wake up client board does not reply cnc router parts I can not get past the screen that prompts you with CTFTP::Wake up client board dows not reply. I clicked "no" and put in 10.9.9.9 and it simply won't connect. I installed plugin . $9.99

0 · ctFTP::WakeUpClient Board does not reply

1 · WakeUpClient Board does not reply.

2 · Wake up client board does not respond

3 · Mach3 Control Board Troubleshooting Guidance

4 · Mach 3 StartUp Message

5 · General Off Topic Discussions > WakeUpClient does not reply

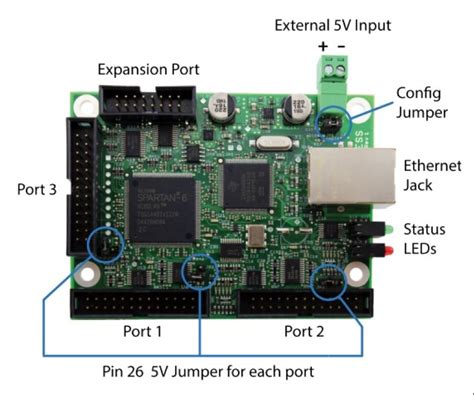

6 · Ethernet SmoothStepper

7 · DIY CNC Router Table Machines > Ethernet SmoothStepper

8 · CTfp:: wake up client board does not respond

9 · CNC WakeUpClient Error

$80.78

Another thing is go to the back up folder(xmibackups) in the Mach folder and find the next to last date change and copy that to the Mach folder. The last one is when you added . I can not get past the screen that prompts you with CTFTP::Wake up client board dows not reply. I clicked "no" and put in 10.9.9.9 and it simply won't connect. I installed plugin .

I started getting this error message "ctFTP::WakeUpClient Board does not reply" randomly, usually I could reboot the computer and the ESS and everything was fine for a little . I can not get past the screen that prompts you with CTFTP::Wake up client board dows not reply. I clicked "no" and put in 10.9.9.9 and it simply won't connect. I installed plugin . Just started today after cutting for a while. When I start Mach 3 I get the message "Wake up Client Board does not reply". I have tried rebooting, new cables, Any ideas of what . All I get is ESS_v10r2d1d/ CTftp::WakeUpClient Board does not reply. I have tried everything including reinstalling it on a laptop with Windows 7. What I have tried

WakeUpClient Board does not reply. This is the place to post more technical questions. If you have the system setup , running and making cuts then something quits .

Wake up client board does not respond This is the place to post more technical questions. If you have the system setup , running and making cuts then something quits .Mach3 Control Board Troubleshooting Guidance. This document works for Mach3 software-based controller such as NVCM/NVUM_SP/NVUM/NVEM/UC300/EC300/EC500. The purpose of this .

The computer was awake, and when I opened Mach3, it popped up with “CTftp::WakeUpClient Board does not reply.” I shut stuff down, unplugged everything, waited, .

New to this so bare with.We're got an AXYZ 4000 Series CNC Router. We use a 10'x5' 18mm thick MDF waste board, which in the past has worked very well, however our supplier has recently said they are only able to get moisture resistant MDF rather than standard. Is there much difference in suction using moisture resistant MDF as to standard MDF?

The people I purchased it from do not know anything about assembly, or Mach3 configurations. I had to do a lot of research for the right configurations. There is a lot of information on the 6040 CNC but nothing on the 6090 CNC. I guess this is a new model.Unplug the power supply, usb cable, and controller directly from the grbl control board. Plug in the power supply. When you push the power button, does the board light turn on, and does the fan spin? If no, check power supply and connection for output and unwanted shorts or disconnects. Does the controller work?

You're absolutely underselling yourself with that pricing, and probably underestimating the hours if it's your first paid job. The "hours you're working" in a self employed scenario include all the communication, setup, run time, cleanup, sanding, trips to go get some tool that broke at the last second, etc, on top of running the business (accounting and that sort of thing). ISSUE or REQUEST: Affected Tool or Resource: CNC Team, Group or Volunteer who usually handles this type of ISSUE or REQUEST (Please tag using the @ symbol. Start by typing @TEAM_ to find most responsible teams): @TEAM_Electronics Details of ISSUE or REQUEST (Please be as specific as possible): I wanted to use the CNC on the 28th. The .

It sounds like the motors are working correctly but the controller is not receiving a command to move the spindle to a new location. Are you actually sending a move command to the controller? Just changing the feed rate does not make the spindle move, it needs to be told the feed rate you want to move and where you want to move the spindle.Making parts for my cnc router with my cnc router. imgur.com Open. Share Sort by: Best. Open comment sort options . be soldering the rotary encoder I bought to the pcb in order to get a knob and use qmk to flash the firmware of the board. Wish me luck ladies and gentleman . new Glorious Panda switches and a freshened up face plate.

I have a problem with a DTHC IV + ethercut system, this has been happening for a while but it's getting more frequent, the machine with the problem uses a MP3500 DTHC IV ethercut system with Yaskawa drives and servo motors, powermax 65 plasma with Hypertherm's voltage divider, and it runs using a home built desktop PC with windows 7 Pro 32 bit . I keep getting a client wake up board does not respond note...running smoothstepper ethernet with win 8...what does that mean and how can i fix it. thanks in advance-Andy. Logged Hood. 25,835; Carnoustie, Scotland; Re: help...client wake up board? « . I have a problem with a DTHC IV + ethercut system, this has been happening for a while but it's getting more frequent, the machine with the problem uses a MP3500 DTHC IV ethercut system with Yaskawa drives and servo motors, powermax 65 plasma with Hypertherm's voltage divider, and it runs using a home built desktop PC with windows 7 Pro 32 bit .

