inventor sheet metal bend on part of surface sheet metal bend. Hello, I need some advice please on how best to create a . $326.12

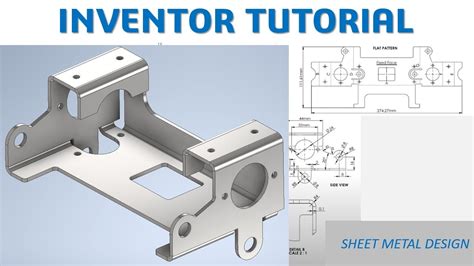

0 · sheet metal inventor tutorial pdf

1 · sheet metal inventor tutorial

2 · inventor unfold sheet metal

3 · inventor sheet metal exercises pdf

4 · inventor fold sheet metal

5 · inventor change sheet metal thickness

6 · autodesk inventor sheet metal tutorial

7 · autodesk inventor bending plate

Generally, if you have a large capacity FCU that requires its return air to be ducted, you’ll need to use a plenum box. Otherwise, you can use the space above the ceiling as a plenum. Such a method is called free return as opposed to ducted return.

A single flange or contour flange feature in a sheet metal part can contain any number of bends. You can override default sheet metal styles from the Bend dialog box as you create your sheet metal bend. These settings include how the flat pattern unfolds, and the bend relief settings .The problem is that Inventor Sheet metal can't bend non-straight sheets. Here's a .sheet metal bend. Hello, I need some advice please on how best to create a .A bend note adds fabricating information to sheet metal bend centerlines. Bend .

The main rule to flat a part is. you must ensure all the part has the same thickness all over. You doesnt have the same thickness all over the part. My advice: Second: for this case, build the first extrude based in one profile .

The problem is that Inventor Sheet metal can't bend non-straight sheets. Here's a quick attempt to create the shape you're after (also see attached IPT (Inventor 2023.2), but as you can see there will be a "rip" in the sheet.

sheet metal bend. Hello, I need some advice please on how best to create a Bend in the attached INV2015 part. I have a sketch line where i need to Bend the Tabs. 1. How do i . Autodesk Inventor Sheet Metal Face command with Bend option. Inventor Luke. 1.66K subscribers. Subscribed. 78. 11K views 4 years ago.

Sketch on the surface that will have the bend attached, and draw two lines. Use the split tool to split the surface accordingly. Use the Delete Face tool to remove the faces of the solid body which will join the bent part.To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the Sheet Metal Defaults dialog appears. This dialog displays the default preferences of the sheet metal .A bend note adds fabricating information to sheet metal bend centerlines. Bend notes are associated with a drawing view. A bend table lists propertied of all bends in a flat pattern view of a sheet metal part.

The Shape tab lets you specify the sheet metal faces and the bend settings to use when joining two or more faces. Faces are automatically trimmed or extended to create the bend. Single . Bending Flat Plate in Sheet Metal. I am trying to make a part that is an arced piece of sheet metal with holes on the edges and down the middle (see picture attached), and I want to make it as a sheet metal part so I can get the . Mirror the Surface Body to create a symmetrical copy of it. Sketch on the surface that will have the bend attached, and draw two lines. Use the split tool to split the surface accordingly. Use the Delete Face tool to remove the . How to calculate K-Factor in Inventor for Sheet Metal part? What is Bend Allowance? More material is stretch when is compresses, which lead in part being longer after bending How to calculate K-Factor for Inventor Sheet .

I have problem to create Flat Pattern od this part (in attachment). I make this part as standard part with sweep along the curve and than convert to Sheet metal, but there is problem, because Flat Pattern is not right. Anyone . Hi. I am messing around with a part at the moment so if I was to put it up as an .ipt file it would be crucified for not being constrained, dimensioned etc etc. I am stumped I have to say. I am trying to get a 25 and 20mm return fold on the back of a curved panel. No matter what I have tried I cannot figure out how to do this, I manged to get the model bend on it however this .

In this video Pete demonstrates a technique for creating a secondary sheet metal component that follows the contour of another plate part. He'll also share a.

I need to create a bend in sheet metal that in a model could be done as a coil but I need to create the bend so it will lay flat in sheet metal. The bend is done daily in our factory. The bend at 1 end it 40deg and changes to 70 deg at the other end. Total length of the segment is 150-200 inches depending on the product we are making. Is there a way to use .

- use 'cut across bend' to remove sections - construct a surface and thicken it - do some flat pattern clean up work in the unfolded state (model in flat pattern) . I have a substantial folder of sheet metal parts that could not possibly be made with just the sheet metal tools. The key is uniform thickness and perpendicular cut edges in the . Learn how to use Autodesk Inventor's Sheet Metal Face command with Bend option in this tutorial video.

metal carport connected to house

Your part has a curve, which the flange follows. Inventor sheet metal does not support that. In other words, your part may need to be a die formed part, not a press brake formed part. However, you can model any type of part in Inventor, but to get a proper flat pattern out means no non-linear deformation in sheet metal mode. Hope this helps.'If we are not in a sheetmetal part, then don't continue. Dim doc As Inventor.Document = ThisApplication.ActiveDocument. If doc.SubType <> "{9C464203-9BAE-11D3-8BAD-0060B0CE6BB4}" `MessageBox.Show("Document is not a sheet metal part.")` `Return` End If 'Must convert Inventor.Document to Inventor.PartDocument interface so we can access .

