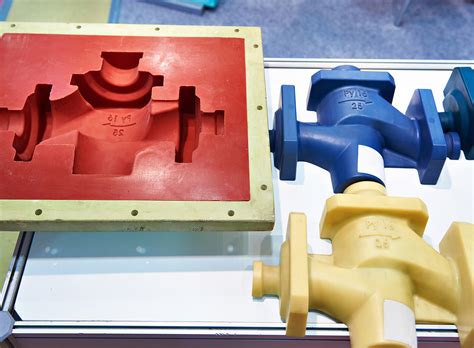

customized injection machine molded part Our in-house tooling and design experts handle custom injection molding and plastic part design with quality and precision, lowering your labor costs, saving you time and money. We can produce high quantities of parts at a fraction of the cost without compromising quality. There is probably a check box under box 2 that says taxable amount not determined. ML may not know what your cost basis is in the 401(k) so they make you calculate the taxable amount. IRS isn't going to help you with this.

0 · how custom injection molding works

1 · customized plastic injection moulded parts

2 · customized low cost injection molding

3 · custom molds for injection molding

4 · custom injection molding usa

5 · custom injection molding near me

6 · custom injection molding manufacturers

7 · comprehensive injection molding services

Circuit breakers are necessary to prevent electrical problems, expensive damage, and most importantly fires. It can be alarming when your circuit breaker keeps tripping when there is nothing plugged in. Follow along as we explore what it means when your circuit breaker trips for no apparent reason.

Custom injection molded parts for serial production. The Process: Use the Bearing Designer Tool to input your bearing type, materials & dimensions; Choose from over 20 iglide® materials & 6 geometries based on your .Our in-house tooling and design experts handle custom injection molding and plastic part design with quality and precision, lowering your labor costs, saving .Custom injection molded parts for serial production. The Process: Use the Bearing Designer Tool to input your bearing type, materials & dimensions; Choose from over 20 iglide® materials & 6 geometries based on your application, industry & requirements; See immediate pricing; Download drawings & 3D models of your part; Samples shipped to you in .

Our in-house tooling and design experts handle custom injection molding and plastic part design with quality and precision, lowering your labor costs, saving you time and money. We can produce high quantities of parts at a fraction of the cost without compromising quality.

Custom injection molding services for overmolding, and thermoplastic and insert molding. Xometry's global network of molding suppliers leads in prototypes, low-volume & mass production parts. Get custom plastic molded prototypes and production parts in as few as five business days.MSI Mold has 30 years experience with custom plastic and injection molding. Contact us today to find out more!Our plastic injection molding process produces custom prototypes and end-use production parts with lead times as fast as 1 day. We use aluminum molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock about 200 different thermoplastic resins.

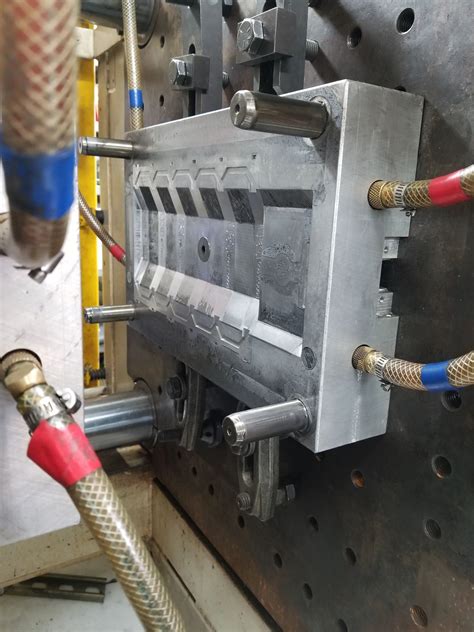

Fictiv now provides automated DFM feedback for injection molding during the initial quoting process. Our network of high quality injection molding partners spans the globe, with production available in the US, Mexico, and China -- so you can optimize production for costs, lead time, or both as needed.Experts in the production of highly complex plastic injection molded parts and assemblies needed for medical, aerospace/defense, automotive and electronics.We can handle almost any project – from custom plastic injection molding and plastisol dip coating, to medical device contract manufacturing services for products like catheters and airway management devices. We pride ourselves in our extensive custom capabilities and .In combination with skilled mold designers, software technology, and the use of expensive CNC machinery, MSI builds molds for plastic injection that are used to produce high quality molded plastic parts.

At Plastic Molded Concepts (PMC), we specialize in custom plastic injection molding services for a wide range of industries. The injection molding process involves heating resin and injecting it into a mold cavity to create precise plastic parts.

how custom injection molding works

Custom injection molded parts for serial production. The Process: Use the Bearing Designer Tool to input your bearing type, materials & dimensions; Choose from over 20 iglide® materials & 6 geometries based on your application, industry & requirements; See immediate pricing; Download drawings & 3D models of your part; Samples shipped to you in .Our in-house tooling and design experts handle custom injection molding and plastic part design with quality and precision, lowering your labor costs, saving you time and money. We can produce high quantities of parts at a fraction of the cost without compromising quality.

china cnc laser cutting machine operator vacancy

Custom injection molding services for overmolding, and thermoplastic and insert molding. Xometry's global network of molding suppliers leads in prototypes, low-volume & mass production parts. Get custom plastic molded prototypes and production parts in as few as five business days.MSI Mold has 30 years experience with custom plastic and injection molding. Contact us today to find out more!Our plastic injection molding process produces custom prototypes and end-use production parts with lead times as fast as 1 day. We use aluminum molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock about 200 different thermoplastic resins.

Fictiv now provides automated DFM feedback for injection molding during the initial quoting process. Our network of high quality injection molding partners spans the globe, with production available in the US, Mexico, and China -- so you can optimize production for costs, lead time, or both as needed.Experts in the production of highly complex plastic injection molded parts and assemblies needed for medical, aerospace/defense, automotive and electronics.We can handle almost any project – from custom plastic injection molding and plastisol dip coating, to medical device contract manufacturing services for products like catheters and airway management devices. We pride ourselves in our extensive custom capabilities and .

customized plastic injection moulded parts

In combination with skilled mold designers, software technology, and the use of expensive CNC machinery, MSI builds molds for plastic injection that are used to produce high quality molded plastic parts.

customized low cost injection molding

china cnc glass loading cutting machine

china cnc fiber laser 1000w manufacturers

Some of the electricians on our project are under the impression that any unused openings in their junction boxes are considered effectively sealed/closed by the installation of the external fire pads and do not require an actual KO seal prior to the installation of the fire pad.

customized injection machine molded part|custom molds for injection molding