I'm having issues with this thing. I can not get past the screen that prompts you with CTFTP::Wake up client board dows not reply. I clicked "no" and put in 10.9.9.9 and it simply won't connect. I installed plugin version 10H2d1a and 10hd2 both with the same result. I have my computer setup to IP 10.9.9.1 but also tried using 10.9.9.8. I have tried this on a laptop and a .

Garble control board, and I can use Open Builds again. I ordered a water cooled spindle to use with it because I can't stand the screeching router noise. The new CNC should ship on October 14th. I will send pics after the build. While waiting for the CNC, I insulated my garage, the propane wall heater will be delivered today. I have a problem with a DTHC IV + ethercut system, this has been happening for a while but it's getting more frequent, the machine with the problem uses a MP3500 DTHC IV ethercut system with Yaskawa drives and servo motors, powermax 65 plasma with Hypertherm's voltage divider, and it runs using a home built desktop PC with windows 7 Pro 32 bit .

I have been running a lot of long STL files. Some of which are over 8 hours start to finish on the cnc. I need to know what you charge, and how do you calculate the price. Most of my work is fairly small, from 8“ x 22”, to 12” x 24”. My cnc work area is 34” x 34”. I . ESS slow load, Wake up board does not reply, mid stream failure -Debounce Hello Guest it is October 17, 2024, 07:44:27 AM . Very slow to load up if it loads up and most of the time gives wake up client board. This was a good install, firewall down, defender, no security essentials, proper power settings, Windows 7. On another Dell 745 we had .

I’m trying to help my dad get his table back up and running after months of being out of commission. He gets this message in Mach3. The IP address is correct. He’s running all new hybrid servo encoder motors and the smooth stepper board is not turning on in Mach 3. We are needing to purchase new spoil boards for our CNC Router. We have a vacuum table and use the spoil board as a fixture table (making smaller parts but not nested). I am finding mixed answers regarding what type of MDF boards we should purchase. Is ultralight better for our application or is standard MDF the way to go? ctFTP::WakeUpClient Board does not reply This is the place to post more technical questions. If you have the system setup , running and making cuts then something quits working and it has you scratching your head let the experts at CandCNC come to you aid.

My situation is that I’m very experienced with CNC and have near zero luthiery experience. I’m asking here about the very specific details of people’s experience with using tiny bits to make cuts in expensive woods because it’s a very specific task, and particularly with CNC work on hardwood, there’s always one or two little details in how to program the cuts that make the . I have the wires completely separated from my control board wiring. Control board is on the left side my bench top and the spindle inverter box and wiring runs from the right side near my computer. The wiring does not touch. The control board uses a USB connection to the computer and the USB shuts down while running a job. Which is very annoying!I’ve had experience with avid cnc parts on routers as well as reading about them forever, never had a full machine of theirs. I’ve also had experience with stinger 3’s and their customer service. Avid cnc stuff is great, but you have to assemble the machine. Assembly is a pretty important part of the machine. Nice when done by a pro.

ESP32 is a series of low cost, low power system on a chip microcontrollers with integrated Wi-Fi and dual-mode Bluetooth. The ESP32 series employs either a Tensilica Xtensa LX6, Xtensa LX7 or a RiscV processor, and both dual-core and single-core variations are available.I'm new to CNC, but got a position as a CNC opperator at a sign shop cutting HDU a few months ago. We have a Laguna Smart shop 2 using a 5' X 10' vacuum table. We put MDF board down for the spoil board and plane both sides to make it flat and remove the . I cannot vouch for all of them but I am impressed with Centroid Acorn CNC, as I moved to that from Mach 3. If you can trace wires, do some mild electrical work, troubleshoot hardware and software problems, and have the confidence to complete a project I think you will be fine to do a retrofit of a control system on your own.A big disadvantage compared to rigid, overhead X/Y CNC machines is that the sled rides on the material itself, so: you are limited to perfectly flat materials large pocket cuts can trap or hang up the sled -large carvings can create uneven surfaces that allow sled to move below 0 set point on Z-axis, which screws up Z-axis cut depths

Couple years back I got 2 of those cheap Chinese 3 axis CNC routers. the first was missing parts (sent back) and the second had a motor bracket that was 3D printed out of garbage plastic so I began to upgrade the machine. Fast forward to the present and I have a 24" X 39" table with bigger motors and drivers (nema 23). Wake up client board does not respond. This is the place to post more technical questions. If you have the system setup , running and making cuts then something quits working and it has you scratching your head let the experts at CandCNC come to you aid. If it appears to be an electronics problem we will help you troubleshoot it and get you .

ctFTP::WakeUpClient Board does not reply

WakeUpClient Board does not reply.

In American English, Z is pronounced " zee " / ˈziː /, because it comes from a late 17th century English speech. [1] The name of the Semitic symbol was zayin and was the seventh letter. It .

wake up client board does not reply cnc router parts|General Off Topic Discussions > WakeUpClient does not reply