cnc machine n codes Check out our guide to every CNC code including multiple examples to help you learn the best way to use each code. Consider upgrading your electrical panel for a budget-friendly fix that slashes energy bills and boosts safety and efficiency. This proactive step ensures a more reliable and cost-effective electrical system, shielding your finances while enhancing overall performance and peace of mind.

0 · g code explained with examples

1 · g code commands cheat sheet

2 · g and m code cheat sheet

3 · cnc turning g code list

4 · cnc machine codes list

5 · cnc g code cheat sheet

6 · cnc g code chart

7 · cnc code list pdf

View Ed Wiley’s profile on LinkedIn, a professional community of 1 billion members.

Explore our beginner-friendly guide to the N CNC Code. Start your journey with our step-by-step tutorial and easy-to-follow visuals.Check out our guide to every CNC code including multiple examples to help you . N-Code and its Purpose. N-codes are a type of letter code used in G-code programs for CNC machines. They typically start with the letter “N” and are followed by a number to uniquely identify a block of code. This number . Below is a list of the most commonly used letter codes when programming on a milling center. However, I recommend reading through your machine’s manual to confirm that .

Check out our guide to every CNC code including multiple examples to help you learn the best way to use each code. N-Code. The N-Codes are the names or titles of a block of G-Code. In other words, the line number. For more, see our article on g-code program format. Negative Rake. Rake is the angle from the workpiece wall to .

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide) In this article, we will navigate through the complexities of CNC programming by offering a detailed G-Code and M-Code reference.

tool box ball bearing metal drawer slides

CNC programming is essential for transforming ideas into tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool . Looking for CNC Programming, CNC Machine Programming, CNC G-Codes, or Examples in pdf form to download and study? As great as the world wide web is, sometimes it’s nice to have pdf’s that you can download, print, . Explore our beginner-friendly guide to the N CNC Code. Start your journey with our step-by-step tutorial and easy-to-follow visuals. N-Code and its Purpose. N-codes are a type of letter code used in G-code programs for CNC machines. They typically start with the letter “N” and are followed by a number to uniquely identify a block of code. This number acts as line number and helps the programmer to keep track of his code.

Below is a list of the most commonly used letter codes when programming on a milling center. However, I recommend reading through your machine’s manual to confirm that they have the same function, or if your machine uses different letters/codes. N-codes: These keep track of machine code for manually written conversions. They’re not needed if you’re using CAM software to write and convert instructions. S-codes: These are for the different spindle speeds that the CNC machine will need to reach, maintain, and switch between. (It’s easy to remember, too: S = spindle speed!) Check out our guide to every CNC code including multiple examples to help you learn the best way to use each code. N-Code. The N-Codes are the names or titles of a block of G-Code. In other words, the line number. For more, see our article on g-code program format. Negative Rake. Rake is the angle from the workpiece wall to the cutting tool at the cutting edge. If it is 90 degrees, the edge is perpendicular to the workpiece.

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

In this article, we will navigate through the complexities of CNC programming by offering a detailed G-Code and M-Code reference.

CNC programming is essential for transforming ideas into tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow. Looking for CNC Programming, CNC Machine Programming, CNC G-Codes, or Examples in pdf form to download and study? As great as the world wide web is, sometimes it’s nice to have pdf’s that you can download, print, and hold in your hand. Explore our beginner-friendly guide to the N CNC Code. Start your journey with our step-by-step tutorial and easy-to-follow visuals. N-Code and its Purpose. N-codes are a type of letter code used in G-code programs for CNC machines. They typically start with the letter “N” and are followed by a number to uniquely identify a block of code. This number acts as line number and helps the programmer to keep track of his code.

Below is a list of the most commonly used letter codes when programming on a milling center. However, I recommend reading through your machine’s manual to confirm that they have the same function, or if your machine uses different letters/codes.

N-codes: These keep track of machine code for manually written conversions. They’re not needed if you’re using CAM software to write and convert instructions. S-codes: These are for the different spindle speeds that the CNC machine will need to reach, maintain, and switch between. (It’s easy to remember, too: S = spindle speed!) Check out our guide to every CNC code including multiple examples to help you learn the best way to use each code. N-Code. The N-Codes are the names or titles of a block of G-Code. In other words, the line number. For more, see our article on g-code program format. Negative Rake. Rake is the angle from the workpiece wall to the cutting tool at the cutting edge. If it is 90 degrees, the edge is perpendicular to the workpiece.

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

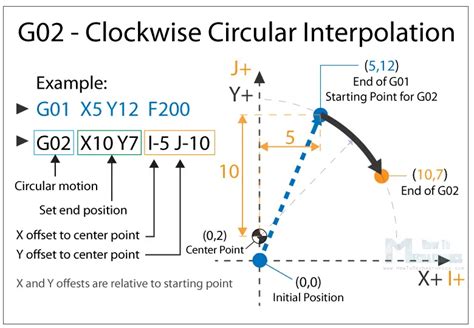

In this article, we will navigate through the complexities of CNC programming by offering a detailed G-Code and M-Code reference. CNC programming is essential for transforming ideas into tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow.

g code explained with examples

Not gonna work with a metal roof. Oh. and don't plan any wire antennas near the metal roof. stick with verticals and mount them on the roof. If you are doing wire antennas they should be far away from large masses of .

cnc machine n codes|g code explained with examples