projection welding sheet metal Projection welding is great for joining sheet metal parts where multiple welds are needed in a confined space. It’s often used in making metal enclosures, brackets, and frames. . The best box spring brings height to the bed, enhances breathability, and extends the life of your mattress. See shopping tips and top picks.

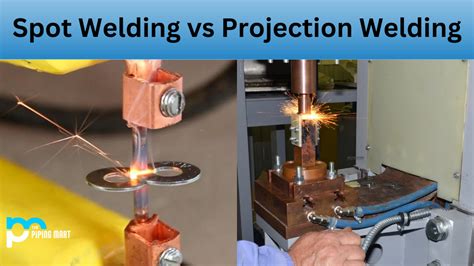

0 · projection welding vs spot welding

1 · projection welding vs spot

2 · projection welding symbol

3 · projection welding pdf

4 · projection welding parameters chart

5 · projection welding electrodes

6 · projection weld callout

7 · disadvantages of projection welding

$9.99

Projection welding is a form of resistance welding that uses pressure and electric current to join two or more metal parts. It uses raised sections or "projections" on one of the . A key attribute of projection welding is the ability to get rid of plating on the surface and expose parent metal on both sides for a direct bond. Plating material often interferes with .

What is a Projection Weld? Projection welds developed via the resistance welding (RW) process use the design or shape of the part to make discreet individual-point contacts to .As with resistance spot welding in automotive applications, projection welding also is used to join two overlapping sheets of relatively thin metal. The process involves pressing a projection or number of projections in one of the plates . Projection welding is great for joining sheet metal parts where multiple welds are needed in a confined space. It’s often used in making metal enclosures, brackets, and frames. .

Projection welding, also known as resistance fastener welding, is the most common method for nut and M- or T-thread bolt welding. This article examines recent experiments with projection welding of those components to . Projection welding allows for rapid and precise joining of metal sheets, ensuring high productivity and consistent quality in production processes. Projection welding is a .

Projection welding is a variation of spot welding. It is primarily used for welding low carbon steel and low alloy steel stamping parts. The ideal thickness range for projection welding of a plate is between 0.5 and 4mm, .

Differences in material compositions, strengths, hardnesses, and new coatings can increase demand on equipment and contribute to subpar results. Compared to easier-to-weld mild and high-strength/low-alloy material, . A long-established welding process, RPW is commonly used to weld either parts of different sizes, such as flanges to sheet metal, or parts with different material properties, such as copper to steel. RPW creates heat .

projection welding vs spot welding

metal handy boxes

Both spot and projection weld fasteners have their place. Spot welding fasteners resistance-weld directly to a sheet with either a rocker-arm or a press-type resistance welding system (see Figure 1 and Figure 2).Projection fasteners, which have small protrusions on the surface that fuse to the base metal, require a press-type machine.The method can also be used for welding metal sheet to the ends of bars, rods or pipes, or for welding bolts, nuts, and other attachments to sheets. Such attachments are being used widely in the automotive industry. . As noted, .

Coined or machined projections do not cause the same concerns as a stamped projection, as there is no risk of premature projection collapse during welding. The shape and size of coined or machined projections are . Sheet metal works often employ projection welding to join metal sheets and create larger structures. Other notable applications include welding parts for refrigerators, grills, and condensers. “Projection welding is a valuable technique with .Welding parameters. Welding parameters depend on the nut type, size and sheet thickness to be welded. As an example for square nuts to BS 7670, the following conditions for welding to 1mm sheet may be used as a guide to setting up.

Projection welding machines apply the current and weld forces on these predetermined weld points, unlike spot welding where the weld is determined by the size or shape of the electrode. These Projections can be produced by embossing on sheet metal, machining or cold forging on a solid piece and press punch on the edge of a piece. The article contains the analysis of projection welding in relation to the non-parallel location (non-parallelism) of electrodes. For a thin-walled flat element, e.g., sheet metal with two embossed projections, calculations were conducted for different angles between the upper electrode and the lower electrode. The calculation involved the use of the SORPAS 3D .

metal gear solid x box

Cunningham A, Begeman ML (1965) A fundamental study of projection welding using high speed photography. Weld J 44(4):381–384. Google Scholar Gould JE, Workman D, Raynes C (1998) An examination of projection welding coated sheet steels. In: Proceedings of the 8th Sheet Metal Welding Conference, Troy, Michigan, pp 137–142The chance to weld thick pieces of metal . What projection welding is used for. Due to its advantages, projection welding is most used in the electrical, automotive, and construction fields for: Fastening attachments such as weld nuts, brackets, spigots to sheet metal in all the cases where there is access from only one sideABOUT SKV. SKV Automotive manufactures a wide range of high quality, precision engineered automotive parts. With over 25 years of production expertise, the company is a well known name in north India in friction products like brake pads backplates, unlined brake shoes, levers and automotive sheet metal components.Minifaber offers sheet metal welding services according to the customer's specifications: MIG welding, TIG welding, resistance welding, projection welding, robotic MIG and TIG welding and laser welding on various metallic and aluminum alloy surfaces.

