what is cnc laser machine A CNC laser cutter is a piece of computer numerical control (CNC) equipment that uses a focused, high-powered laser beam to mark, cut, or engrave a material to form custom shapes. . Metallic fabric is a type of fabric that has a metallic appearance. This fabric is typically made from polyester film and has high elasticity and durability1. Metallic fibers are a type of fiber used in composite materials and are highly .Metallic fabrics are a surefire way to make a statement, whether in bold evening wear or as an accent in an everyday look. But how do you find the perfect metallic fabric, and what are the different types? Learn all this and more in our Zelouf .

0 · laser cnc machines for woodworking

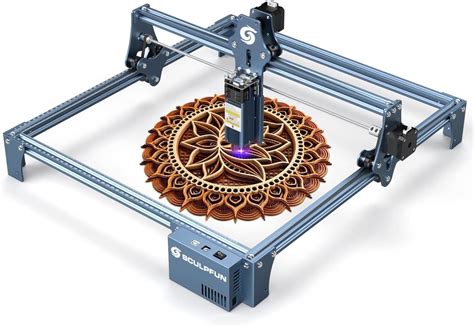

1 · laser cnc machine hobby

2 · laser cnc machine for wood

3 · highest rated industrial laser engraver

4 · best laser for cnc machine

5 · best laser engravers for hobbyists

6 · best laser engraver for home use

7 · best laser cutting machine for hobbyist

Junction boxes are must-have units at home as they protect against electrical issues. Here are a few of the most common junction boxes and where to use them.

Both laser cutters and CNC machines are subtractive manufacturing processes that use computer numerical control (CNC). This means you use design software to design the part, and control software to generate . A CNC laser is a cutting-edge technology that uses a high-powered laser beam to cut and engrave various materials with precision. By focusing the laser beam onto the material, CNC lasers can create rapid . Computer Numeric Control, better known as CNC, uses dedicated tooling to produce various shapes and sizes of parts. When a designer creates a drawing based on a customer’s specifications, the process begins.A CNC laser cutter is a piece of computer numerical control (CNC) equipment that uses a focused, high-powered laser beam to mark, cut, or engrave a material to form custom shapes. .

Laser cutting machines are a capable and versatile class of numerically controlled machine tools. They are used in virtually all industries for high throughput, precision cutting, engraving, and marking—from home use . CNC and laser cutters are versatile machines that can be used for a variety of cutting and engraving tasks. While both laser cutters and CNCs are popularly used in subtractive manufacturing, there are significant differences . Having tested many of the best laser cutters and engravers, we created our recommendations for the best laser cutting machines in each price range, for each use, and more. I also link to some of my detailed hands-on .

We can define a CNC laser cutter as it is a process of laser cutting service using computerized technology. Just like the other CNC cutting machine. CNC laser engraver also cuts metals, woods, acrylic, paper, and so on. But the only .In our increasingly digital world, CNC laser cutting has emerged as a crucial technology in various sectors, including manufacturing, engineering, and design. This guide provides an in-depth understanding of CNC laser cutting, its . A CNC (Computer Numerical Control) CO2 laser cutting machine is a machine that cuts metal using a high-powered laser beam. The laser is produced by a carbon dioxide gas mixture and directed by a computer control system to create the desired cut.

laser cnc machines for woodworking

CNC Laser Machines cut sheet metal Applications of CNC Laser Machines. CNC laser machines are utilized in a wide range of applications, including: Cutting and Engraving: From intricate designs to robust industrial applications, CNC lasers are capable of achieving precise cuts and detailed engravings on various materials. CNC laser machines use a combination of mirrors, lenses, and other components to direct and focus the laser beam onto the material surface. The computer program controls the speed, power, and direction of the laser beam, allowing for precise and accurate cuts and engravings. CNC laser technology is widely used in manufacturing, prototyping, and . Budget: Evaluate your budget as laser engravers and CNC machines vary in cost. Laser engravers, especially smaller desktop versions, are generally more affordable compared to CNC machines, which can range from moderate to high cost depending on the size and capabilities. Space Availability: Consider the available space in your workshop or .

CNC machines usually use G codes to describe the machining information of the machine tool, such as the tool path, the selection of coordinates, and the opening of the coolant. It is the main function of the G-code interpreter to interpret G-codes into data blocks that can be recognized by the CNC system.CNC laser cutting machine is almost similar to the router and plasma cutting machine. There are various kinds of laser machines. They are: Laser diodes: Laser diodes are typically 5 watts in power. C0₂ Gas lasers: This is the most common type in laser engraver machines. The layers contain CO₂ gas.

jack in the box grand junction

Types of CNC Machines. CNC machining is a manufacturing process that uses computerized controls to operate and manipulate machine tools, shaping a variety of materials into custom parts and designs. There are several types of CNC machines, . What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials.; Types of CNC machines: There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.Each machine has its own advantages and . CNC laser cutting machines are revolutionizing the manufacturing industry with their precision and efficiency. These machines use a high-powered laser beam to cut through various materials, such as metal, wood, and plastic, with incredible accuracy. With their computer-controlled systems, CNC laser cutting machines can create intricate designs and shapes that .The Trumpf TRULASER5000 is a leading CNC laser cutting machine renowned for its precision and efficiency. Equipped with a robust laser cutting system, it is designed to handle a variety of materials, including metal and alloys. Ideal for industries such as automotive, aerospace, and heavy machinery, the TRULASER5000 excels in producing complex .

