNC machine is a cost-effective alternative that allows you to customize the design and functionality to suit your specific needs. In this blog post, we will guide you through the step-by-step process of building your own CNC machine. But it remains true—building a CNC machine gives you the ability to manufacture your own amazing products. Whether you want to launch your own business, replace hard-to-find parts, or simply create custom products that aren’t available anywhere else, you .Building a CNC machine requires careful planning and design. In this section, we will discuss the essential components you'll need, such as stepper motors, controller boards, power supplies, and more.

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine. What is a CNC Machine? Computer Numerical Control machines have revolutionized the manufacturing and hobbyist world. They offer precision, consistency, and automation to tasks that were previously manual and time-consuming. If you’re interested in crafting your very own CNC machine, you’ve come to the right place!

Aluminum Alloy Guardrail Bed; ABS Double Rocking Hospital Bed; ABS Three Rocking Hospital Bed; Pediatric Bed; Patient Room Furniture. Mattress; Extendable Dining Table; . WEGO-PVDF Suture; WEGO-Polypropylene Suture; WEGO-NYLON Suture; WEGO-SILK Suture; WEGO-PGLA Suture; Orthopedic Trauma Solutions. Instrument Set B; Cranial;

building your own cnc machine worth it|build your own cnc table