deep junction box in my ductwork made of fiberboard With the exception of not properly securing the conduits within 12" of the junction box, is installing the junction box on the duct like this acceptable? The way I see it it's done all . Any suggestions on how to treat the current pinholes in preparation for epoxy and paint? Should I drill them out and weld up the holes? Will the epoxy be sufficient to fill these in? Or should I put a skim coat of filler over them after epoxy? I'm .

0 · sealing sheet metal ducts

1 · sealed fiber duct seam

2 · sealed fiber duct sealant

3 · sealed fiber board ducts

4 · junction box on duct

5 · insulated fiber ducts

6 · insulated fiber duct installation

Welding thin sheet metal requires patience, precision, and an understanding of the material properties. We are proud to have mastered these challenges at Shengen and pushed the limits of sheet metal fabrication. Our commitment to innovation and quality guides every step, from selecting the right equipment to setting up the workspace. .Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn .

Some contractors are recommending removing/replacing the trunk line (which is made of sheet metal and insulated on the inside) with 2 "distribution boxes". Not really sure what that is. They say the old trunk line is probably .

With the exception of not properly securing the conduits within 12" of the junction box, is installing the junction box on the duct like this acceptable? The way I see it it's done all . We are installing ductwork in our house that previously had none as it was heated by baseboard boiler heat. The contractors routinely use this fiberboard (fiberglass?) to form the .Fabricate and install the fiber board ducts. To seal seams, use outward-clinched staples and UL-181A-approved metal tape that is heat activated or pressure sensitive or use mastic and fiber . If you need to replace the ductwork in your home or you’re building a new home, you should think carefully about what type of ductwork you want to use. There are four main .

While there are a number of advantages to fiberboard duct, including low cost, ease of installation and less risk of injury during installation than metal duct, there also are a number of problems. .Material – Fiberboard ducts are a type of HVAC duct that uses compressed fiberglass fibers bonded with resin to insulate against heat loss. Sound dampening – Like fiberglass lined .

The 3 gang junction box is arguably going to be obstructed by the 8" rigid duct. How important is it to address this? Thoughts on each of these below View up towards attic from .I’m in the beginning stages of planning my basement finish and I discovered 2 junction boxes mounted above my HVAC ducts. I will be adding a soffit to that area and drywall over it. Am I .

Find out why metal ducting should not be noisy if it is installed properly. Get tips on having your fiberboard ductwork replaced with metal ductwork and having the contractor build in a place .

Some contractors are recommending removing/replacing the trunk line (which is made of sheet metal and insulated on the inside) with 2 "distribution boxes". Not really sure what that is. They say the old trunk line is probably very dirty. With the exception of not properly securing the conduits within 12" of the junction box, is installing the junction box on the duct like this acceptable? The way I see it it's done all of the time. Some duct equipment even comes with JB's mounted to it. We are installing ductwork in our house that previously had none as it was heated by baseboard boiler heat. The contractors routinely use this fiberboard (fiberglass?) to form the duct work instead of the regular old metal ductwork.

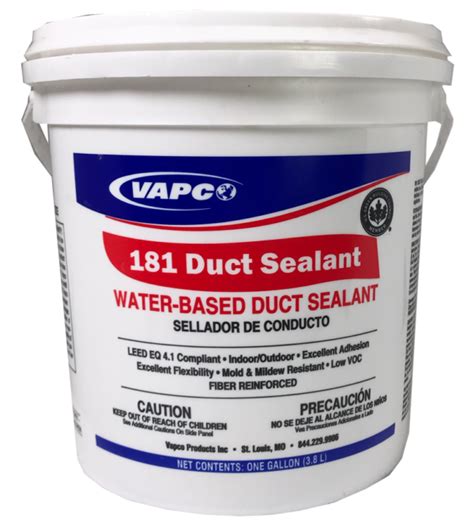

Fabricate and install the fiber board ducts. To seal seams, use outward-clinched staples and UL-181A-approved metal tape that is heat activated or pressure sensitive or use mastic and fiber mesh tape. Use screws to secure connections to sheet metal collars, duct boots, or trunk lines. If you need to replace the ductwork in your home or you’re building a new home, you should think carefully about what type of ductwork you want to use. There are four main types of ductwork commonly used in HVAC systems: sheet metal ducts, flexible ducts, fiberboard ducts and fiberglass ductboard.While there are a number of advantages to fiberboard duct, including low cost, ease of installation and less risk of injury during installation than metal duct, there also are a number of problems. Troubles with fiberboard ducts can occur if they are not properly maintained or installed.Material – Fiberboard ducts are a type of HVAC duct that uses compressed fiberglass fibers bonded with resin to insulate against heat loss. Sound dampening – Like fiberglass lined ductwork, fiberboard ducts are also very effective at reducing operation HVAC system noise.

I have been doing some work in a newer development where all of the hvac equipment and duct work is in the attic. Whoever did the ductwork used triangle duct boxes. They used 10 inch supllies off of the plenum of the furnace . The 3 gang junction box is arguably going to be obstructed by the 8" rigid duct. How important is it to address this? Thoughts on each of these below View up towards attic from cabinet. Ignore the 12/2 Romex, I'm using it to mark the cabinet's location in the attic. I’m in the beginning stages of planning my basement finish and I discovered 2 junction boxes mounted above my HVAC ducts. I will be adding a soffit to that area and drywall over it. Am I right in assuming that I need to move those boxes down so they are exposed? Some contractors are recommending removing/replacing the trunk line (which is made of sheet metal and insulated on the inside) with 2 "distribution boxes". Not really sure what that is. They say the old trunk line is probably very dirty.

With the exception of not properly securing the conduits within 12" of the junction box, is installing the junction box on the duct like this acceptable? The way I see it it's done all of the time. Some duct equipment even comes with JB's mounted to it. We are installing ductwork in our house that previously had none as it was heated by baseboard boiler heat. The contractors routinely use this fiberboard (fiberglass?) to form the duct work instead of the regular old metal ductwork.

Fabricate and install the fiber board ducts. To seal seams, use outward-clinched staples and UL-181A-approved metal tape that is heat activated or pressure sensitive or use mastic and fiber mesh tape. Use screws to secure connections to sheet metal collars, duct boots, or trunk lines. If you need to replace the ductwork in your home or you’re building a new home, you should think carefully about what type of ductwork you want to use. There are four main types of ductwork commonly used in HVAC systems: sheet metal ducts, flexible ducts, fiberboard ducts and fiberglass ductboard.While there are a number of advantages to fiberboard duct, including low cost, ease of installation and less risk of injury during installation than metal duct, there also are a number of problems. Troubles with fiberboard ducts can occur if they are not properly maintained or installed.Material – Fiberboard ducts are a type of HVAC duct that uses compressed fiberglass fibers bonded with resin to insulate against heat loss. Sound dampening – Like fiberglass lined ductwork, fiberboard ducts are also very effective at reducing operation HVAC system noise.

I have been doing some work in a newer development where all of the hvac equipment and duct work is in the attic. Whoever did the ductwork used triangle duct boxes. They used 10 inch supllies off of the plenum of the furnace .

sealing sheet metal ducts

The 3 gang junction box is arguably going to be obstructed by the 8" rigid duct. How important is it to address this? Thoughts on each of these below View up towards attic from cabinet. Ignore the 12/2 Romex, I'm using it to mark the cabinet's location in the attic.

aloha sheet metal

What is the best way to weld 24 Gauge steel with a MIG welder? I can weld a number of spot welds with out burning through, When the steel is butted together. I use a miller 200 set Low, 40 amps.

deep junction box in my ductwork made of fiberboard|insulated fiber ducts