clamps for outside junction box ADJUSTABLE AND FLEXIBLE: Clamps have adjustable range 1.96-7.87in(50 . Welding thin sheet metal can be challenging because you need to obtain adequate fusion while preventing distortion and burnthrough. The key skill is to control the heat across the sheet metal to prevent defects. This guide .

0 · romex clamps that pass code

1 · romex clamp size chart

2 · plastic electrical box wire clamps

3 · outlet box wire clamp

4 · junction box plastic wire clamp

5 · electrical junction box with connectors

6 · cable clamp for junction box

7 · breaker box wire clamp

Auto Body Sheet Metal Welding With Different Welders. Are you planning to weld auto body sheet metal or any thin metal with a MIG welder or tig welder? You should keep in mind some critical things to avoid creating any unwanted situations, and we have decided to incorporate them right here.

LeMotech Pole Mounting Kits, Stainless Steel 400mm Brackets with Adjustable 50-200mm Clamp for Outdoor Junction Box, Waterproof Plastic Electrical Enclosure (15.75"x1.89" Bracket)

QILIPSU Pole Mounting Kits, 304 Stainless 175x48mm Brackets with Adjustable 50 .ADJUSTABLE AND FLEXIBLE: Clamps have adjustable range 1.96-7.87in(50 .

.99 QILIPSU Pole Mounting Kits, 304 Stainless 175x48mm Brackets with Adjustable 50-200mm Clamp for Outdoor Waterproof Junction Box, .QILIPSU Pole Mounting Kits, 304 Stainless 250x48mm Brackets with Adjustable 50-200mm Clamp for Outdoor Waterproof Junction Box, Plastic Electrical Enclosure Project Box (9.8"x1.9")8.88

romex clamps that pass code

.99.95.99.99

steel city boxing hamilton north

9.99 The problem is that you should use a connector in the box. A button connector won't work since the 1/2" KO in the box is threaded. A typical metal .

Exterior boxes should be attached with screws; the back of the box should have small holes for that purpose. If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on .

steel city cabinet saw price

romex clamp size chart

Run the clamp screws in until they bite into the wood. Remove the box. At the marks left by the clamp screws, drill 1/4 inch relief holes about 1 inch into the stud to make room for the ends of the screws; Reinstall the box. Method 2. . ADJUSTABLE AND FLEXIBLE: Clamps have adjustable range 1.96-7.87in(50-200mm), suitable for mounting to various poles within its diameter. WEIGHT CAPACITY: 66lbs . Solution: Use a cable clamp. “When using metal junction boxes, it is important to use a cable clamp to ensure the cable is securely fastened within the box and conductors will not get exposed outside of the box,” says Chris .

Sometimes called a retrofit box, this type of electrical box attaches to the drywall with wings or ears that clamp the box to the drywall. Standard rectangular boxes, or single .

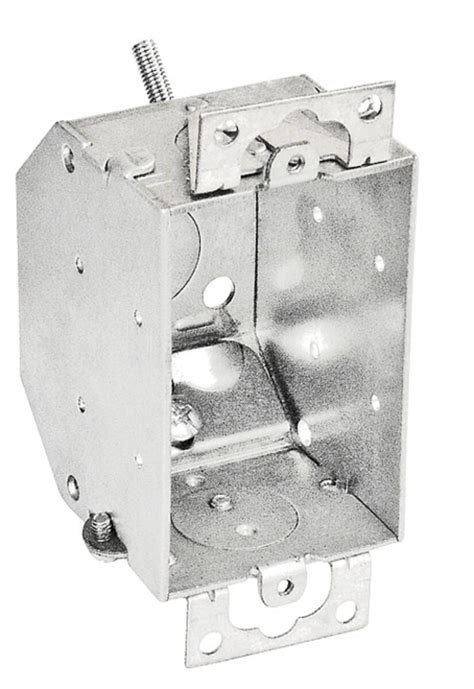

Some metal boxes have pre-attached clamps for gripping the electrical cable. Other boxes require you to purchase separate clamps, driving up the total cost of the box.LeMotech Pole Mounting Kits, Stainless Steel 400mm Brackets with Adjustable 50-200mm Clamp for Outdoor Junction Box, Waterproof Plastic Electrical Enclosure (15.75"x1.89" Bracket) QILIPSU Pole Mounting Kits, 304 Stainless 175x48mm Brackets with Adjustable 50-200mm Clamp for Outdoor Waterproof Junction Box, Plastic Electrical Enclosure Project Box (6.9"x1.9") - Amazon.com

