sheet metal bending 101 You can do a lot with only a handful of tools. Even still, it can be pretty easy to mangle if you don’t use the right technique. Here are a few tips that will let you . $49.45

0 · types of sheet metal bending

1 · sheet metal fabrication design guide

2 · sheet metal bending guidelines

3 · sheet metal bending guide pdf

4 · sheet metal bending diagram

5 · sheet metal bending design guidelines

6 · sheet metal bending design guide

7 · maximum thickness sheet metal bending

Wildcat Industries is the leading provider of sheet metal in Melbourne, specializing in custom perforated panels for various sectors, such as architecture, building, construction, interior design, and landscaping.

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending . Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the .You can do a lot with only a handful of tools. Even still, it can be pretty easy to mangle if you don’t use the right technique. Here are a few tips that will let you . You’ll learn how to tackle common challenges, ensuring high-quality, efficient production. Whether you’re a seasoned technician or a curious beginner, this guide offers valuable insights to enhance your understanding .

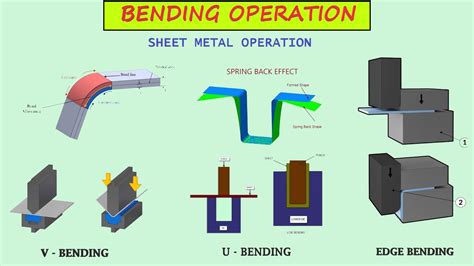

Fundamental Processes in Sheet Metal Forming Bending. Bending involves applying force to a sheet metal piece to bend it at a specific angle and radius, creating V, U, or channel shapes. Bending is crucial for manufacturing components with geometric precision and is widely applied in creating brackets, enclosures, and frames. As the bender moves down, the rocker makes contact with the sheet metal. One contact point acts as a holding pad, while the opposite contact point rotates, creating the bending action. After the bend is completed and on . Using a brake machine, a sheet metal fabricator can bend sheet metal in channels to the angle of up to 120 degrees and into U and V shapes. The malleable thinner gauges of sheet metal are easier to bend. Sheet metal .

/ Blog / Electronic Enclosure Design 101 – Sheet Metal Design Guide Electronic Enclosure Design 101 – Sheet Metal Design Guide . 2017-02-16 . Bending metal and bend radius. Sheet metal enclosures and parts are bent with a press brake or a folder. The metal typically cannot be formed into a true 90-degree edge, but rather, the corners . Steel Bending 101: Techniques for Strength and Precision . In this blog, you will learn about sheet metal bending, the process, how precision is achieved, and why one must hire only reputed . Aluminum Bending Methods. Bending aluminum involves various methods suited to different projects and material properties. Here’s a rundown of the most common aluminum bending methods: 1. Press Brake Bending. Description: A press brake uses a punch and die to create bends in aluminum sheets. The aluminum is placed on a lower die, and a punch .

types of sheet metal bending

Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and fracturing in hard material. Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part.While riveting onto sheet metal parts, you must prioritize the alignment of the riveting nuts. Sheet Metal Bending. Folding 2D flat sheet metal transforms the pieces into 3D. Finishing the processing requires a folding bed and a bending mold, and the bending procedure follows a specific order and involves several steps.Sheet metal fabrication is a process of shaping and designing metal sheets in a cost-effective manner. Various techniques such as cutting, punching, bending, etc are used for the fabrication process which ensures production of robust fabricated materials with better metal finishes.. Today, all the major industries such as the automotive industry, aerospace industry, agricultural .

Die Basics 101: Bending methods--Wipe, coin relief, pivot, V bending. By Art Hedrick; Updated July 18, 2018; August 8, 2007; Article; . Both compression and tension occur when bending sheet metal. The inside radius of the bent metal is in compression, or being squeezed together. The outside bend radius is in tension, or being stretched. Die Basics 101: Metals used in stamping (Part 2 of 2) By Art Hedrick; Updated July 18, 2018; June 13, 2006; . The metal's mechanical properties greatly influence the process chosen to transform the flat sheet metal into the finished part's shape and profile. The mechanical properties often influence the tool steel and lubricants used to form .