1. Connecting Multiple Sheet Metal Bodies (Bend Command) Often, sheet metal is brought into the picture after a multi-body assembly is created. Now, you as a designer are in charge of using Sheet Metal to connect these bodies together. First, you could start by performing a combination of projecting bodies and creating new sketches in your design.There's no geometry for inventor to pick up for a contour flange. I just tried to do it with a contour flange. Reply reply . Use extrusion and check bend rule in Sheet metal default before you bend the part. Bend rules need to match with thickness. Reply reply . Surface Flattening a stamped metal part?About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . IV10 SP2 Is there an easy way to get the Flat pattern area into the parts list through one of the parameters. Do I have to create a parameter and calculate that using the Bend allownance or is it straight forward. - The Area shown in the iProperties-Physical-General Properties. Is this area the total area on both sides of the sheet metal part.

Hi I have a metal part in which i need a bend on the edge. I have attached my attempt but are there other ways to make this shape Part attached is 2019 Cheers JS . Welcome to Autodesk’s Inventor Forums. Share your knowledge, ask questions, and explore popular Inventor topics. . you will need to use Unwrap in 2020. Sheet metal flat pattern . When bending sheet metal, Inventor states the flange as being bent up when inserting bend notes on drawings but the bend line is actually bent down as would be the case on the press brake as the knife presses into the vee. . orient your first bend in producing the part to "bend up". As long as your consistent, it shouldn't make a difference . I have attached a picture of the finished part in this post. It is made from 16 gauge sheet metal that is cut to shape, curved to a radius of ~4.4 then has the tabs on the side bent down at a 90 degree angle. I cannot figure out how to model the complex shape in a curve or how to curve the complex shape at a 4.4 radius. ; Thanks for looking.

Some time ago a colleague made a 2D-drawing of a sheet metal part with 2 bends in it. Somehow Inventor has swapped bend marks in the flat pattern, and as a result the part is bend the wrong way. How is it possible that Inventor has swapped bend marks and how could we prevent this to happen in the fu.

sheet metal inventor tutorial pdf

Can you use a smaller radius curve? Usually in sheet metal bend radius is ignored in sharp 90 degree bends. Bends with a radius larger than the material thickness tend to be where it becomes an issue (Aluminum sheet, for example, often cracks when small radius bends are used, so the radius is often a few times the material thickness).convert Sheet Metal from a standard part to exact and extract a Sheet Metal plate from existing solids. So with all these feature tools that you get the chance to make a multiple in Inventor Sheet Metal. So flat pattern is another important area we need to mention in this section. So there are four main tools in Inventor to create a Sheet Metal .Inventor has punch tools too. But what you need to figure out is how you're gonna make it first. If you create a sketch on a flat surface, then draw the shape you want, then add a offset for the relief cuts. Hard to explain w/out images sorry. Then after this sketch is ready, use the cut tool to remove the relief cut. Then right click share sketch.

metal carport ideas for front of house

You can bend your original model using the sheet metal fold command. You just have to set your sheet metal thickness to the thickness of the channel web first. As long as the thickness of the part is uniform through the bend line and matches the sheet metal thickness then you can bend it. This way you could get a flat pattern using one file.

use the bend tool with a large bend radius?--Kent Assistant Moderator Autodesk Discussion Forum Moderator Program "Gary_M" wrote in message news .A crucial part of it is the beams (mockup in pic.2) . I have a lot of experience with sheet metal in Inventor (it's what I do for a living). If you want to send me a link to download the files, I'll have a look. . that's adaptive to the baseplate (triangle). Since you're "beam" is not orthogonal to the surface of the base plate, the bend .

You can do this using the "Bend Part" tool. It is on the extended Modify panel. After you do the Bend part, convert it to sheet metal and enter the correct thickness. It should flatten then. If you still have problems, post your file and someone will help.

Inventor will calculate bend allowance. Model your sheet metal part in finished as-bent dimensions and then attach the file here for suggestions. The bend allowance is dependent of material, thickness, inside bend radius and bend angle (with . Okay, I managed to add some bends to my sheet metal part. In fact, too many bends, (joining adjacent right angle sides) so I can't flatten it. How can I remove a bend that is down in the stack (like one can in Max)? Is this possible? Picking the bend in the browser doesn't seem to yield any "delete" options, no matter how I may click, left or right.

metal buzz lightyear lunch box

metal cabin house plans

metal carport attached to side of house

$12K+

inventor sheet metal bend on part of surface|inventor change sheet metal thickness