QILIPSU Pole Mounting Kits, 304 Stainless 250x48mm Brackets with Adjustable 50-200mm Clamp for Outdoor Waterproof Junction Box, Plastic Electrical Enclosure Project Box (9.8"x1.9")

The problem is that you should use a connector in the box. A button connector won't work since the 1/2" KO in the box is threaded. A typical metal 2-screw romex squeeze connector works, but it requires a 1-1/2" hole in the brick to accommodate it's size. Exterior boxes should be attached with screws; the back of the box should have small holes for that purpose. If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on either side of the box). You’ll also need to install cable clamps in the metal box. These thread into the box from the outside.

Run the clamp screws in until they bite into the wood. Remove the box. At the marks left by the clamp screws, drill 1/4 inch relief holes about 1 inch into the stud to make room for the ends of the screws; Reinstall the box. Method 2. Remove the existing clamps After looking at the comments, the real problem isn't the knockout, it's a clamp that will work with access only to the inside of the box. Luckily, this is a solved problem. There are plastic push-in NM connectors made to install inside the box, such as the Raco Insider: ADJUSTABLE AND FLEXIBLE: Clamps have adjustable range 1.96-7.87in(50-200mm), suitable for mounting to various poles within its diameter. WEIGHT CAPACITY: 66lbs (30kg) ; Applicable to LeMotech stainless steel latch junction box or any other electrical enclosure with mounting holes. You'll need a 3/4" snap-in NM clamp that can be installed from the inside of the box. You do need a NM clamp (vs a mere bushing) here, first off; a simple bushing does not provide the clamping of the cable jacket required by NEC 312.5(C) for .

plastic electrical box wire clamps

Solution: Use a cable clamp. “When using metal junction boxes, it is important to use a cable clamp to ensure the cable is securely fastened within the box and conductors will not get exposed outside of the box,” says Chris Lozano, master .LeMotech Pole Mounting Kits, Stainless Steel 400mm Brackets with Adjustable 50-200mm Clamp for Outdoor Junction Box, Waterproof Plastic Electrical Enclosure (15.75"x1.89" Bracket)

QILIPSU Pole Mounting Kits, 304 Stainless 175x48mm Brackets with Adjustable 50-200mm Clamp for Outdoor Waterproof Junction Box, Plastic Electrical Enclosure Project Box (6.9"x1.9") - Amazon.comQILIPSU Pole Mounting Kits, 304 Stainless 250x48mm Brackets with Adjustable 50-200mm Clamp for Outdoor Waterproof Junction Box, Plastic Electrical Enclosure Project Box (9.8"x1.9") The problem is that you should use a connector in the box. A button connector won't work since the 1/2" KO in the box is threaded. A typical metal 2-screw romex squeeze connector works, but it requires a 1-1/2" hole in the brick to accommodate it's size.

Exterior boxes should be attached with screws; the back of the box should have small holes for that purpose. If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on either side of the box). You’ll also need to install cable clamps in the metal box. These thread into the box from the outside.

Run the clamp screws in until they bite into the wood. Remove the box. At the marks left by the clamp screws, drill 1/4 inch relief holes about 1 inch into the stud to make room for the ends of the screws; Reinstall the box. Method 2. Remove the existing clamps After looking at the comments, the real problem isn't the knockout, it's a clamp that will work with access only to the inside of the box. Luckily, this is a solved problem. There are plastic push-in NM connectors made to install inside the box, such as the Raco Insider:

ADJUSTABLE AND FLEXIBLE: Clamps have adjustable range 1.96-7.87in(50-200mm), suitable for mounting to various poles within its diameter. WEIGHT CAPACITY: 66lbs (30kg) ; Applicable to LeMotech stainless steel latch junction box or any other electrical enclosure with mounting holes. You'll need a 3/4" snap-in NM clamp that can be installed from the inside of the box. You do need a NM clamp (vs a mere bushing) here, first off; a simple bushing does not provide the clamping of the cable jacket required by NEC 312.5(C) for .

7 months ago I upgraded(?) to a Titanium Multi Process welder from Harbor Freight. It is currently setup with 0.025 wire, 75/25 gas, and 120V. I had the welder dialed in to where I liked it for 18 gauge sheet metal, but now I am having an absolutely terrible time with burn back.

clamps for outside junction box|breaker box wire clamp