solidworks for sheet metal design

101 terms. azezs. Preview. ARH Exam 2 Slide ID's. 20 terms. Lanie_Pelegrino23. Preview. Materials and Specs. 86 terms. emmaeitzen. Preview. Exam 3 Study Guide. 114 terms. . the line at which the metal starts to bend and the line at which the metal stops curving. Bend Allowance. the amount of material consumed in making a bend. Blanking—A dual-purpose cutting operation usually performed on a larger scale, blanking is used in operations in which the slug is saved for further pressworking.It also is used to cut finished piece parts free from the sheet metal. The profiled sheet metal slug removed from the sheet by this process is called the blank, or starting piece of sheet metal that will be cut or .Welcome to Architectural Sheet Metal 101, your one-stop-shop for mastering the art of exterior sheet metal installation. With over 19 years of hands-on experience, we're here to guide you through . (A press brake is a simple machine employed in sheet metal bending processes, it forms desired bends on the sheet by working to clamp the sheet metal in position for press between the punch and the die) Roll Bending. .

The relationship between the bending radius of sheet metal and the width of the lower die groove of the bending die has been established through numerous experiments in sheet metal processing.. For example, when a .Procurement 101: An Introduction to Sheet Metal Fabrication Process. . Roll forming involves gradual bending of sheet metal through a series of contoured rollers. As the sheet metal passes through the rollers, it takes on the shape of the rollers to form the desired bends and curves. This process is ideal for producing parts with long bends .Three sizes of sheet metal bending pliers for your selection: straight jaw, 45 degree jaw, 90 degree jaw. These hand seamers are 2-3/8'' (60mm) wide. . Architectural Sheet Metal 101 . Videos for this product. 4:20 . Click to play video. BILITOOLS 3-Piece Sheet metal Bending/Seaming Pliers .

Part I of this series focused on the various careers in the metal stamping industry. Part II discussed stamping materials and equipment; Part III focused on dies and cutting and Part IV offered more detail about cutting processes. The final installment, Part V, investigates forming methods. Methods for Forming Sheet Metal Bending

Hello everyone! You are watching video "Make A Simple Sheet Metal Bending Tool- DIY Projects"Learn how to create a simple sheet metal bending tool with this. Sheet metal bending is a transformative process that reshapes flat sheets of metal into desired profiles by applying force, typically without altering the material’s volume or thickness. This procedure is a cornerstone of many manufacturing and construction projects, allowing for the creation of intricate components and structures from simple .Welcome to Architectural Sheet Metal 101, your one-stop-shop for mastering the art of exterior sheet metal installation. With over 19 years of hands-on experience, we're here to guide you through .C- Distance between Emboss and Sheet Metal bend = 3T + R + D/2. Dimple Feature Design in Sheet Metal Parts. Louver Feature Design in Sheet Metal. The minimum distance between the louver feature and bending edge is maintained to avoid metal deformation. (P1) Distance Between Two lowers on Shorter Edge = 5 mm

Each time the metal is rolled, it gets thinner and thinner. The space between the final set of rollers determines the final metal thickness. After the desired thickness is obtained, the sheet metal then is rolled into a large coil. Typical sheet metal thicknesses used in stamping are 0.001 in. to 0.625 in. 101 likes, 0 comments - cnc_love2 on November 16, 2024: "Our factory can produce any metal parts, stamping parts, mold manufacturing, forging parts, sheet metal bending, laser cutting, automobile parts, motorcycle parts and bicycle parts. Friends who .

Electrical Enclosure Bending; Electrical Enclosure Welding; Electrical Enclosure Polishing; . Aerospace Sheet Metal Fabrication 101: A Basic Knowledge Guide. By KDMFAB / May 30, 2024 . From choosing suitable material to precision sheet metal fabrication, fabricating aerospace sheet metal parts can be challenging. The best part, today’s . Press Brake Bending Basics (A Guide to Sheet Metal Bending) 45 Press Brake Terminology You Should Know; Press Brake Fundamentals. Press brakes are indispensable machines in the metal fabrication industry, enabling precise bending and forming of sheet metal to create a wide range of structures and components.

sheet metal fabrication design guide

soluciones metalmecanicas

sound proof junction box finished wall

Our Modular Drawer Cabinets are designed with flexibility in mind. Choose from a vast offering of preconfigured cabinets or customize your cabinets on the fly. With one-piece welded construction, our Modular Drawer Cabinets are the perfect solution for the organization of small and large items.

sheet metal bending 101|maximum thickness sheet metal bending