cnc machine for cutting metal Laguna utilizes cutting-edge CNC and motion control systems for a wide range of applications - from basic high-volume, high-repetition commodity production, to unique, highly complex parts . How to Find the Septic D_box - Distribution Box. See SEPTIC D-BOX INSTALL, LOCATE, REPAIR where we describe how to find the drop box, D-box or distribution box and how to inspect and repair it depending on what you see there. How to Find the Septic Drainfields or Leaching Beds or Soakaway Pits

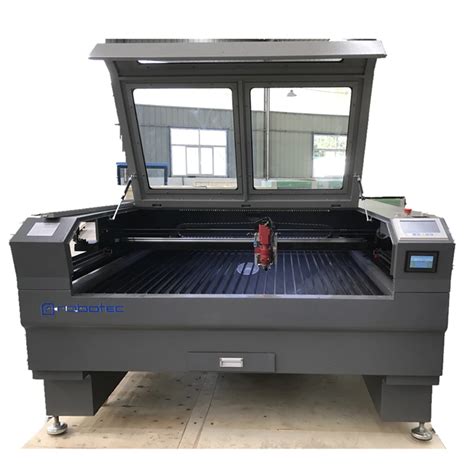

0 · industrial metal laser cutting machine

1 · hobby cnc machine for metal

2 · cnc metal cutting machine price

3 · cnc automatic cutting metal machine

4 · best metal cutting cnc machine

5 · best desktop cnc for metal

6 · best cnc router for metal

7 · affordable cnc machines for metal

We’ve looked at the box spring while someone is laying on it and can see that it bends/flexes a decent amount under our weight. Neither of us are especially heavy (I’m the heaviest between us at 165 lbs). Can anyone recommend a bed frame that has really strong and even support that won’t break the bank?

Laguna utilizes cutting-edge CNC and motion control systems for a wide range of applications - from basic high-volume, high-repetition commodity production, to unique, highly complex parts .While our Shapeoko CNC Router and Shapeoko HDM have a large cutting area with a lot of power, the Nomad is built to take up minimal space and cut a wide variety of materials without .CNC Machine 4040-PRO MAX with 710W Trimmer CNC Router & Linear Rail Driven, 3 Axis Engraving Machine for Wood Metal Acrylic Cutting Milling, GRBL Control, Work Area 400 x .

,399.009.00

9.009.009.00

9.99 Cutting metal on a CNC machine can be challenging, but using an appropriate CNC, selecting the right cutting tool, working with machinable metals, and setting the optimal parameters will help you overcome these challenges . The best metal CNC machines for aluminum, steel, titanium & more: Taig 2019CNC Micro Mill — Cheapest CNC mill for tougher metals; MillRight CNC Power Route XL — Large metal machine with high torque; Tormach PCNC 440 CNC Mill — Powerful desktop option; Laguna Swift 4×8 CNC Router — The premium industrial choice

Laguna utilizes cutting-edge CNC and motion control systems for a wide range of applications - from basic high-volume, high-repetition commodity production, to unique, highly complex parts that require the highest precision and advanced machining techniques.While our Shapeoko CNC Router and Shapeoko HDM have a large cutting area with a lot of power, the Nomad is built to take up minimal space and cut a wide variety of materials without making a mess. The Nomad 883 Pro includes all the hardware and software you need to take your 3D file and make a part. CNC cutting machines cover a broad spectrum of metal shapes, sizes, types, and operations, yet they have several characteristics that connect them under the standard banner of CNC machines. Here are eight of those traits: 1. Metal CNC Machines Perform Various Metal Cutting Operations Flawlessly.

CNC Machine 4040-PRO MAX with 710W Trimmer CNC Router & Linear Rail Driven, 3 Axis Engraving Machine for Wood Metal Acrylic Cutting Milling, GRBL Control, Work Area 400 x 400 x 78mm Cutting metal on a CNC machine can be challenging, but using an appropriate CNC, selecting the right cutting tool, working with machinable metals, and setting the optimal parameters will help you overcome these challenges and produce clean cuts in metals.

CNC metal cutting machines are advanced tools that use computer programming to control the movement and operation of cutting tools. They are specifically designed for precision metal cutting and offer a highly efficient and accurate method for shaping various types of metals. There are several types of CNC machines designed specifically for metalworking applications. Some common types include: CNC Milling Machines: These machines use rotary cutters to remove material from a workpiece, creating complex shapes and contours.Laguna CNC waterjet cutters offer high-performance cutting in thicker metal and heat-sensitive products without sacrificing edge quality. With our user-friendly machine interface, sturdy one-piece frame, in-person machine/software training, and customized table sizes, Laguna Tools makes CNCs easy to use. Want More Info? More and more metalworking companies choose CNC metal cutting machines due to their high automation, excellent precision, and high efficiency. This article introduces the four most common CNC metal cutting machines, namely laser cutting, plasma cutting, water-jet cutting, and flame cutting.

The best metal CNC machines for aluminum, steel, titanium & more: Taig 2019CNC Micro Mill — Cheapest CNC mill for tougher metals; MillRight CNC Power Route XL — Large metal machine with high torque; Tormach PCNC 440 CNC Mill — Powerful desktop option; Laguna Swift 4×8 CNC Router — The premium industrial choiceLaguna utilizes cutting-edge CNC and motion control systems for a wide range of applications - from basic high-volume, high-repetition commodity production, to unique, highly complex parts that require the highest precision and advanced machining techniques.While our Shapeoko CNC Router and Shapeoko HDM have a large cutting area with a lot of power, the Nomad is built to take up minimal space and cut a wide variety of materials without making a mess. The Nomad 883 Pro includes all the hardware and software you need to take your 3D file and make a part.

CNC cutting machines cover a broad spectrum of metal shapes, sizes, types, and operations, yet they have several characteristics that connect them under the standard banner of CNC machines. Here are eight of those traits: 1. Metal CNC Machines Perform Various Metal Cutting Operations Flawlessly.CNC Machine 4040-PRO MAX with 710W Trimmer CNC Router & Linear Rail Driven, 3 Axis Engraving Machine for Wood Metal Acrylic Cutting Milling, GRBL Control, Work Area 400 x 400 x 78mm Cutting metal on a CNC machine can be challenging, but using an appropriate CNC, selecting the right cutting tool, working with machinable metals, and setting the optimal parameters will help you overcome these challenges and produce clean cuts in metals.

CNC metal cutting machines are advanced tools that use computer programming to control the movement and operation of cutting tools. They are specifically designed for precision metal cutting and offer a highly efficient and accurate method for shaping various types of metals. There are several types of CNC machines designed specifically for metalworking applications. Some common types include: CNC Milling Machines: These machines use rotary cutters to remove material from a workpiece, creating complex shapes and contours.

Laguna CNC waterjet cutters offer high-performance cutting in thicker metal and heat-sensitive products without sacrificing edge quality. With our user-friendly machine interface, sturdy one-piece frame, in-person machine/software training, and customized table sizes, Laguna Tools makes CNCs easy to use. Want More Info?

industrial metal laser cutting machine

hobby cnc machine for metal

cnc metal cutting machine price

Wide l bracket only need to be screwed on. Round ends and countersunk allow l bracket to be flat after screw are installed, with no protrusions to cause scratches. Widely used in repairing and strengthening chair, bed, table, cabinet and other wood furniture.

cnc machine for cutting metal|best desktop cnc for metal