sheet metal cone rolling Rolling a Long Cone from Sheetmetal. Ron Covell. 207K subscribers. Subscribed. 4.4K. 134K views 1 year ago. See how to roll a long cone from 16-gauge (1.6mm) sheetmetal. .more. Covell. 31 Traveling Sheet Metal Jobs jobs available on Indeed.com. Apply to Welder, Ironworker, Mig and Tig Welder and more!

0 · weight of a cone calculator

1 · sheet metal cone rolling machine

2 · sheet metal cone rolling calculation

3 · sheet metal cone calculator

4 · cone weight calculator in mm

5 · cone weight calculator in kg

6 · cone layout calculator

7 · cone dimension calculator

Slotting is a sheet metal process where a slot is put in the metal to do its job. Also known as slitting, the machines used in the process are called slitting machines. The process involves cutting notches in the steel sheets and removing the excess metal with a chisel.

weight of a cone calculator

metal support brackets for microwave

sheet metal cone rolling machine

Arntzen has over 60 years of steel cone rolling experience, so you can count on us to manufacture your custom metal cone correctly and economically. Contact us today! Arntzen .Arntzen has years 64 years of steel cone rolling experience, count on us to .The curved steel cone calculator from Chicago Metal Rolled Products makes it easy to find the precise curved steel cone dimensions you need.

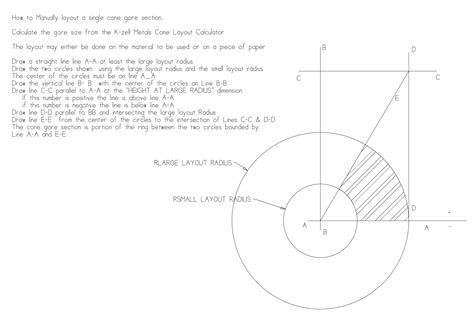

Rolling a Long Cone from Sheetmetal. Ron Covell. 207K subscribers. Subscribed. 4.4K. 134K views 1 year ago. See how to roll a long cone from 16-gauge (1.6mm) sheetmetal. .more. Covell. Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It .Halvorsen rolls, forms, welds and fabricates heavy steel and metal plate to manufacture custom cones, cylinders, segments, hoppers, elbows and transitions.

Metal rolling is a process that utilizes a number of techniques, including sheet metal rolling and cone rolling. With the ability to produce complex components, plate rolling is an invaluable fabrication process that demands precision and .Sheet Metal Cone Rolling,Model: W12-8×2000, bending thickness 8mm, pre-bending 6mm, width effective 2100mm, top roller 210mm, PLC control, short flat ends, different shapes, smaller diameter, top crane, side supports and cone .

metal studs electrical outlet boxes

Halvorsen rolls, forms, welds and fabricates heavy steel and metal plate to manufacture custom cones, cylinders, segments, hoppers, elbows and transitions. ASME PRESSURE VESSELS • HEAVY PLATE FABRICATION . Plate Rolling; Welding; Contact. Sales; Careers; Location and Directions; About Us. Quality Control; What People Say; Who We Serve .Cone Rolling. Linders Specialty Company’s plate rolling expertise is especially notable in the application of cone rolling. While many organizations are able to do standard plate rolling Linders Specialty Company has developed a truly unique niche in being the premier producer of rolled cones. We can produce your cone projects accurately and repetitively to within our tight . Learn from Avon Lake Sheet Metal experts about fabricating high-quality sheet metal cones for industrial and commercial applications. Skip to content. Call Us Today 440-933-3505. Search. . or by using a cone-rolling machine. Professional sheet metal fabrication companies have the expertise and specialized equipment necessary to form the cone .Steel plate rolling is a process that creates bends in different materials as we work with aluminum, steel, stainless and galvanized steel, perforated metal and other resources. APX York Sheet Metal specialists can create products like channels, enclosures, frames, cones, hoppers, ductwork, machine housings, molds, stacks, piping and bridges. We can also create rolled .

Cone Calculator is used to calculate Fabrication Layout Markings or Flat Pattern Layout Marking of Full Cone, Half Cone or Truncated Cone, Multi-Level concentric Cone, Eccentric Cone, Multi-Level Eccentric Cone, Tori Cone with Knuckle Radius at .On most of our machines, rolling a sheet metal cone shape can be formed by pre-cutting a flat metal blank with the correct inner and outer radius to form the cone (funnel) shape wanted. Normally the blank is fed on one side so that the inner radius can be slowed or stopped against a cone rolling attachment. When you roll sheet metal, the spacing of the third, opposing roller determines the radius of the curve. I have misadjusted the two ends of this roller on my sheet metal machine and produced a slight cone shape when it was not wanted. Couldn't this allow you to roll a cone with three straight rollers.

In this video I make a sheet-metal slip roll for shaping cones and cylinders. The tool I made is quite small, but yet very rigid due to the variable width de.

