cnc 5 axis machining aluminum DDPROTOTYPE is a complete 5-axis CNC machining workshop, which can custom aluminum machining prototype according to customer requirements. We accept the most common CAD file formats, including: step, IGS, x_T and .PDF files. Deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius.

0 · what is 5 axis milling

1 · what does 5 axis mean

2 · small 5 axis cnc mill

3 · benefits of 5 axis machining

4 · 5 axis trunnion machining

5 · 5 axis machining explained

6 · 5 axis machining basics

7 · 5 axis cnc explained

If your project needs electrical boxes or enclosures, and you don’t know what are the main types of electrical enclosures, you need to read this guide, I will tell you 76 types of electrical boxes for your business based on material, .

what is 5 axis milling

DDPROTOTYPE is a complete 5-axis CNC machining workshop, which can custom aluminum machining prototype according to customer requirements. We accept the most common CAD file formats, including: step, IGS, x_T and .PDF .Trace-A-Matic conquers complex part manufacturing with state-of-the-art 5-axis CNC machining, backed by decades of experience and unmatched creativity. The 5-axis platform cuts part geometry and machines complex shapes unachievable by other machining methods due to additional axes and the exceptional mobility of workpiece to tool rotational axes.DDPROTOTYPE is a complete 5-axis CNC machining workshop, which can custom aluminum machining prototype according to customer requirements. We accept the most common CAD file formats, including: step, IGS, x_T and .PDF files.

Our engineers and machinists can perform true 5 axis machining services work and produce five axis machining aluminum parts with ease. No matter how complex aluminum CNC machining parts, each step will be executed with a rigorous attitude, to deliver exceptional 5 axis machining components that demonstrate the highest quality standards.

Experience exceptional precision and performance with our advanced CNC 5-axis machining services. Our Capabilities: The ability to provide 3+2 or simultaneous 5-axis milling allows us to deliver high quality and high complexity precision machining.

At Xc machining we have a wide range of CNC aluminum machining including 3, 4, and 5-axis machines on standby to process your order, thus guaranteeing a fast lead time. Our production capabilities ranges from making aluminum prototypes to small- . 5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, accuracy, speed, and production efficiency.At Ultirapid, we offer cutting-edge 5-axis CNC machining services using advanced Mikron and Mazak machines to deliver precision and efficiency. Our commitment to quality is upheld through our ISO9001 certification, ensuring that every part meets the highest standards.

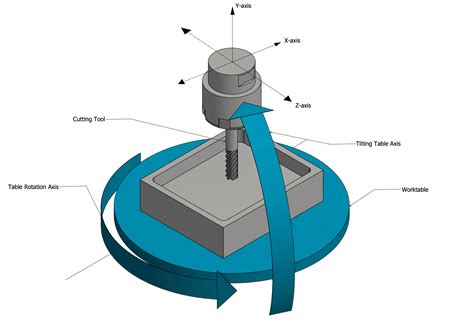

The 5-axis linkage of aluminum alloy means that there are at least 5 coordinate axes (that is, three linear coordinates and two rotary coordinates) on a machine tool, and can be simultaneously coordinated to process aluminum under the control of a .

5 axis CNC machining aluminum is a process that uses computer numerical control (CNC) technology to machine aluminum parts. The aluminum material is first mounted on the CNC cutting machine and then the machine moves the cutting tool in various directions to create the desired shape. Compared with traditional four-axis machining, five-axis machining can control the tool in multiple directions, so that the dimensional accuracy and shape and position tolerance of the processing part can be better guaranteed, especially in the processing of complex parts.

Trace-A-Matic conquers complex part manufacturing with state-of-the-art 5-axis CNC machining, backed by decades of experience and unmatched creativity. The 5-axis platform cuts part geometry and machines complex shapes unachievable by other machining methods due to additional axes and the exceptional mobility of workpiece to tool rotational axes.DDPROTOTYPE is a complete 5-axis CNC machining workshop, which can custom aluminum machining prototype according to customer requirements. We accept the most common CAD file formats, including: step, IGS, x_T and .PDF files.Our engineers and machinists can perform true 5 axis machining services work and produce five axis machining aluminum parts with ease. No matter how complex aluminum CNC machining parts, each step will be executed with a rigorous attitude, to deliver exceptional 5 axis machining components that demonstrate the highest quality standards.Experience exceptional precision and performance with our advanced CNC 5-axis machining services. Our Capabilities: The ability to provide 3+2 or simultaneous 5-axis milling allows us to deliver high quality and high complexity precision machining.

At Xc machining we have a wide range of CNC aluminum machining including 3, 4, and 5-axis machines on standby to process your order, thus guaranteeing a fast lead time. Our production capabilities ranges from making aluminum prototypes to small- . 5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, accuracy, speed, and production efficiency.

what does 5 axis mean

At Ultirapid, we offer cutting-edge 5-axis CNC machining services using advanced Mikron and Mazak machines to deliver precision and efficiency. Our commitment to quality is upheld through our ISO9001 certification, ensuring that every part meets the highest standards.The 5-axis linkage of aluminum alloy means that there are at least 5 coordinate axes (that is, three linear coordinates and two rotary coordinates) on a machine tool, and can be simultaneously coordinated to process aluminum under the control of a . 5 axis CNC machining aluminum is a process that uses computer numerical control (CNC) technology to machine aluminum parts. The aluminum material is first mounted on the CNC cutting machine and then the machine moves the cutting tool in various directions to create the desired shape.

A Switch boxes is a rectangular shape metal/PVC box which is used to receive light wires, power wires & on which switches can be mounted. It is used as a junction box also. Various types of switches are used such as MS, Zinc-chromate plated metal box & PVC box.

cnc 5 axis machining aluminum|benefits of 5 axis machining