beading sheet metal by hand $1,919.99 We sell Western Electric telephones tahat have been restored to like new condition. These are to include phones from the early 190s to the 1950s . They are either bakelite or metals which are sometime brass. All our telephones are original antiques which will go up in value.

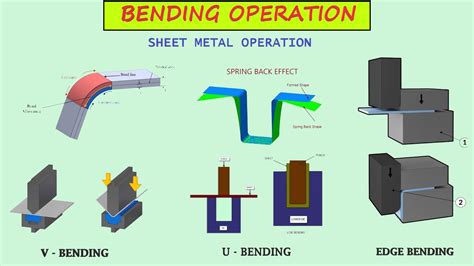

0 · types of sheet metal bending

1 · sheet metal bending standards

2 · sheet metal bending dies

3 · maximum thickness sheet metal bending

4 · bending tool for sheet metal

5 · bending sheet metal 90 degrees

6 · beading process in sheet metal

7 · beading machine for sheet metal

Over the past decade, Fetchen Sheet Metal has strived to become a modern and highly efficient fabrication and installation company in the HVAC Industry. Moving into a large facility with the latest computer driven Plasma Cutting Systems, task specific machinery.

types of sheet metal bending

Sheet Metal Bead Roller Machine, 12" Gear Drive Bench Manual Heavy Duty RM12 Metal Bead Roller Bending Machine with 6 Dies Kit for Vehicle Floor Pans, Trunk Pans, Automotive Industry

Easy to Adjust - Sheet metal brake for clean, crisp bends in metal roofing .9.996.00

septic distribution box hose

sheet metal bending standards

5.009.009.999.99

Follow along to check out how to bead roll your own parts!Roll through heavy gauge sheet metal projects all day long. With a maximum capacity of 12-gauge aluminum or 14-gauge mild steel, the G0816 Heavy-Duty .Choose from our selection of bead rollers, including hand-held sheet metal edge shapers, sheet metal edge shapers, and more. In stock and ready to ship.

Bead Roller Motor Kit is a powerful beading operation among all super bead rollers machines. Strengthens, reinforces, and creates designs on sheet metal for automotive, aeronautical, and HVAC projects.Bead Rollers are designed to create various bead profiles in sheet metal for decorative purposes, strengthening, or metal shaping. We offer electric bead rollers with industrial motors as well as .Our metal forming dies enable you to create deep channels, flanges, and style lines in various sizes. With a bead roller fence, you’ll achieve perfectly straight lines or offsets for precise metal shaping. Explore our special kits for making .

service metals paint & fabrications ltd

The Eastwood Elite 27" Metal Forming Bead Roller Features: Largest Hand Crank Bead Roller on the Market; Fabricated Design for Industry Leading Strength and Rigidity; 27” Throat Capacity – Allows you to form from .

3-Station Edge Roller for Bending Metal Roofing Materials at 0-90° Angle, Large Radius Sheet Metal Bead Roller Bender for Making 1/2-5in (13‑130mm) Bending

9.999.994.999.99

9.99Sheet Metal Bead Roller Machine, 12" Gear Drive Bench Manual Heavy Duty RM12 Metal Bead Roller Bending Machine with 6 Dies Kit for Vehicle Floor Pans, Trunk Pans, Automotive Industry Follow along to check out how to bead roll your own parts!

Roll through heavy gauge sheet metal projects all day long. With a maximum capacity of 12-gauge aluminum or 14-gauge mild steel, the G0816 Heavy-Duty Bead Roller helps ensure you get the right bead the first time.Choose from our selection of bead rollers, including hand-held sheet metal edge shapers, sheet metal edge shapers, and more. In stock and ready to ship.Bead Roller Motor Kit is a powerful beading operation among all super bead rollers machines. Strengthens, reinforces, and creates designs on sheet metal for automotive, aeronautical, and HVAC projects.Bead Rollers are designed to create various bead profiles in sheet metal for decorative purposes, strengthening, or metal shaping. We offer electric bead rollers with industrial motors as well as manual or hand-crank bead rollers.

Our metal forming dies enable you to create deep channels, flanges, and style lines in various sizes. With a bead roller fence, you’ll achieve perfectly straight lines or offsets for precise metal shaping. Explore our special kits for making steps, raised . The Eastwood Elite 27" Metal Forming Bead Roller Features: Largest Hand Crank Bead Roller on the Market; Fabricated Design for Industry Leading Strength and Rigidity; 27” Throat Capacity – Allows you to form from center of a 54” panel; Industry standard 22mm shafts to accept all professional dies; Tool-less design for Quick, Precise .

3-Station Edge Roller for Bending Metal Roofing Materials at 0-90° Angle, Large Radius Sheet Metal Bead Roller Bender for Making 1/2-5in (13‑130mm) Bending

Easy to Adjust - Sheet metal brake for clean, crisp bends in metal roofing materials (e.g. steel/aluminium/Copper etc.), Making 5/8" to 4" (16 to 102 mm) bends in 29 to 22-gauge (0.36 to 0.76 mm) steel. The ER3 is capable of bending straight bends of an infinite length up to 90 degrees.Sheet Metal Bead Roller Machine, 12" Gear Drive Bench Manual Heavy Duty RM12 Metal Bead Roller Bending Machine with 6 Dies Kit for Vehicle Floor Pans, Trunk Pans, Automotive Industry

Follow along to check out how to bead roll your own parts!

Roll through heavy gauge sheet metal projects all day long. With a maximum capacity of 12-gauge aluminum or 14-gauge mild steel, the G0816 Heavy-Duty Bead Roller helps ensure you get the right bead the first time.Choose from our selection of bead rollers, including hand-held sheet metal edge shapers, sheet metal edge shapers, and more. In stock and ready to ship.Bead Roller Motor Kit is a powerful beading operation among all super bead rollers machines. Strengthens, reinforces, and creates designs on sheet metal for automotive, aeronautical, and HVAC projects.

Bead Rollers are designed to create various bead profiles in sheet metal for decorative purposes, strengthening, or metal shaping. We offer electric bead rollers with industrial motors as well as manual or hand-crank bead rollers.

Our metal forming dies enable you to create deep channels, flanges, and style lines in various sizes. With a bead roller fence, you’ll achieve perfectly straight lines or offsets for precise metal shaping. Explore our special kits for making steps, raised . The Eastwood Elite 27" Metal Forming Bead Roller Features: Largest Hand Crank Bead Roller on the Market; Fabricated Design for Industry Leading Strength and Rigidity; 27” Throat Capacity – Allows you to form from center of a 54” panel; Industry standard 22mm shafts to accept all professional dies; Tool-less design for Quick, Precise .3-Station Edge Roller for Bending Metal Roofing Materials at 0-90° Angle, Large Radius Sheet Metal Bead Roller Bender for Making 1/2-5in (13‑130mm) Bending

sheet metal bending dies

To fix warped sheet metal after welding, you can follow a few steps. Firstly, use a torch or flame to heat the warped area of the sheet metal. Once heated, rapidly cool the area with water or compressed air to help reposition the metal. Next, combine excessive heating with hammering or striking the sheet metal in the opposite direction of the warp.

beading sheet metal by hand|types of sheet metal bending