cnc machine vs plasma cutter The Key Differences: Plasma Cutting: Using ionized gas to not just melt but blow away metal like a pro. Laser Cutting: This one’s all about focused light—it melts or vaporizes .

Browse our inventory of used CNC machines for sale and trust your next project with premier equipment’s listing and auctions. Modern used CNC lathes and turning centers provide a simulated visualization of the machine’s process and require less intimate knowledge of CNC operation than older types.

0 · cnc plasma cutting machine hobby

1 · cnc plasma cutter hobby

2 · cnc plasma cutter for hobbyist

3 · best cnc plasma cutting machine

4 · best budget hobby plasma cutter

5 · best affordable cnc plasma cutter

6 · affordable cnc plasma cutting tables

7 · affordable cnc plasma cutter

$375.00

cnc plasma cutting machine hobby

Depending on material thickness, plasma can cut up to 200 ipm (inches per minute). Laser cutters and their technology are quickly competing with the cutting speeds of plasma cutters. CNC Fiber Laser tables are slightly faster than CO2 cutters on all thicknesses. Introduction. Proper cutting method selection will ensure the job is completed both efficiently and accurately. Plasma cutting of electricity-conducting materials occurs with a hot . Cutting Speed. Generally, laser cutters offer higher cutting speeds than plasma cutters. This is because the laser beam has a significantly higher power density, allowing rapid .

Laser cutting machines cut through materials using a narrow and intense ray of light, but plasma cutters emit a directed flow of plasma instead. Both methods are mainly used to cut metals, but laser cutting can also be .CNC plasma cutting machines are generally less expensive than laser cutting machines. Plasma cutters have high cutting speeds even on thicker metals. They can cut various metals easily ranging from thin to thick. CNC plasma cutters .

galvanized sheet metal backsplash

The Key Differences: Plasma Cutting: Using ionized gas to not just melt but blow away metal like a pro. Laser Cutting: This one’s all about focused light—it melts or vaporizes .Today’s plasma and laser cutting machines are both highly precise thanks to computer numeric control (CNC), but both have distinct advantages and excel at different applications.

1. Versatility: CNC plasma cutting machines can cut through a wide range of metals, including steel, aluminum, brass, copper, and others. 2. Cutting speed: Plasma cutting machines can cut through thicker metals at a . Simply put, a CNC plasma cutting machine uses the power of electrical current and compressed gas to cut through metal. Plasma cutting technology was first developed in the 1950s in order to cut copper, stainless .To simplify your selection, this article will examine three different brands of plasma cutters: the Arcrdoid, the Unimig Stealth, and the KT Series. What is a CNC Plasma Cutter? A CNC plasma cutter is a thermal fabrication tool that .

This manual will help you to learn the practical guide to CNC plasma cutting machine installation, debugging and operation tips with a comprehensive instructional video. Post Your Review. 1 to 5-star rating 5 stars . CNC machines may attain tolerances of ±0.001 inches, making them suitable for elaborate designs. Automated cutting procedures save production time and labour costs while cutting a wide range of materials and . In this article, we will discuss the topic about laser cutter vs. plasma cutter, two of the most commonly used technologies in metal fabrication. . Choosing between a CNC laser cutting machine and a plasma cutter depends largely on the type and thickness of the material you’re cutting, as well as the precision requirements of your project. Some of the best plasma cutters even have built-in air compressors to make the process simpler. If you enjoyed this ranking of the best plasma cutters, you may also enjoy: The best CNC machines buyer’s guide; The best 4×8 CNC routers; Our buyer’s guide for the best laser cutters and engravers

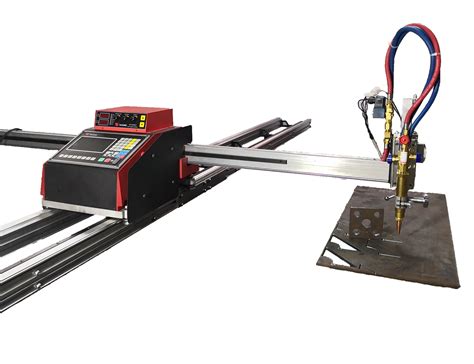

A CNC (Computer Numerical Control) plasma cutter is a machine that uses a plasma torch to cut metal. It is controlled by a computer, which allows for precise and intricate cuts. CNC plasma cutters are commonly used in industrial settings for cutting metal plates, pipes, and other components.

Plasma cutters are often somewhat cheaper to get started. Introductory-level handheld plasma cutting systems can be as little as 0-0. Much larger systems, including industrial CNC machines, can be between ,000 and ,000.cnc plasma cutting machine factory is an online marketing agent of China plasma cutting machine factory. In the process of 16 years’ development, we have mastered the advanced technology and mature service system. We not only accept bulk orders from agents, but also accept customized orders for some special models, we will customize the . Plasma Cutting Machine: Type: Plasma cutting machines use a high-velocity jet of ionized gas to melt and cut through metal. Materials: Commonly used for cutting steel, stainless steel, and aluminum. Advantages: Plasma cutting is known for its speed and can handle thick metal sheets efficiently. Between Plasma Cutter and Laser Cutter Technology:Ive done extensive 3d printing work as well as worked with Haas CNC machines doing firearms manufacture for a while as a weekend job. I see theres a crossfire plasma cutting table around the 1500 mark, and im seeing videos of guys building their own, thats bigger, for around k.

