how to make cnc parts In this tutorial I will show you how I built the simplest CNC machine with minimum parts possible and without using a 3D printer. Sheet metal workers who are members of Local 312 enjoy one of the most extensive benefit packages of any industry. These benefits include vision, dental, and healthcare insurance .

0 · make your own cnc router

1 · machine to make your own

2 · homemade cnc router parts

3 · homemade cnc parts

4 · cnc mill parts diagram

5 · cnc machine spare parts list

6 · cnc machine parts list pdf

7 · build your own cnc kit

$25.00

make your own cnc router

The latest cnc machines are controlled via gcode and grbl, repetier, or Marlin based controllers. Using mach 4 is a bit like using Windows to set up . In this tutorial I will show you how I built the simplest CNC machine with minimum parts possible and without using a 3D printer.

metal junction box wire clamp

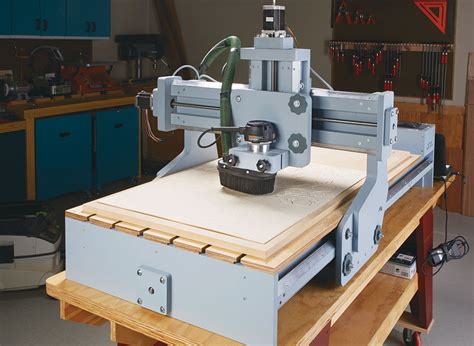

This instructable shows all the steps I went through in designing and building this CNC router. The main thing I like about a CNC router, is that it is so versatile. .Make Your Own DIY CNC: This instructable outlines the assembly process of my 2nd generation CNC machine which I designed to be simple to build and quiet enough to be apartment friendly. I have included example projects that I have . DIY CNC Router/Machine: How to Build Your Own. by Andreas Giencke. Updated Feb 6, 2023. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to .

Designing Your DIY CNC Machine:\. Building a CNC machine requires careful planning and design. In this section, we will discuss the essential components you'll need, such as stepper .Proto-mold can help you make a beautiful parts!Please choose and trust us.#cnc #cncpartsfactory #cncmachineparts #precisionmold #prototype #metalpart #cncpar.

Cnc machinist here, some complicated parts that need things like a 6 axis cnc can take up to 10 hours of programming and setup time, not to mention harder materials like ss require more expensive tools or the machine has to be run . This post discusses the importance of accuracy and precision in CNC milling and some tips to improve precision and accuracy in CNC milling. [email protected]. 866.262.6233 REQUEST A QUOTE. HOME; CAPABILITIES. . To produce the highest quality parts and products, all aspects of the machining process must be done with high accuracy. . If you imagine what a detail should be, we are imagining how to do it.Professionally, efficiently and quickly execute your part.Contact us: https://bnkmachin.

Do it yourself CNC machines can be never ending projects. Once you get one machine done, you want another. [Mario] found this out when he started work on his second CNC machine, TheMaker2. As its n. for each one of these sheets individually and then just export those toolpaths and you'll be ready to go. That's all for this video. Make sure you like and subscribe for more. And if you want to master your vectric software, make sure you check out my vectric training classes linked right hereThe circuit diagram used in this project is shown here, start by connecting the motor drivers to the CNC shield. Followed by connecting the enabling pins together, Now connect the stepper motors to the CNC shield, The laser diode has to be connected to the power supply via IRFZ44N Mosfet and a couple of resistors. Bipolar stepper motor controller_Home Madehttps://youtu.be/OsMilSlpCkwprinter shape rodprinter timing beltprinter head timing pulley printer head socket 1/2 .

At times, some of these parts will have reasonably tight tolerances for parallelism and/or flatness, for example +/- .002 on dimension, or .0008 total parallelism. I'll admit - I am rather inexperienced with CNC milling. I've had to take on the role of programmer due to our previous man leaving, and I really want to try to solve this problem.People assume you can make anything on a CNC but there's still many limitations. The design you want looks cool but is not practical to manufacture. Sure, its technically possible but would cost a fortune to produce. If you had a quarter million dollar five-axis machine, 5 to 10 years experience, and unlimited time- then it might be possibleInside the Z-axis assembly, there was very little room to mount the nut. And since my homemade nut was round, I needed to make a special mount. The mount consists of two pieces of 12mm acrylic. I was able to use the homemade CNC router of my school teacher, to make these parts.I've been working on designing my own 3d printer. Got a few parts that need to be machined. Local shop quotes haven't been good, they don't care for single qty one-offs. I'd rather find another maker/hobbyist who supports the community. West coast preferred but anywhere in the US is fine. The parts are simple, 2d aluminum cuts, 1/4 and 5/16 .

