copper brass sheet metal spinning parts Using quality materials such as brass, copper, stainless steel, aluminum, and cold rolled steel, we can deliver completely finished pieces that meet the needs of your architectural project. Using our hydroform machine and metal stamping . Individual electrical wires are generally required to be installed in metal or plastic conduit. The combination of the wires and conduit results in a complete wiring system. On the other hand, a cable is a factory assembly of two or more bare, covered or insulated wires, enclosed in an overall nonmetallic or metallic sheath for physical protection.

0 · metal spinning techniques

1 · metal spinning process

2 · metal spinning machine

3 · metal spinning lathes

4 · metal spinning company

5 · metal craft spinning products

6 · metal craft spinning machine

7 · history of metal spinning

Lenco CNC is leading the way in the alloy wheel repair market. All of our lathes are built in the USA and we provide local service & support. We utilize state-of-the-art technology to bring the .

Metal spinning craftsmen were now able to turn out quality workpieces in brass, copper, aluminum, and even stainless and cold-rolled .Quote for copper parts including copper spinning parts, copper fasteners, copper electrical parts, hose fittings parts, copper switchgear parts. Get a quote! ISO 9001:2015 Certified, RoHS Compliant

Using quality materials such as brass, copper, stainless steel, aluminum, and cold rolled steel, we can deliver completely finished pieces that meet the needs of your architectural project. Using our hydroform machine and metal stamping .We spin hot-rolled steel, cold-rolled steel, aluminum alloys, copper, brass, and stainless steel alloys, as well as other alloys and metals.Wenzel leads the metal spinning industry by producing custom concentric and symmetrical metal parts in production quantities. This process can be performed by manually by hand or by a .Choose between aluminum, brass, copper, or stainless steel for a high-quality metal sphere, hollow ball, or hemisphere with diameters ranging from 3″ to 36″. We create metal-spun bowls .

metal spinning techniques

Copper Metal Spinning. The copper parts produced by P&J Metal Craft are used for lighting, roofing and decorative purposes since copper are a popular alloy that is known for its heat resistant abilities. Copper has excellent elongation (very formable) and doubles its tensile strength when work hardened, but if it hardens before the part is finished then the part must be .Formed metal hemispheres are typically used for applications such as tank ends, protective caps or covers and architectural components such as finials, fountains or fire pits. Materials: steel, galvanized steel, stainless steel, and aluminum. .

Acme metal spins parts in standard and exotic materials including various alloy steels, stainless steel, aluminum, copper, brass and precious metals. Diameter sizes range from 1/4 inch to 120 .Metal spinning craftsmen were now able to turn out quality workpieces in brass, copper, aluminum, and even stainless and cold-rolled steel. Traditionally, metal spinning has been associated primarily with low volume production, chiefly due to the requirement for highly skilled human operators in a trade with a rather steep learning curve.Quote for copper parts including copper spinning parts, copper fasteners, copper electrical parts, hose fittings parts, copper switchgear parts. Get a quote! ISO 9001:2015 Certified, RoHS CompliantUsing quality materials such as brass, copper, stainless steel, aluminum, and cold rolled steel, we can deliver completely finished pieces that meet the needs of your architectural project. Using our hydroform machine and metal stamping techniques, we .

We spin hot-rolled steel, cold-rolled steel, aluminum alloys, copper, brass, and stainless steel alloys, as well as other alloys and metals.Wenzel leads the metal spinning industry by producing custom concentric and symmetrical metal parts in production quantities. This process can be performed by manually by hand or by a CNC lathe , and is a cost-effective alternative to low volume or short run metal stamping .Choose between aluminum, brass, copper, or stainless steel for a high-quality metal sphere, hollow ball, or hemisphere with diameters ranging from 3″ to 36″. We create metal-spun bowls to fulfill custom orders that call for strong, sturdy metal construction.

Copper Metal Spinning. The copper parts produced by P&J Metal Craft are used for lighting, roofing and decorative purposes since copper are a popular alloy that is known for its heat resistant abilities. Copper has excellent elongation (very formable) and doubles its tensile strength when work hardened, but if it hardens before the part is finished then the part must be annealed to prevent shearing and cracking. Brass is a copper-zinc alloy and has similar properties to copper in its formability but brass work hardens less and requires more force.

Formed metal hemispheres are typically used for applications such as tank ends, protective caps or covers and architectural components such as finials, fountains or fire pits. Materials: steel, galvanized steel, stainless steel, and aluminum. Special or .

Acme metal spins parts in standard and exotic materials including various alloy steels, stainless steel, aluminum, copper, brass and precious metals. Diameter sizes range from 1/4 inch to 120 inches. Acme is continually challenged with new materials, shapes and sizes.Metal spinning craftsmen were now able to turn out quality workpieces in brass, copper, aluminum, and even stainless and cold-rolled steel. Traditionally, metal spinning has been associated primarily with low volume production, chiefly due to the requirement for highly skilled human operators in a trade with a rather steep learning curve.Quote for copper parts including copper spinning parts, copper fasteners, copper electrical parts, hose fittings parts, copper switchgear parts. Get a quote! ISO 9001:2015 Certified, RoHS Compliant

Using quality materials such as brass, copper, stainless steel, aluminum, and cold rolled steel, we can deliver completely finished pieces that meet the needs of your architectural project. Using our hydroform machine and metal stamping techniques, we .We spin hot-rolled steel, cold-rolled steel, aluminum alloys, copper, brass, and stainless steel alloys, as well as other alloys and metals.Wenzel leads the metal spinning industry by producing custom concentric and symmetrical metal parts in production quantities. This process can be performed by manually by hand or by a CNC lathe , and is a cost-effective alternative to low volume or short run metal stamping .Choose between aluminum, brass, copper, or stainless steel for a high-quality metal sphere, hollow ball, or hemisphere with diameters ranging from 3″ to 36″. We create metal-spun bowls to fulfill custom orders that call for strong, sturdy metal construction.

Copper Metal Spinning. The copper parts produced by P&J Metal Craft are used for lighting, roofing and decorative purposes since copper are a popular alloy that is known for its heat resistant abilities. Copper has excellent elongation (very formable) and doubles its tensile strength when work hardened, but if it hardens before the part is finished then the part must be annealed to prevent shearing and cracking. Brass is a copper-zinc alloy and has similar properties to copper in its formability but brass work hardens less and requires more force.Formed metal hemispheres are typically used for applications such as tank ends, protective caps or covers and architectural components such as finials, fountains or fire pits. Materials: steel, galvanized steel, stainless steel, and aluminum. Special or .

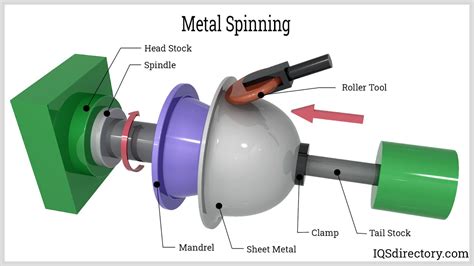

metal spinning process

metal spinning machine

metal spinning lathes

cnc laser cloth cutting machine factory

Only one grounded wire per terminal is allowed in most cases in a panelboard (do not put the white and bare in the same hole). I think is looks cleaner when the white and bare follow the same path and land on adjacent screws.

copper brass sheet metal spinning parts|metal spinning lathes