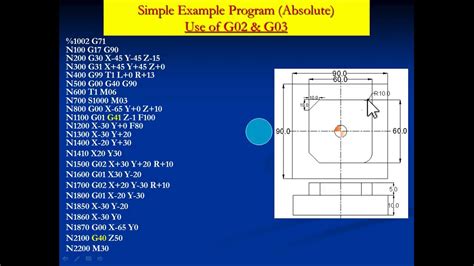

circular interpolation program for cnc machine G02 instructs the CNC machine to move along a Circular Arc from its current position to a new coordinate. The movement is performed with a controlled federate. The new coordinate can be absolute or relative, depending on the . Heat loss in houses is mostly through movement of air through the house (draughts) and conduction through the walls, not direct radiation through the windows. Shutters in winter .

0 · g02 g03 milling programming example

1 · g02 g03 lathe programming example

2 · cnc ijk explained

3 · cnc circular interpolation examples

4 · circular interpolation milling program

5 · circular interpolation g code example

6 · circular interpolation calculator

7 · calculate ijk in cnc programming

Anywhere you have wires spliced together, you need a junction box. Building codes require this protection because contact between wires can cause a spark. That's dangerous.

G02 instructs the CNC machine to move along a Circular Arc from its current position to a new coordinate. The movement is performed with a controlled federate. The new coordinate can be absolute or relative, depending on the .Helical (spiral) motion is possible with G02 or G03 by programming the linear axis that is not in the selected plane. This third axis will be moved along the specified axis in a linear manner, while . Master the art of circular interpolation with our guide on G02 and G03 CNC codes. Learn to program arcs in CNC milling through detailed examples and techniques. Circular interpolation is quite a bit more demanding on your machine as two axes have to be precisely coordinated. Drawing a complete gcode circle involves not just .

G02 sets the CNC movement mode to clockwise circular movement, otherwise known as circular interpolation. G02 is used to move the CNC around along a specified radius set with the R code in a clockwise .This is a series of articles for cnc machinists/programmers to explain the Concepts and Programming methods of Circular Interpolation. What is a circular interpolation: a translation of linear axis positions into curved tool motions is .

2nd part of Circular Interpolation Concepts & Programming series, this article explains the required information to program/machine circular interpolation on a cnc machine, and how cnc machinists can program circular. G03 sets the CNC movement mode to counterclockwise circular movement, otherwise known as circular interpolation. G03 is used to move the CNC around along a specified radius set with the R code in a .

g02 g03 milling programming example

Circular interpolation using G03 allows for precise machining of arcs by specifying them counterclockwise relative to initial point XY. This means you must give endpoint coordinates X and Y alongside centre point (I,J) where .A guide to basic G code programming techniques for the home cnc hobbyist, focusing on circular interpolation.G02 instructs the CNC machine to move along a Circular Arc from its current position to a new coordinate. The movement is performed with a controlled federate. The new coordinate can be absolute or relative, depending on the effective mode . .

Helical (spiral) motion is possible with G02 or G03 by programming the linear axis that is not in the selected plane. This third axis will be moved along the specified axis in a linear manner, while the other two axes will be moved in the circular motion.

Master the art of circular interpolation with our guide on G02 and G03 CNC codes. Learn to program arcs in CNC milling through detailed examples and techniques. Circular interpolation is quite a bit more demanding on your machine as two axes have to be precisely coordinated. Drawing a complete gcode circle involves not just coordinated motion but reversal of direction at each of the 4 quadrant points. G02 sets the CNC movement mode to clockwise circular movement, otherwise known as circular interpolation. G02 is used to move the CNC around along a specified radius set with the R code in a clockwise direction and at a feed rate set with the F code.This is a series of articles for cnc machinists/programmers to explain the Concepts and Programming methods of Circular Interpolation. What is a circular interpolation: a translation of linear axis positions into curved tool motions is called circular interpolation.

2nd part of Circular Interpolation Concepts & Programming series, this article explains the required information to program/machine circular interpolation on a cnc machine, and how cnc machinists can program circular. G03 sets the CNC movement mode to counterclockwise circular movement, otherwise known as circular interpolation. G03 is used to move the CNC around along a specified radius set with the R code in a counterclockwise direction and at a feed rate set with the F code. Circular interpolation using G03 allows for precise machining of arcs by specifying them counterclockwise relative to initial point XY. This means you must give endpoint coordinates X and Y alongside centre point (I,J) where these two meet up with each other.

A guide to basic G code programming techniques for the home cnc hobbyist, focusing on circular interpolation.G02 instructs the CNC machine to move along a Circular Arc from its current position to a new coordinate. The movement is performed with a controlled federate. The new coordinate can be absolute or relative, depending on the effective mode . .Helical (spiral) motion is possible with G02 or G03 by programming the linear axis that is not in the selected plane. This third axis will be moved along the specified axis in a linear manner, while the other two axes will be moved in the circular motion.

Master the art of circular interpolation with our guide on G02 and G03 CNC codes. Learn to program arcs in CNC milling through detailed examples and techniques.

Circular interpolation is quite a bit more demanding on your machine as two axes have to be precisely coordinated. Drawing a complete gcode circle involves not just coordinated motion but reversal of direction at each of the 4 quadrant points.

G02 sets the CNC movement mode to clockwise circular movement, otherwise known as circular interpolation. G02 is used to move the CNC around along a specified radius set with the R code in a clockwise direction and at a feed rate set with the F code.This is a series of articles for cnc machinists/programmers to explain the Concepts and Programming methods of Circular Interpolation. What is a circular interpolation: a translation of linear axis positions into curved tool motions is called circular interpolation.2nd part of Circular Interpolation Concepts & Programming series, this article explains the required information to program/machine circular interpolation on a cnc machine, and how cnc machinists can program circular.

G03 sets the CNC movement mode to counterclockwise circular movement, otherwise known as circular interpolation. G03 is used to move the CNC around along a specified radius set with the R code in a counterclockwise direction and at a feed rate set with the F code.

g02 g03 lathe programming example

cnc automatic router machine

cnc ijk explained

Located in Wichita Falls, TX, with over 200,000 sq ft and 100+ professionals offering turn-key solutions to our customers, enabling them to focus on their core business. Sheet metal fabrication, precision machining, complex machined weldments, heavy fabrication projects, assembly and project management make up our core operational competencies.

circular interpolation program for cnc machine|calculate ijk in cnc programming