Campo Sheet Metal Works Inc. of Houston, TX offers plate rolling, custom plate rolling and steel plate rolling. Call 832-325-6300 for more information now. . 16′ ID Rolled Cone Segment Davi Machine rolling 3/4″ Stainless Steel Heavy Weight Cylinder Rolled Perforated Cylinder Rolled Cylinder Get in Touch. Name * Email * .

The Morgan Rushworth Conical Sheet Bending Rolls are capable of bending light plates, aluminium and stainless steel material into conical shapes. . Mechanical Sheet Metal Guillotines; Hydraulic Sheet Metal Guillotines; Steelworkers; . Rolling Capacity: mm: 3 4: Min. Bending Diameter: mm: 63 105: Top Roll Diameter: mm:

Plate rolling is a metal-forming process used to shape sheet metal plates into a variety of cylindrical shapes, including cylinders, cones, and ellipses. The process involves feeding a flat metal plate through a set of three or more rollers arranged in a pyramid-shaped formation.

1 piece cone model the cone as a solidbody revolved 359.9deg. Convert to sheet metal by selecting an edge. Leaving the gap allows it to be converted to sheetmetal. 2 piece cone can be revolved 180 deg as a solidbody. Lofting cones does not .Our Sheet Metal Cone Rolling Machine offers exceptional quality and style within the Aluminum Sheet category.Purchasing Aluminum Sheets in bulk offers cost savings, ensures consistent quality across products, and allows for customization according to specific requirements. Wholesale suppliers often provide discounts and flexible shipment .W11S-20x3000 hydraulic sheet metal 3-roll cone bending rolling machine Whatsapp/Wechat:0086-18855562809Email:[email protected] Sheet metal rolling machines offer a vast repertoire of techniques designed to cater to diverse applications. Whether it’s the classic 3-roll bending, where the sheet metal is shaped between three rolls, or the intricate cone rolling, where a conical shape is imparted, the versatility of these machines knows no bounds. .

Our sheet metal rolling service offers first class roll-bending and curving, and is ideal for any company requiring smooth radius shapes or sheet metal rolled into cylindrical shapes. We are regularly rolling sheet metal, starting from just a few millimetres wide. And with our range of equipment we are able to serve even the largest multi .

Buy a wholesale sheet metal cone plate rolling machine for easy and fast bending of metal plates. Visit Alibaba.com for a wide range of plate bending rolls that suits your needs.Rolling – A process that gradually shapes flat metal sheets into curved, cylindrical or conical forms.; Forming – Sheet metal forming is a versatile fabrication technique that transforms flat metal sheets, tubes, and conical shapes into specified structures using bending, stretching, and stamping methods.; Expanding – A metal-forming process that involves altering the shape of a .Pegasus Profiles offers you the benefit of 40 years of metal rolling and forming experience, coupled with the latest technology to ensure that you, our customer, receive the best quality product. Rolling. Plate Rolling up to 3000mm x 20mm; Rolled Cylinders, Bands and Shells; Concentric and Eccentric Cones; Rolled Plate, Flat Bar, Angles and .

Sheet Metal Cone Rolling Machine#bendingmachine #plateroller #metalfabrication Factory Name:Wuxi Smart CNC Equipment Group CO.,LTD.Mobile/Whatsapp/We-chat:00.Rolling capacity covers cylinders, cones, lobster backs, bucket skins, stringers casings, etc; Complex and multi-radius parts; 100% material traceability; T: +61 3 9706 5100 E: [email protected]. 5 Kitchen Road, Dandenong

As the sheet metal passes through the rolls, it is gradually formed into the desired shape. Section rolling machines are ideal for producing channels, angles, beams, and other intricate shapes. Cone Rolling Machines. Cone rolling machines are specifically designed for forming conical shapes in sheet metal.

In Cone Rolling Machine, while using plate rolling machine products to create cones, we must apply certain methods and talents; however, we may also utilize the cone auxiliary device for auxiliary processing.This article will cover the cone and auxiliary machine production process, as well as how to cope with cracks in the rolling process. Rolling a cone becomes a simple chore .

Cone Calculator is used for all types of Cones Flat Pattern Layout Calculations or Cone Fabrication Layout Development for cones fabrications. . Pressure Vessel Manufacturing Industry, Piping Industry, Sheet Metal Industry, Heavy Equipment Fabrication Industry or any similar Industry. This app helps to Fabrication Engineer, Fabrication Fitter .

Australia’s plate rolling and sheet metal fabrication specialists. Bendworx’s experienced, dedicated team knows how to deliver your next production on time. About; Services. . accurate and quality-assured plate rolling in Brisbane, turns steel into cylinders, cones, tanks, skins, strakes,, stringers, helixes, and much more.

35mm 1 gang + 1 gang + 1 gang metal back box with 1 adjustable lug and 4 fixed lugs. Galvanised steel construction and solid brass earth .

sheet metal cone rolling|cone weight calculator in kg