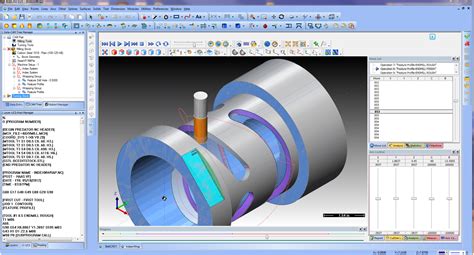

cnc machine autocad drawing Therefore, this article is dedicated to helping you learn how to prepare CAD files for CNC machining. 1. Optimize Tolerances. 2. Type of Material. 3. Minimize the Number of Machined Features. 4. Minimize Machined Stock Allowance. 5. Standardize Features. 6. Surface Finish. 7. Provide Adequate Strength and Stiffness. 8.

The two main materials for the under-the-cabinet and space-saving coffee makers are stainless steel and plastic. Both are hygienic, have good thermal conductivity, and are easy to clean. Pay close attention to build quality, design, and durability when choosing a coffee maker.

0 · free cad software for cnc

1 · free cad cam cnc

2 · cnc AutoCAD free download

3 · cad drawing for cnc machine

4 · auto cad cnc drawing

5 · AutoCAD to cnc machine

6 · AutoCAD cnc software

7 · AutoCAD cnc programming

Shop Windster Hoods 36 inches Externally Vented Under cabinet Range Hood Stainless Steel at Best Buy. Find low everyday prices and buy online for delivery or in-store pick-up. .

On this episode of Make It Kustom, I walk you through drawing a part in AutoCAD to CNC plasma cutting the part. This is meant to be a introduction to the pro. Hello friends, from today we are going to start back to back CNC programming, so friends, we need CNC programming, first AutoCAD drawing, then first we made . In this series of videos I walk through the full process of designing and cutting a part to be cut on a CNC router. In part one I do the basic CAD design wo. CNC machining drawings are the blueprints for precisely manufactured operations that ensure the accuracy and efficiency at the core of the process. These intricate drawings determine the dimensions, shape, and .

On this episode of Make It Kustom, I walk you through drawing a part in AutoCAD to CNC plasma cutting the part. This is meant to be a introduction to the pro. Therefore, this article is dedicated to helping you learn how to prepare CAD files for CNC machining. 1. Optimize Tolerances. 2. Type of Material. 3. Minimize the Number of Machined Features. 4. Minimize Machined Stock Allowance. 5. Standardize Features. 6. Surface Finish. 7. Provide Adequate Strength and Stiffness. 8.Hello friends, from today we are going to start back to back CNC programming, so friends, we need CNC programming, first AutoCAD drawing, then first we made .In this series of videos I walk through the full process of designing and cutting a part to be cut on a CNC router. In part one I do the basic CAD design wo.

CNC machining drawings are the blueprints for precisely manufactured operations that ensure the accuracy and efficiency at the core of the process. These intricate drawings determine the dimensions, shape, and tolerances required by CNC machines to manufacture virtually perfect products in high volume. In this article, we’ll focus on getting your CAD file ready for CNC machining. In CNC machining, numerical control technology manages the machine’s work, whereby a software program is pre-made to control an object.Learn how to convert CAD to CAM (Computer Aided Design to Computer Aided machining). You can supply good clean DWG or DXF geometry to your CNC programmer.

Dassault Systèmes 3D ContentCentral is a free library of thousands of high quality 3D CAD models from hundreds of suppliers. Millions of users download 3D and 2D CAD files everyday. CNC Vertical Machining CenterHow do you prepare technical drawings for CNC machining and why are they important? Technical drawings are widely used in manufacturing to improve the communication of technical requirements between the designer and engineer and the manufacturer.Connect disciplines using common CAD models to program CNC machines. Design fixtures and create toolpaths before engineering data is released—any changes automatically update computer-aided manufacturing (CAM) workflows.

On this episode of Make It Kustom, I walk you through drawing a part in AutoCAD to CNC plasma cutting the part. This is meant to be a introduction to the pro. Therefore, this article is dedicated to helping you learn how to prepare CAD files for CNC machining. 1. Optimize Tolerances. 2. Type of Material. 3. Minimize the Number of Machined Features. 4. Minimize Machined Stock Allowance. 5. Standardize Features. 6. Surface Finish. 7. Provide Adequate Strength and Stiffness. 8.Hello friends, from today we are going to start back to back CNC programming, so friends, we need CNC programming, first AutoCAD drawing, then first we made .In this series of videos I walk through the full process of designing and cutting a part to be cut on a CNC router. In part one I do the basic CAD design wo.

free cad software for cnc

CNC machining drawings are the blueprints for precisely manufactured operations that ensure the accuracy and efficiency at the core of the process. These intricate drawings determine the dimensions, shape, and tolerances required by CNC machines to manufacture virtually perfect products in high volume. In this article, we’ll focus on getting your CAD file ready for CNC machining. In CNC machining, numerical control technology manages the machine’s work, whereby a software program is pre-made to control an object.Learn how to convert CAD to CAM (Computer Aided Design to Computer Aided machining). You can supply good clean DWG or DXF geometry to your CNC programmer.Dassault Systèmes 3D ContentCentral is a free library of thousands of high quality 3D CAD models from hundreds of suppliers. Millions of users download 3D and 2D CAD files everyday. CNC Vertical Machining Center

How do you prepare technical drawings for CNC machining and why are they important? Technical drawings are widely used in manufacturing to improve the communication of technical requirements between the designer and engineer and the manufacturer.

grid sheet metal

free cad cam cnc

To bring it all together, being unable to manufacture a good part in CNC machining is often a consequence of overlooked details, neglected maintenance, or improper handling.

cnc machine autocad drawing|auto cad cnc drawing