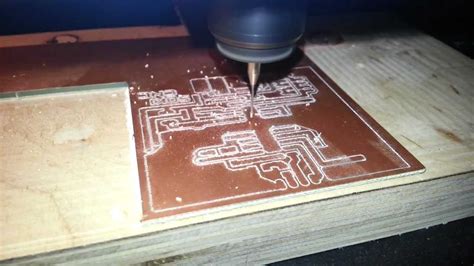

circuit cnc machine Learn how to use a CNC mill to create your own printed circuit boards (PCBs) for prototyping and testing circuit designs. Find out the steps, . These are the sheet metal thickness, material, size, and interior layout. For thickness, we use anywhere between 16 gauge and 3/16” depending on the strength requirements and any applicable UL or NEC requirements.

0 · printed circuit board milling machine

1 · pcb milling machine for hobbyist

2 · making pcb with cnc router

3 · cnc router pcb milling

4 · cnc router for pcb

5 · cnc machine for pcb making

6 · cnc machine for pcb fabrication

7 · circuit board cnc machine

An electrical junction box can be made of either metal or plastic. They usually measure 2½ inches deep or 3½ inches deep. The larger of the two is able to hold up to five different wires, while the smaller only holds three wires.

Prometheus is a PCB (printed circuit board) milling machine. It works by milling (or carving/engraving) your circuit design into a standard copper-clad board.

metal house kit

Category: All Categories Electronics Electronics October 4, 2016 PWM and .Rocco TuccioFounder I have a passion for learning and creating things, an .ProCAM ProCAM is CAM (computer aided manufacturing) software for .

printed circuit board milling machine

Learn how to use a CNC mill to create your own printed circuit boards (PCBs) for prototyping and testing circuit designs. Find out the steps, .Make Your Own PCBs on an Inexpensive Desktop CNC Mill: Traditionally, there are two ways of hobbyists making custom PCBs: 1. Using toner transfer and .

If you ever wanted to make PCBs of your own, and if you have access to a milling machine, then this tutorial will cover all the basics. This is a .Computer numerical control (CNC) machining is an essential part of taking your printed circuit board (PCB) design from prototype to production. CNC milling accurately fabricates complex 2.5D and 3D features on custom PCBs that .One of the key tools in the PCB making process is a CNC (Computer Numerical Control) machine. In this comprehensive guide, we will take a deep dive into the world of PCB making . While single-sided PCBs are simple and ideal to use when possible, many circuits require two sides. Double-sided boards offer a wide variety of possibilities for circuit board designers because they have more .

pcb milling machine for hobbyist

making pcb with cnc router

The low-cost computer-numerical-control (CNC) machine is just one of many on the market capable of milling a circuit board from a raw slab of copper-clad non-conductive substrate.

For this tutorial we are going to take a design that we made from EAGLE, use PCB-GCode and Autoleveler software to load it into our ZEN Toolworks Mach 3 CNC machine. What we can do is then create circuit boards using our own .

Prometheus is a PCB (printed circuit board) milling machine. It works by milling (or carving/engraving) your circuit design into a standard copper-clad board.

Each one is a smaller CNC mill designed to deliver maximum power within a compact package, all at an affordable price. Regardless of your project or material, whether it’s metal or plastic, our CNC machines empower you to create whatever you envision. To fully harness the precision and control of these benchtop mills, all you need is a .Make Your Own PCBs on an Inexpensive Desktop CNC Mill: Traditionally, there are two ways of hobbyists making custom PCBs: 1. Using toner transfer and chemical etchant -- can be tricky to get the right materials, and the chemicals are nasty and messy 2. Paying a service like BatchPCB or OshPark -- fairly. If you ever wanted to make PCBs of your own, and if you have access to a milling machine, then this tutorial will cover all the basics. This is a really simple and short tutorial that will help you start making PCBs using the Roland PCB milling machine (Roland Modela MDX-20).Milling Printed Circuit Boards (PCBs) on a Cheap CNC Machine: This guide presents an entire end-to-end process of milling PCBs with a "cheap" 3018 CNC machine (although other CNC machine types can also be used).

Computer numerical control (CNC) machining is an essential part of taking your printed circuit board (PCB) design from prototype to production. CNC milling accurately fabricates complex 2.5D and 3D features on custom PCBs that cannot be achieved with traditional manufacturing means.One of the key tools in the PCB making process is a CNC (Computer Numerical Control) machine. In this comprehensive guide, we will take a deep dive into the world of PCB making CNC machines, their importance, working principle, and how to use them effectively for the production of high-quality PCBs. Table of Contents: 1.

While single-sided PCBs are simple and ideal to use when possible, many circuits require two sides. Double-sided boards offer a wide variety of possibilities for circuit board designers because they have more surface area and flexibility when routing traces. The low-cost computer-numerical-control (CNC) machine is just one of many on the market capable of milling a circuit board from a raw slab of copper-clad non-conductive substrate.

For this tutorial we are going to take a design that we made from EAGLE, use PCB-GCode and Autoleveler software to load it into our ZEN Toolworks Mach 3 CNC machine. What we can do is then create circuit boards using our own designs right before our very eyes. Materials Needed: ZEN Toolworks CNC machine with Mach 3 driver package.Prometheus is a PCB (printed circuit board) milling machine. It works by milling (or carving/engraving) your circuit design into a standard copper-clad board. Each one is a smaller CNC mill designed to deliver maximum power within a compact package, all at an affordable price. Regardless of your project or material, whether it’s metal or plastic, our CNC machines empower you to create whatever you envision. To fully harness the precision and control of these benchtop mills, all you need is a .

Make Your Own PCBs on an Inexpensive Desktop CNC Mill: Traditionally, there are two ways of hobbyists making custom PCBs: 1. Using toner transfer and chemical etchant -- can be tricky to get the right materials, and the chemicals are nasty and messy 2. Paying a service like BatchPCB or OshPark -- fairly.

cnc router pcb milling

If you ever wanted to make PCBs of your own, and if you have access to a milling machine, then this tutorial will cover all the basics. This is a really simple and short tutorial that will help you start making PCBs using the Roland PCB milling machine (Roland Modela MDX-20).Milling Printed Circuit Boards (PCBs) on a Cheap CNC Machine: This guide presents an entire end-to-end process of milling PCBs with a "cheap" 3018 CNC machine (although other CNC machine types can also be used).Computer numerical control (CNC) machining is an essential part of taking your printed circuit board (PCB) design from prototype to production. CNC milling accurately fabricates complex 2.5D and 3D features on custom PCBs that cannot be achieved with traditional manufacturing means.One of the key tools in the PCB making process is a CNC (Computer Numerical Control) machine. In this comprehensive guide, we will take a deep dive into the world of PCB making CNC machines, their importance, working principle, and how to use them effectively for the production of high-quality PCBs. Table of Contents: 1.

While single-sided PCBs are simple and ideal to use when possible, many circuits require two sides. Double-sided boards offer a wide variety of possibilities for circuit board designers because they have more surface area and flexibility when routing traces.

The low-cost computer-numerical-control (CNC) machine is just one of many on the market capable of milling a circuit board from a raw slab of copper-clad non-conductive substrate.

cnc router for pcb

Best for: Outdoor electrical needs; Weatherproof outdoor boxes are sealed enclosures designed for mounting to the surface of exterior walls, roof overhangs, decks, and other structures. They are used for installing outdoor receptacles (outlets) and light fixtures.

circuit cnc machine|cnc machine for pcb fabrication