ai applications in sheet metal forming The first chapter offers an introduction to various AI techniques and sheet metal forming, while subsequent chapters describe traditional procedures/methods used in various . In this blog, you will explore the key differences between these methods and their practical applications, helping you choose the most suitable contract manufacturer for your specific metal part needs. Types of Metal .

0 · sheet metal forming process

1 · sheet metal forming ai

2 · metal forming artificial intelligence

3 · metal forming ai

4 · artificial intelligence in metal sheeting

5 · artificial intelligence forming process

The four most common types of sheet metal hems used by Approved Sheet Metal are closed hem, teardrop hem, open hem, and rolled hem.

Demonstrates applications of various AI techniques in sheet metal forming, using real industrial sheet metal parts; Includes flow charts explaining the execution of the systems developed using AI techniquesDesign of sheet metal forming dies, however, is complex and largely . In manufacturing, AI has been applied to improve processes, reduce costs, and increase reliability. A novel manufacturing process that has been augmented with AI is . The first chapter offers an introduction to various AI techniques and sheet metal forming, while subsequent chapters describe traditional procedures/methods used in various .

AI algorithms used to analyze data from metal forming processes and identify opportunities for improvement will be reviewed. It is also possible to ‘invert’ process models by . AI methods are popular for most engineering applications, including sheet metal forming. In that regard, they can be applied to both process optimization and constitutive .

Summary: This book comprises chapters on research work done around the globe in the area of artificial intelligence (AI) applications in sheet metal forming. The first chapter offers an . Design of sheet metal forming dies, however, is complex and largely experience-based. This chapter presents an overview of applying artificial intelligence (AI) tools and .The first chapter offers an introduction to various AI techniques and sheet metal forming, while subsequent chapters describe traditional procedures/methods used in various sheet metal .Demonstrates applications of various AI techniques in sheet metal forming, using real industrial sheet metal parts; Includes flow charts explaining the execution of the systems developed using AI techniques

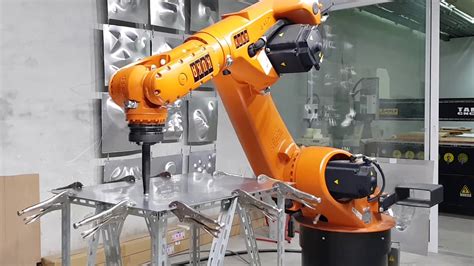

In manufacturing, AI has been applied to improve processes, reduce costs, and increase reliability. A novel manufacturing process that has been augmented with AI is Incremental Sheet Forming (ISF), a technology that applies a step-by-step incremental feed to a sheet metal or polymer blank using a CNC machine. The first chapter offers an introduction to various AI techniques and sheet metal forming, while subsequent chapters describe traditional procedures/methods used in various sheet metal. AI algorithms used to analyze data from metal forming processes and identify opportunities for improvement will be reviewed. It is also possible to ‘invert’ process models by training algorithms that map from output to input, which allows for fast process optimization. AI methods are popular for most engineering applications, including sheet metal forming. In that regard, they can be applied to both process optimization and constitutive modeling. The first example we’ll look at is hairpin forming, an essential part for electric motors achieved using three bending processes: R-bending, V-bending, and U-bending.

Summary: This book comprises chapters on research work done around the globe in the area of artificial intelligence (AI) applications in sheet metal forming. The first chapter offers an introduction to various AI techniques and sheet metal forming, while subsequent chapters describe traditional procedures/methods used in various sheet metal .

sheet metal forming process

sheet metal forming ai

Design of sheet metal forming dies, however, is complex and largely experience-based. This chapter presents an overview of applying artificial intelligence (AI) tools and techniques in designing and planning of sheet metal progressive dies.The first chapter offers an introduction to various AI techniques and sheet metal forming, while subsequent chapters describe traditional procedures/methods used in various sheet metal forming processes, and focus on the automation of those processes by means of AI techniques, such as KBS, ANN, GA, CBR, etc. Feature recognition and the .

It is found that AI techniques such as artificial neural networks, support vector regression, decision trees, fuzzy logic, genetic algorithms, particle swarm optimization have been used in solving IF-relevant problems. In addition, hybrid methods that combine some of the above-mentioned techniques have also been used.

A novel manufacturing process that has been augmented with AI is Incremental Sheet Forming (ISF), a technology that applies a step-by-step incremental feed to a sheet metal or polymer blank.Demonstrates applications of various AI techniques in sheet metal forming, using real industrial sheet metal parts; Includes flow charts explaining the execution of the systems developed using AI techniques In manufacturing, AI has been applied to improve processes, reduce costs, and increase reliability. A novel manufacturing process that has been augmented with AI is Incremental Sheet Forming (ISF), a technology that applies a step-by-step incremental feed to a sheet metal or polymer blank using a CNC machine.

The first chapter offers an introduction to various AI techniques and sheet metal forming, while subsequent chapters describe traditional procedures/methods used in various sheet metal. AI algorithms used to analyze data from metal forming processes and identify opportunities for improvement will be reviewed. It is also possible to ‘invert’ process models by training algorithms that map from output to input, which allows for fast process optimization. AI methods are popular for most engineering applications, including sheet metal forming. In that regard, they can be applied to both process optimization and constitutive modeling. The first example we’ll look at is hairpin forming, an essential part for electric motors achieved using three bending processes: R-bending, V-bending, and U-bending.

Summary: This book comprises chapters on research work done around the globe in the area of artificial intelligence (AI) applications in sheet metal forming. The first chapter offers an introduction to various AI techniques and sheet metal forming, while subsequent chapters describe traditional procedures/methods used in various sheet metal . Design of sheet metal forming dies, however, is complex and largely experience-based. This chapter presents an overview of applying artificial intelligence (AI) tools and techniques in designing and planning of sheet metal progressive dies.The first chapter offers an introduction to various AI techniques and sheet metal forming, while subsequent chapters describe traditional procedures/methods used in various sheet metal forming processes, and focus on the automation of those processes by means of AI techniques, such as KBS, ANN, GA, CBR, etc. Feature recognition and the .

It is found that AI techniques such as artificial neural networks, support vector regression, decision trees, fuzzy logic, genetic algorithms, particle swarm optimization have been used in solving IF-relevant problems. In addition, hybrid methods that combine some of the above-mentioned techniques have also been used.

metal forming artificial intelligence

double gang outdoor junction box

This guide reviews the types of metal roofing (plus their pros, cons, and costs) to help you decide which option is best for your home, so continue reading to learn more. Find a local contractor to get started with metal roof installation today.

ai applications in sheet metal forming|artificial intelligence forming process