bending formula in sheet metal Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . I explore a complete of CNC M Codes and look at their function and how we use them on both CNC lathes and CNC milling machines.

0 · sheet metal setback chart

1 · sheet metal flat length calculation

2 · sheet metal bending calculation formula

3 · sheet metal bending calculation excel

4 · sheet metal bending allowance chart

5 · how to calculate bending angle

6 · calculating bend allowance sheet metal

7 · bending calculation for sheet metal

Metal fabrication is the processing of metals to create various metal objects. The process of metal fabrication can happen in one step or can even take tens of steps, depending on what is required.Forming converts flat sheet metal into 3-D parts by applying force without adding or removing material. The force must be great enough to change the metal's initial shape. Forming can be controlled with tools such as punches and dies. Machinery can regulate force magnitude and direction. Machine-based forming can combine forming and welding to produce lengths of fabricated sheeting (e.g. linear grating for water drainage). Most metallic materials, being at leas.

sheet metal setback chart

junction box for washing machine

sheet metal flat length calculation

Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time. Step-1: Calculate the value bend allowance for the required sheet metal bend by using the below formula. Bend Allowance (BA) = (Π/180) × ( R + K×T) × A Step-2: Calculate the value of bend deduction from the values of bend allowance and outside setback. Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .

Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time.Step-1: Calculate the value bend allowance for the required sheet metal bend by using the below formula. Bend Allowance (BA) = (Π/180) × ( R + K×T) × A Step-2: Calculate the value of bend deduction from the values of bend allowance and outside setback. Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! Want to learn how to calculate bending allowance, bending deduction, and K-factor for sheet metal bending? Our guide offers a step-by-step process and practical tips to help you achieve accurate and precise bending results every time.

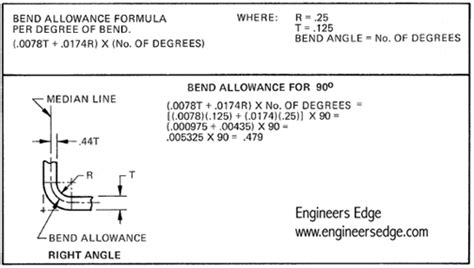

junction box for woods 6 ft mower

Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Bend allowance, while being oftentimes tricky to determine for all cases, is fairly easy to predict and calculate for many standard circumstances.The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend allowance calculator.The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. You will need to know your Material Thickness (MT), the Bend Angle (B<), the Inside Radius (IR), and the K-Factor (K). Knowing the k-factor formula is essential in order to bend any kind of sheet metal correctly; in fact, it varies according to the type of material to be deformed. What is the k-factor? The k-factor indicates the behaviour of the material being bent and how it reacts to the applied tensile and compressive stresses.

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time.Step-1: Calculate the value bend allowance for the required sheet metal bend by using the below formula. Bend Allowance (BA) = (Π/180) × ( R + K×T) × A Step-2: Calculate the value of bend deduction from the values of bend allowance and outside setback.

Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.

With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

Want to learn how to calculate bending allowance, bending deduction, and K-factor for sheet metal bending? Our guide offers a step-by-step process and practical tips to help you achieve accurate and precise bending results every time.

Bend allowance is a term which describes how much material is needed between two panels to accommodate a given bend. Bend allowance, while being oftentimes tricky to determine for all cases, is fairly easy to predict and calculate for many standard circumstances.

The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend allowance calculator.The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. You will need to know your Material Thickness (MT), the Bend Angle (B<), the Inside Radius (IR), and the K-Factor (K).

I have a VPI classic 1 with Valhalla wiring. Currently have a rca junction box and considering changing for XLR. My only reservation is needing to upgrade wiring along with the junction box. For my taste an approximate $1000.00 upgrade. I love the sound now, would be worth upgrading?

bending formula in sheet metal|bending calculation for sheet metal