How I use a CNC: Part Two. In the previous post, I gave an overall explanation of the process that I use to make furniture parts with a combination of various power tools and hand tools.Essentially, it’s a hybrid process of power and hand tools that many other professional and hobbyist woodworkers use. If using a CNC to cutout the parts, it should be a very tight fit. In the future graffix, I'll spend more time finding a better photo to use, that way I won't fluster you as much. Cheers Wolffie Whatshammacallit Cut3D, VCarvePro 6.5, Aspire4, PhotoVCarve, Corel Graphics Suite X6. . Here are some custom car parts that you can make with your CNC machine. 1. Dowel Pins. Source:aliexpress.com. Dowel Pins serves as tools that can connect various parts of your vehicle. Since it represents a simple round .

We need this following parts to make this CNC plotter. Parts list: Old DVD writer (2x) Arduino Nano. L293D Motor Driver IC (2x) IC Base (2x) Micro Servo Motor. PCB Board; Male And Female Header Pin. Barrel Socket. Acrylic Sheet 3mm; . And not only complex parts make more sense for CNC machining. For example, a CNC machine can easily fabricate a flat plate by machining stock material to the size and thickness you need. But casting that same plate could . Gun issues aside, [Justin]’s been CNC milling his own gun parts for quite a while. We’ve been a fan of his work simply because of the technical challenge that this sort of milling prese. Building your own CNC machine can be hard, but it can be easy if you have the necessary skills. If you are experienced in metalworking or woodworking, it is much easier. However, if you are new to using CNC machines, It would be best to start by building simple ones. You should also get a CNC kit to make the process easier.

Follow along while we carve this miniature Stratocaster Guitar using our A-Series CNC! This project was carved on 2"x4"x.375" End Grain Oriented Walnut and M.Most of the work I planned to do with the CNC involved milling aluminium parts. An average vise for the machine would be 60 mm high. Since the thickest blocks of aluminium easily available for me would be 60 mm high as well, I chose to space between the work surface and the piece of metal, which could hit the workpiece first, to be 125 mm. . Three: Inspection method of CNC machined parts factory . 1. Basic size and shape check . A: Outer diameter measurement: When measuring the outer diameter, it is necessary to measure and record at two positions in the circumferential direction. When the length of the part diameter is greater than 50mm, the straightness should be checked.(UPDATE: There is now a choice in patterns for the 0.5" MDF layer, you can download one file (CNC-0.5MDF-CutLayout-(Rev3).pdf ) with 35 8.5"x11" pages tiled, or you can download one file (CNC-(One 48x48 Page) 05-MDF-CutPattern.pdf) which has the entire layout on one 48"x48" page to print on a large format printer or tile yourself)

Knowing how to make your CNC machining parts can go a long way in improving your quality of work, saving you money on expensive parts, and adding more fun for yourself into this exciting field. This article provides helpful insights on what it takes to delve into that world. Benefits of CNC Machining Parts Higher CNC machines can make furniture that ranges from simple shelves and desks, to chairs and tables. They can be decorated and carved into whatever kind of shape or design you – or your customer – likes. . And it’s not uncommon for those who regularly work on making CNC projects to have a lot of spare parts, tools and materials lying around.

Furthermore, Arduino can control various CNC machines, ranging from 3D printers to laser cutters. That said, Arduino is the best controller if you want to build a CNC machine. Let's now get started on how to build a simple CNC machine using Arduino. What You Will Need. To create a CNC machine with Arduino, you will need:-An Arduino microcontroller CNC turning involves the use of either CNC lathes or multi-axis CNC turning centers. Manufacturers use CNC lathes to turn materials for cylindrical and concentric features on parts. . The material cools and takes the form of the mold to make the part. After molding, the parts are in a “green state,” meaning that they are in the right .

machine to make your own

homemade cnc router parts

metal l shaped bracket site acehardware.com

homemade cnc parts

$45.99

how to make cnc parts|homemade cnc router parts