3. There are system configurations from Hypertherm that come with both a hand torch and a machine torch. The idea is to leave the machine torch mounted on your cnc machine. Unplug the machine torch from the plasma power supply, plug in the hand torch and you are ready for hand cutting. How Does A CNC Plasma Cutting Machine Work? The CNC plasma cutting machine is a new type of thermal cutting equipment. Its working principle is to use the heat of the high-temperature plasma arc to locally melt the metal at the incision of the workpiece, and use the momentum of the high-speed plasma to remove the molten metal to form an incision. Computer Controlled (CNC) plasma cutting is one of the fastest and most affordable techniques for producing metal parts. In recent years, there has been a flood of self-proclaimed “CNC-ready” plasma cutters for sale on Amazon and eBay. . Manual vs. Machine Torches. Plasma cutter power supplies marketed for manual operation often cost .

The laser beam is focused into tiny points, resulting in a narrow cutting slot for the laser cutting machine. In contrast, the plasma cutting machine’s cutting slot is slightly wider. Laser cutting machines have a faster cutting speed, with some machines capable of reaching speeds of up to 10 meters per minute, compared to plasma cutting . Slow down the cut speed (as when cornering on a cnc machine) and the voltage increases and the amperage droops. There are still transformer based droopers. Poor cut quality, extremely short consumable life. The most popular drooper plasma cutters were the Thermal Dynamics PAC3xr, PAC5xr and PAC10xr).

cnc plasma cutter hobby

cnc plasma cutter for hobbyist

Somehow I managed to miss the notes of compatibility issues with HF start plasma cutters and CNC machines, it turns out my trusty little Zeny Cut50 is high frequency. Can anyone recommend a low cost machine that’s .

Differences Between Plasma and Water Jet Cutting Quality. The plasma cutter can produce smooth cuts in many steels, with an accuracy of +/- .01” – .030” depending on the setup. As material thickness increases, the cut .In the critical decision-making process of Plasma Cutting vs. Oxygen Cutting for your fabrication needs, the choice is pivotal and hinges on a multitude of factors.This choice hinges on a multitude of factors, such as the specific metal in question, the material’s thickness, and the financial implications. Oxy-fuel cutting emerges as the superior method for handling robust, thicker metals. StyleCNC is a well-known and respected manufacturer of hobbyist and mid-range CNC machines, and its 4×4 CNC plasma table is one of the top beginner models you can buy.. This cheap CNC plasma cutter ticks about every box you could want as a novice. It’s easy to install, use, and maintain, it’s made using top-quality components for great reliability, and is . The CNC plasma cutting machine is a type of thermal cutting equipment. Its working principle is to melt the metal at the incision of the workpiece with the high-temperature plasma arc heat. . Fiber Laser Vs. Plasma Cutting • Compared with plasma cutting, fiber laser cutting is much more accurate, and the heat-affected area and gap are much .

Additions – i.e. additional cutting heads, gas torches (for plasma), zoom vs non-zoom cutting heads (for laser) Table 5 shows the estimated acquisition cost for a fiber laser and plasma machine. For more information, please also check out our dedicated article on the price of a CNC plasma cutting machine. Using a laser with a power of 1000W to cut a 2mm thick low-carbon steel plate, the cutting speed can reach 600cm/min. Cutting 5mm thick polypropylene resin board, the cutting speed can reach 1200cm/min. Plasma cutting has slow cutting speed and relatively low precision, and is more suitable for cutting thick plates, but the end face has a slope.

This portable plasma cutter seems like a well-built machine for everyday needs, metal fabrication, home shop cutting, or metal artwork applications. However, there are no modern features such as a non-touch pilot arc, built-in air compressor, or CNC table compatibility. A cnc machine that can cut metal is necessary for metal fabrication shops. Generally, we have three kinds of machines that can do this job: cnc oxy-fuel cutting by Oxyacetylene, cnc plasma cutter machine, and fiber laser cutting machine. A fiber laser cutting machine is necessary if you have extremely high requirements for cutting speed and .

Depending on machine size you can build your machine with 1500$ (4x4) or 1800$ (4x8) You can use rest of money to buy a good plasma source. 07-28-2012, 11:36 AM #6 ed_v On cnc machines there had to be careful grounding as well as isolation to protect the system cnc controller from damage caused by the high frequency and its electrical noise emission. - In the early 1990's Hypertherm developed the first air plasma torch that had a strong pilot arc that could transfer to the metal regardless of surface condition .

When comes to investing in a CNC plasma vs waterjet cutting machine the plasma cost is lower. Acquiring a professional CNC plasma cutter costs anywhere between ,000 to 0,000. A waterjet cutter cost is infinitely more expensive, costing between 0,000 to 0,000. So for upfront costs, plasma-cutting machines are cheaper.

galvanised steel tool boxes

$326.12

cnc machine vs plasma cutter|best cnc plasma cutting machine