A CNC laser machine is a computer-controlled machine that utilizes laser technology for cutting, engraving, or marking various materials. It uses a high-powered laser beam to perform precise and intricate operations on materials such as wood, metal, acrylic, and more.CNC laser cutting machine has a laser cutting tool. On the other CNC machine have a different cutting tool like plasma cutter or the router or others. But, all of them have a computer to operate the machining system. It is known as CNC or Computer Numeric Control. Let’s focus on the CNC laser engraver machine. In today’s manufacturing landscape, CNC laser cutting machines play a pivotal role in creating precise and intricate designs. However, mastering these powerful tools requires comprehensive training. Whether you’re a novice or looking to enhance your skills, CNC laser cutting machine training is essential.

The Trumpf TruLaser 1030 is a cutting-edge CNC laser cutting machine, widely used in industries such as automotive, aerospace, and manufacturing. It processes materials like steel, aluminum, and copper with accuracy, thanks to its advanced laser technology. Its capability to handle various thicknesses and complex geometries makes it a versatile .

The cnc laser engraver is the main tool used in the process. It contains a computer-controlled laser module/head, the source of the focused light beam. The laser engraving process is fairly straightforward. First, the material . The two machines we’ve covered so far have both been desktop size for small home workshops, but MakerMade 2 in 1 isn’t. This is a much larger 4x8ft CNC laser router, so it’s ideal for working on much larger projects. The SnapMaker artisan is the perfect all-in-one machine that functions as a laser, printer, and CNC combo. It is not for the budget-conscious, as it will set you back ,999. However, it is . The Laser Cutter Machine will Continue the Epoch-Making Product Revolution. The laser source is the core component of the cutter, and also an important indicator that determines the type and cutting ability of a laser cutter. Needless to say, future changes in laser cutters will also occur in laser sources. . As a high-precision CNC laser .

The laser machine is fed with a laser cut file, which has all the necessary instructions and cutting paths for the laser head. Technically speaking, the laser cutter is a kind of CNC machine, as it is also programmed to cut through a guided path. That’s why, sometimes we refer to industrial laser cutting machines as CNC laser cutters. However .CNC Machine is PC controlled manufacturing machine responsible for producing a majority of the worlds goods. Rapid Results AI. Login / Signup. CNC Machines (1442) CNC Mill (798) . The type of cutting can vary from plasma cutting to laser cutting, milling, routing, and lathes. CNC machines can even pick up and move items on an assembly line.

Read our CNC grinding machine buyer’s guide. CNC Laser Cutters How does a CNC laser cutter work? CNC laser cutting is a non-contact, thermal-based machining operation that focuses a high-intensity laser beam on a metal workpiece, melting and cutting it .What is CNC machining? By: CapableMaching Preface: Introduction Deep understanding and CNC machining First, let me explain what CNC is. The full name of CNC is Computer Numerical Control. CNC machining stands for Computer Numerical Control machining. It’s a manufacturing process where pre-programmed computer software dictates the movement of machinery and .

Building a laser for the first time can be an intimidating process, so pick a fast machine to assemble, or buy a pre-assembled machine like the xTool S1. Entry-level laser cutters usually come as kits to build, and can take up to an hour to build.

Understanding your usage needs in a CNC laser cutting machine helps you pick the ideal machine for your short-term and long-term usage. By utilizing this comprehensive guide, you can better understand how a CNC laser cutting machine operates and the range of materials it can cut and obtain valuable insights on selecting the perfect one for your .

The Multicam Magnus CO2 Laser is a CNC system specializing in laser cutting. Utilizing CO2 technology, it efficiently performs precise cuts and engravings essential to industries such as signage, automotive, and textiles. . Suitable materials for processing include acrylic, wood, and leather. This machine harnesses laser capability to meet . How CNC laser cutting machines work. When lasers are directed towards the surface of a workpiece using an optical system, a high energy density laser beam is produced, which causes the material to heat, melt, and evaporate rapidly. This is how a CNC laser cutting machine operates. A CNC metal laser cutter operates by concentrating a high-powered laser beam onto a metal surface to melt, burn, or vaporize the material. The term “CNC” stands for “Computer Numerical Control,” which means that a computer is used to direct the motion and output of the laser beam based on a predefined set of commands and patterns.

laser cnc machine hobby

jack daniels metal box with 2 glasses

j501 junction box

Sheet metal shearing is a fundamental fabrication process that involves slicing through metal sheets to separate them into different sizes and shapes. This technique uses a .

what is cnc laser machine|best laser engravers for hobbyists