bump forming sheet metal Bump forming also known as bump bending, step bending, or repetitive v-bending, is a popular sheet metal fabrication art of bending sheet metal materials into desirable cylindrical or conical shapes for different industry applications using a press brake. Junction boxes keep wiring clean and secure, ensuring longer-lasting electrical connections. By safeguarding wiring from physical damage, junction boxes help prolong the lifespan and reliability of electrical systems, which is particularly important in environments where wear and tear are prevalent. Facilitating Circuit Modifications

0 · step bending sheet metal

1 · step bending

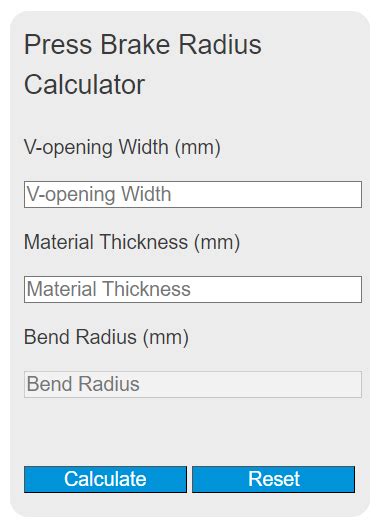

2 · press brake radius calculator

3 · large radius sheet metal bending

4 · how to calculate bumps

5 · bump rolling vs roll forming

6 · bump bending calculator

7 · bump bending

To provide a quality outsourcing solution to Mechanical Contractors. Let us save you time, money, and headaches by providing you with a virtual 3-D model of the engineers concept and the construction reality of building a mechanical system, together. Fully COORDINATED, ready for FABRICATION and INSTALL!

Bump forming also known as bump bending, step bending, or repetitive v-bending, is a popular sheet metal fabrication art of bending sheet metal materials into desirable cylindrical or conical shapes for different . Bump-forming is a metal bending technique that uses a series of bends to create a cylindrical bend in your metal sheet. It's often more efficient .

Each individual “bump” is in essence an extremely wide radius bend, just a few degrees complementary, and measuring that creates challenges. As Linderot explained, .

fm sheet metal eugene oregon

The multi-step forming process is a sophisticated technique for achieving large-radius bends in sheet metal using smaller radius punches. This method’s fundamental principle involves segmenting the desired arc into multiple polyline sections, as illustrated in Figure 1. Bump forming also known as bump bending, step bending, or repetitive v-bending, is a popular sheet metal fabrication art of bending sheet metal materials into desirable cylindrical or conical shapes for different industry applications using a press brake. Bump-forming is a metal bending technique that uses a series of bends to create a cylindrical bend in your metal sheet. It's often more efficient and cost-effective for low-volume orders or prototypes, while hard tooling is necessary . Each individual “bump” is in essence an extremely wide radius bend, just a few degrees complementary, and measuring that creates challenges. As Linderot explained, measurement systems in adaptive forming start to work when a bend angle reaches between 9 and 25 degrees complementary, depending on the specific technology used.

Step bending is a procedure in which multiple hits (bends) are made along the entire length of the inside radius to produce the bend. The number of hits used in this process will determine the tooling selection, smoothness of the final surface, and the .

step bending sheet metal

You can obtain very wide radiused bends on a press brake without using round punches, with a technique called multiple-step bending, also called bump bending. Actual section is not a true arc of a circle but a segmented line, formed by several straight lines. This month we delve into the intricacies of bump bending and go back to basics with air forming, reviewing the relationship between the die opening, the inside bend radius, and the material thickness.

K-zell Metals offers metal bump form bending services to put a radius in sheets or plates utilizing a CNC press brake. Contact us for all your bump form bending needs!Step Bending, or Bump Bending is a method for forming a Large Bend Radius in a sheet metal part, without the need for special tooling, by creating a series of highly open bends in close proximity. This method will have advantages over using a roller because the length of the rolled section can be controlled more precisely with high repeatability.

In his new book, Bending Basics, Steve Benson explains many key concepts for getting the most out of your bending equipment. The chapter on bump radius bending explains how to calculate the best approach for your large-radius bend without employing special tooling.

The multi-step forming process is a sophisticated technique for achieving large-radius bends in sheet metal using smaller radius punches. This method’s fundamental principle involves segmenting the desired arc into multiple polyline sections, as illustrated in Figure 1. Bump forming also known as bump bending, step bending, or repetitive v-bending, is a popular sheet metal fabrication art of bending sheet metal materials into desirable cylindrical or conical shapes for different industry applications using a press brake.

Bump-forming is a metal bending technique that uses a series of bends to create a cylindrical bend in your metal sheet. It's often more efficient and cost-effective for low-volume orders or prototypes, while hard tooling is necessary .

Each individual “bump” is in essence an extremely wide radius bend, just a few degrees complementary, and measuring that creates challenges. As Linderot explained, measurement systems in adaptive forming start to work when a bend angle reaches between 9 and 25 degrees complementary, depending on the specific technology used. Step bending is a procedure in which multiple hits (bends) are made along the entire length of the inside radius to produce the bend. The number of hits used in this process will determine the tooling selection, smoothness of the final surface, and the .You can obtain very wide radiused bends on a press brake without using round punches, with a technique called multiple-step bending, also called bump bending. Actual section is not a true arc of a circle but a segmented line, formed by several straight lines.

This month we delve into the intricacies of bump bending and go back to basics with air forming, reviewing the relationship between the die opening, the inside bend radius, and the material thickness.K-zell Metals offers metal bump form bending services to put a radius in sheets or plates utilizing a CNC press brake. Contact us for all your bump form bending needs!

food processing industry sheet metal fabrication

Step Bending, or Bump Bending is a method for forming a Large Bend Radius in a sheet metal part, without the need for special tooling, by creating a series of highly open bends in close proximity. This method will have advantages over using a roller because the length of the rolled section can be controlled more precisely with high repeatability.

step bending

press brake radius calculator

food grade metal fabrication

large radius sheet metal bending

Have occasionally smell scent of what smells like metal burning upstairs. Last night circuit in bedroom lights went out. - Answered by a verified Electrician

bump forming sheet metal|bump bending