Projection welding uses the same process as spot welding whereby two electrodes create resistance and generate heat. However, in projection welding, the electrodes are flat and the weld area is localised by projections (raised areas) in the workpiece. . If you have a question regarding welding or any other sheet metal processes, or are .Sheet metal parts are formed on our CNC press brakes . TIG, and Resistance (Spot, Projection) welding processes to make aluminum, stainless and carbon steel weldments, as well as complex fabricated assemblies. Learn More. About TMF Metal Solutions. TMF Metal Solutions has proven systems, trained staff, and the latest technology in place to .

A new Mamdani-type fuzzy inference system with four input variables such as weld current, electrode force, a transformed variable of weld time + sheet thickness, and projection height was proposed . When it comes to resistance welding, projection welding and spot welding are two commonly used techniques. They may seem similar at first glance, but each has. . While this works well for general sheet metal welding, it doesn’t offer the same level of precision as projection welding. If you need multiple welds that are close together, spot .Sheet Metal Shielded Metal Arc Welding Shielding Gases Soldering Stainless Steel Steel (See Also Carbon Steel, Stainless Steel, Structural Welding) Structural Welding Stud Welding . WHC3.02 PROJECTION WELDING .

Applications: Spot / Projection Welding, Electro-Brazing, Cross Wire Welding, Sheet Metal- 2-ply or Multi-ply, Mark-less Welding, Resistance Heating and Soldering. Capable of Welding Low Carbon Steel,High Carbon Steel,High Strength Steel,Nickel Alloy,High-Temp Alloy,Titanium. Confirmation of weldability of other materials can be provided on .Projection welding. Images and videos of resistance welding parts with projections to balance heat and create stronger welds. Spud welding. PRODUCTS. . Sheet Metal. End Product. Air Springs. Resistance Welding - Spud Fitting Case. View Product Learn More. Application Details. Power Supply | Alt. Power Supply. IS-300CA. Weld Head or Focus Head .Welding Capability: sheet metal up to 3mm thickness or M10 nut projection welding; Nut and bolt welding electrode/ tooling are available upon request; Auto Nut Feeder and Nut Detector avaliable upon request; 2 step cylinder reduce spot welding cycle time while giving enough space for electrode changeover Welding obtained is uniform and appears better than spot welding. Limitations of Projection Welding. The initial cost is high as press type machines are required for this type of welding. This process is economical only for large scale production. Brass and copper cannot be projection welded. Applications of Projection Welding. In sheet metal .

A long-established welding process, RPW is commonly used to weld either parts of different sizes, such as flanges to sheet metal, or parts with different material properties, such as copper to steel. RPW creates heat balance at the weld interface of dissimilar materials so that both parts get equally hot at the same time, notes Kelkar.

Spot welding fasteners resistance-weld directly to a sheet with either a rocker-arm or a press-type resistance welding system (see Figure 1 and Figure 2). Projection fasteners, which have small protrusions . During the weld, the extra metal within each projection heats up into a liquid nugget, which in turn helps control and focus heat to .

Sheet Metal Distortion. Problems with weld force, fixture placement and access to weld areas may cause distortion in workpieces and stampings. . Guide is written for operators and engineers to help diagnose and solve common spot welding defects and issues, projection welding and seam welding applications. Consider it an experienced second .

Projection welding finds applications in various industries such as automobile, shipbuilding, sheet metal works, and the welding of parts in refrigerators, grills, and condensers. The process creates discreet point contacts to concentrate current during welding and the projections collapse as the weld nugget forms, holding the parts together .Manufacturer of PROJECTION WELDING - Pedal Operated Stainless Steel Spot Welding Machine, MSC Spot Welding Machine, Rated Input Power: 1 KVA - 20 KVA, Pneumatic Operated Spot Welding Machine, For Metal Sheet Joint, Rated Input Power: 50kVA offered by Rajlaxmi Electricals Private Limited, Rajkot, Gujarat.

9. Projection Welding In Projection welding size and shape of individual welds are determined by the presence of projections, embossments or intersections on the metals to be joined. Metals are heated and coalescence is achieved not through the use of an arc, but through the metals’ resistance to electrical currents passing through them as they are held together .tests - Part 12: Spot, seam and projection welding (ISO/DIS 15614-12:2000). prEN ISO 15614-13, Specification and qualification of welding procedures for metallic materials - Welding procedure test - Part 13: Resistance butt and flash welding (ISO/DIS 15614-13:2002).

projection welding vs spot

metal gear solid wiki cardboard box

$292.43

projection welding sheet metal|disadvantages of projection welding